High-fluidity antibacterial halogen-free flame retardant composite material and preparation method thereof

A technology of composite materials and flame retardants, applied in the field of modified polypropylene materials and its preparation, can solve the problems of low flame retardant efficiency, large amount of addition, low density, etc., to improve flame retardant performance, save costs, and optimize formula Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

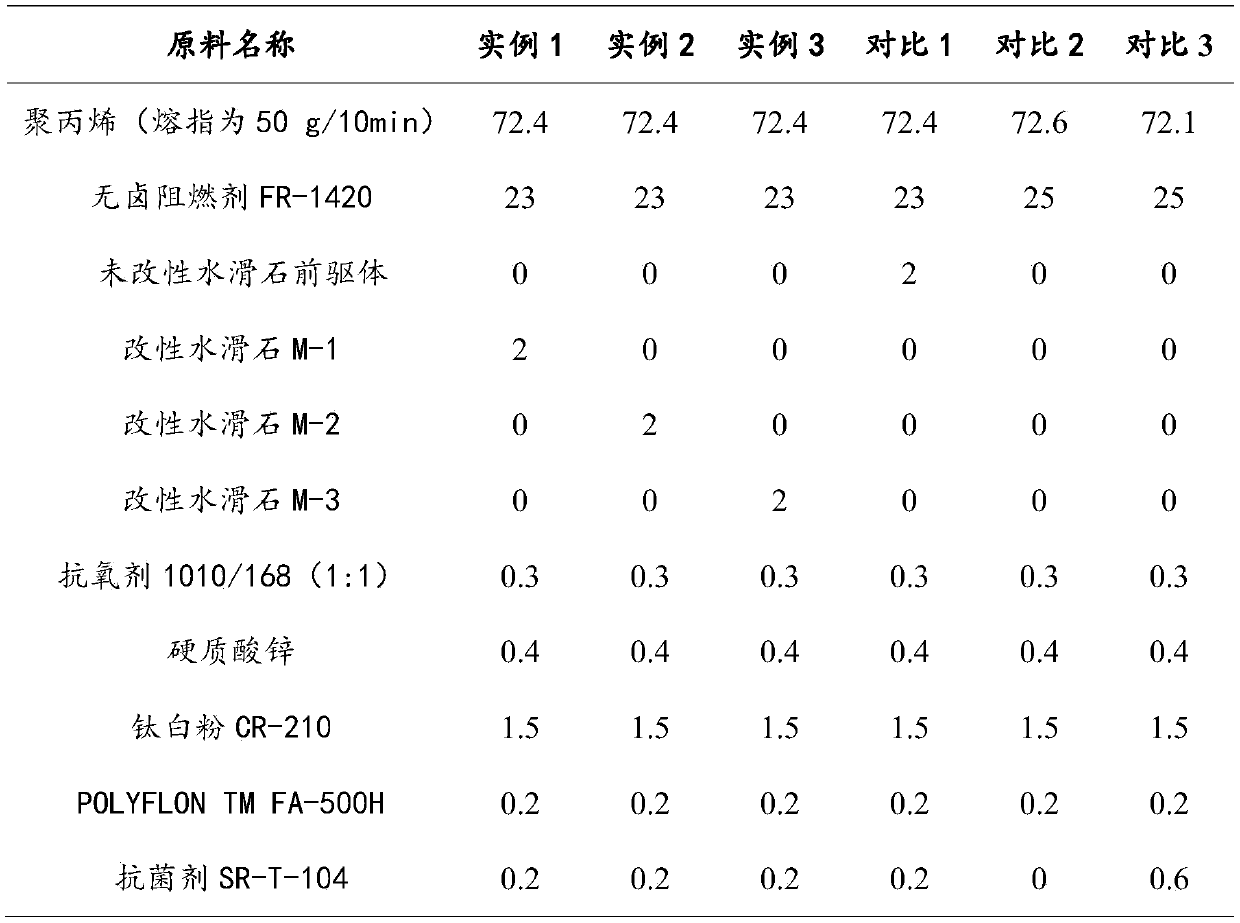

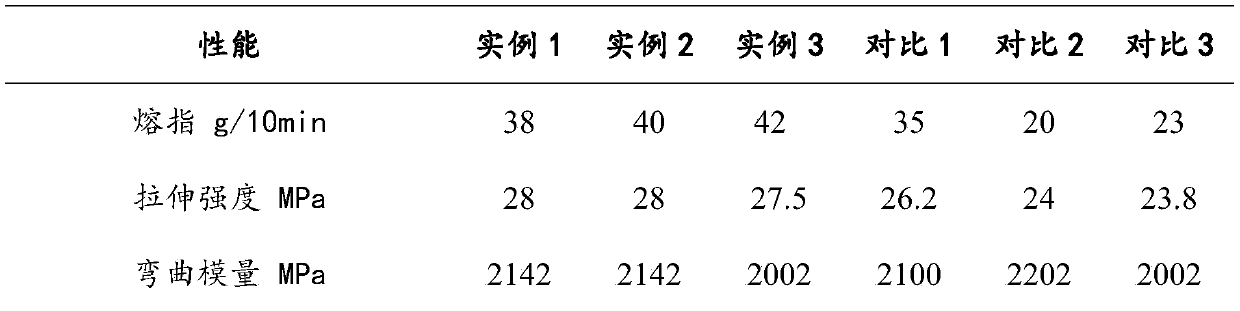

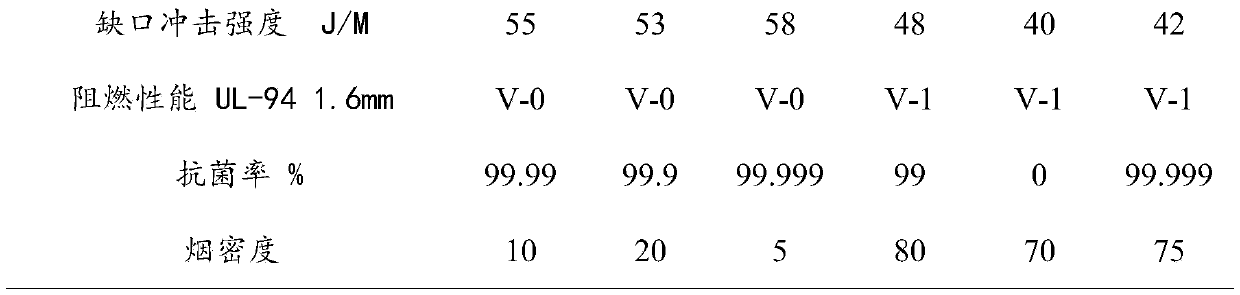

Embodiment 1

[0059] (1) Preparation process of modified hydrotalcite M-1

[0060] Weigh 10 g of hydrotalcite precursor Mg-Al-LDHs (CO 3 2- ) and 20g of AgNO 3 , the mass ratio between the two is 1:2, the two are mixed evenly, and then placed in a muffle furnace for calcination at 450°C for 2h, to prepare a double metal oxide loaded with silver ions.

[0061] b. Weigh 10 g of the double metal oxide loaded with silver ions in step a, then grind it to a size larger than 300 mesh, add 500 ml of distilled water and stir evenly to prepare a hydrotalcite suspension slurry.

[0062] c. According to the weight ratio of 1:1.2, weigh the amount of ammonium octamolybdate to be 12g, then add 300ml of distilled water to make a soluble salt solution, and then slowly add it to the hydrotalcite suspension in step b through a constant pressure dropping funnel , nitrogen protection, stirring at 80°C for 6h.

[0063] d. After the stirring is completed, crystallize at 90°C for 12 hours, then filter, wash, ...

Embodiment 2

[0068] (1) Preparation process of modified hydrotalcite M-2

[0069] a. Weigh 15g of the hydrotalcite precursor Mg-Al-LDHs (CO 3 2- ) and 15g of AgNO 3 , The weight ratio between the two is 1:1, the two are mixed evenly, and then put into a muffle furnace for calcination at 500°C for 2h, to prepare a double metal oxide loaded with silver ions.

[0070] b. Weigh 10 g of the double metal oxide loaded with silver ions in step a, then grind to a size larger than 300 mesh, add 500 ml of distilled water and stir evenly to prepare a hydrotalcite suspension slurry.

[0071] c. According to the weight ratio of 2:1, weigh the amount of ammonium octamolybdate to be 5g, then add 300ml of distilled water to make a soluble molybdate solution, and then slowly add the hydrotalcite suspension in step b through the constant pressure dropping funnel solution, under nitrogen protection, and stirred at 80°C for 6h.

[0072] d. After the stirring is completed, crystallize at 90°C for 12 hours, ...

Embodiment 3

[0077] (1) Preparation process of modified hydrotalcite M-3

[0078] a. Weigh 10g of hydrotalcite precursor Mg-Al-LDHs (CO 3 2- ) and 15g of AgNO 3 , the weight ratio between the two is 1:1.5, the two are mixed uniformly, and then put into a muffle furnace for calcination at 550° C. for 2 hours to prepare a double metal oxide loaded with silver ions.

[0079] b. Weigh 10 g of the double metal oxide loaded with silver ions in step a, then grind to a size larger than 300 mesh, add 500 ml of distilled water and stir evenly to prepare a hydrotalcite suspension slurry.

[0080] c. According to the weight ratio of 1:2, weigh the amount of ammonium octamolybdate to be 20g, then add 300ml of distilled water to make a soluble molybdate solution, and then slowly add it to the hydrotalcite suspension in step b through a constant pressure dropping funnel solution, under nitrogen protection, and stirred at 80°C for 6h.

[0081] d. After the stirring is completed, crystallize at 90°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com