Method for preparing high thermal conductivity heating film material

A technology of heating film and high thermal conductivity, which is applied in the field of thermal conductivity materials, can solve the problems of low thermal conductivity and achieve the effects of improving thermal conductivity, reducing resistivity, and improving electrothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

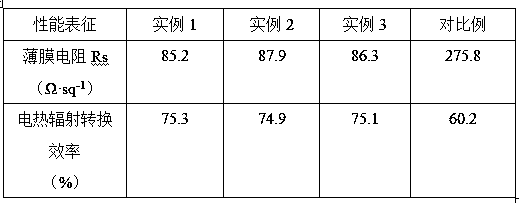

Examples

Embodiment Construction

[0028]In parts by weight, weigh 45-50 parts of n-butanol, 3-5 parts of 200-mesh magnesium powder, and 10-15 parts of 200-mesh aluminum powder in a mortar, grind and disperse to obtain a dispersion slurry, and 1:15, add elemental iodine to the dispersion slurry, stir and mix, and place it at 45-50°C for 1-2 hours to insulate and react for 1-2 hours to obtain a reaction solution; put the reaction solution at 45-55°C and rotary evaporate to the volume of the reaction solution 1 / 5, to obtain the rotary distillation solution and add the rotary distillation solution to absolute ethanol according to the mass ratio of 1:10, stir and mix to obtain the modified solution, and weigh 45 to 50 parts of the modified solution according to parts by weight , 10-15 parts of acetylacetone and 65-70 parts of 75% ethanol solution by mass fraction are placed in a beaker, stirred and mixed and left to stand for 2-3 hours to obtain a sol solution, and the sol solution is dried at 100-110°C for 1-2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com