Novel anti-fouling multifunctional microporous diatom ecological brick preparation method

An ecological brick and multi-functional technology, which is applied in the field of preparation of new anti-fouling multifunctional microporous diatom ecological bricks, can solve the problems of not easy to be cleaned, low level of formula technology, poor dirt resistance of the surface of diatom ecological bricks, etc., to improve the durability The effect of detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

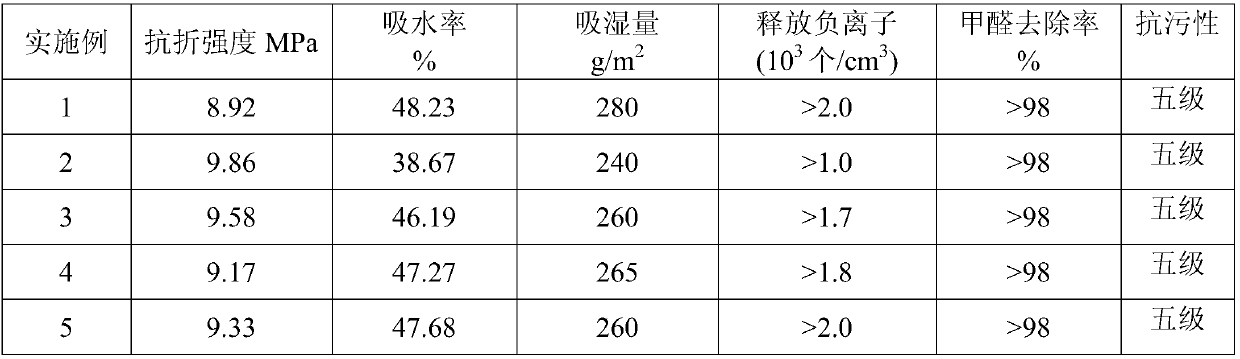

Examples

Embodiment 1

[0027] A method for preparing a novel antifouling multifunctional microporous diatom ecological brick, the method is realized through the following specific steps and process conditions:

[0028] a) Blank preparation: According to the percentage by mass, take 57% of diatomite, 10% of spherical clay, 0% of wollastonite, 2% of talc, 20% of feldspar, 1% of sodium carbonate, and 10% of coke gem, add water ball mill, The ball milling time is 2 hours, the moisture content is 50%, pass through a 40-mesh sieve, and the slurry is discharged and stirred for later use;

[0029] b) Glaze preparation: according to the percentage by mass, take 10% of diatomite, 73% of frit, 10% of kaolin, 5% of talc, 2% of sodium carbonate, and add 1% of photocatalyst and 2.5% of negative ion powder to the above raw materials , add water ball mill, the ball milling time is 24 hours, the water content is 50%, remove iron after ball milling, and pass through a 200-mesh sieve;

[0030] c) Billet granulation: ...

Embodiment 2

[0036] A method for preparing a novel antifouling multifunctional microporous diatom ecological brick, the method is realized through the following specific steps and process conditions:

[0037] a) Blank preparation: According to the percentage by mass, take 35% of diatomite, 25% of ball clay, 10% of wollastonite, 3% of talc, 15% of feldspar, 3% of sodium carbonate, and 9% of coke gem, add water ball mill, The ball milling time is 4 hours, the water content is 55%, pass through a 40-mesh sieve, and the slurry is discharged and stirred for later use;

[0038] b) Glaze preparation: according to the percentage by mass, take 15% of diatomite, 64% of frit, 10% of kaolin, 10% of talc, 1% of sodium carbonate, and add 2.5% of photocatalyst and 1% of negative ion powder to the above raw materials , add water ball mill, ball milling time is 30 hours, water content is 60%, remove iron after ball milling, and pass through 200 mesh sieves; c) blank granulation: add 1% dispersing agent in ...

Embodiment 3

[0044] A method for preparing a novel antifouling multifunctional microporous diatom ecological brick, the method is realized through the following specific steps and process conditions:

[0045] a) Blank preparation: According to the percentage by mass, take 50% of diatomite, 10% of ball clay, 10% of wollastonite, 4% of talc, 15% of feldspar, 3% of sodium carbonate, and 8% of coke gem, add water ball mill, The ball milling time is 3 hours, the moisture content is 53%, pass through a 40-mesh sieve, and the slurry is discharged and stirred for subsequent use;

[0046]b) Glaze preparation: according to the percentage by mass, take 20% of diatomite, 61% of frit, 8% of kaolin, 8% of talc, 3% of sodium carbonate, and add 2% of photocatalyst and 2% of negative ion powder to the above raw materials , adding water ball mill, the ball milling time is 27 hours, the water content is 55%, iron removal after ball milling, and pass through 200 mesh sieve;

[0047] c) Billet granulation: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com