Synthesis method of medium-chain triglyceride

A technology of triglyceride and synthesis method, applied in the field of medicine, can solve the problems of only reaching about 85%, low oil content, high cost, etc., and achieve the effects of improving yield, improving conversion rate and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

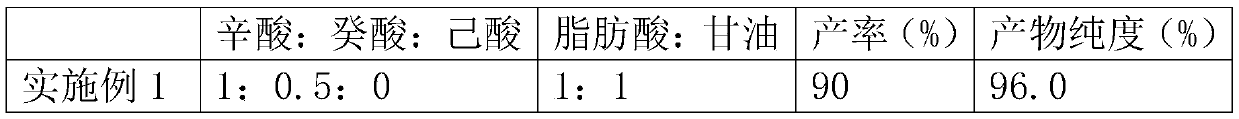

Examples

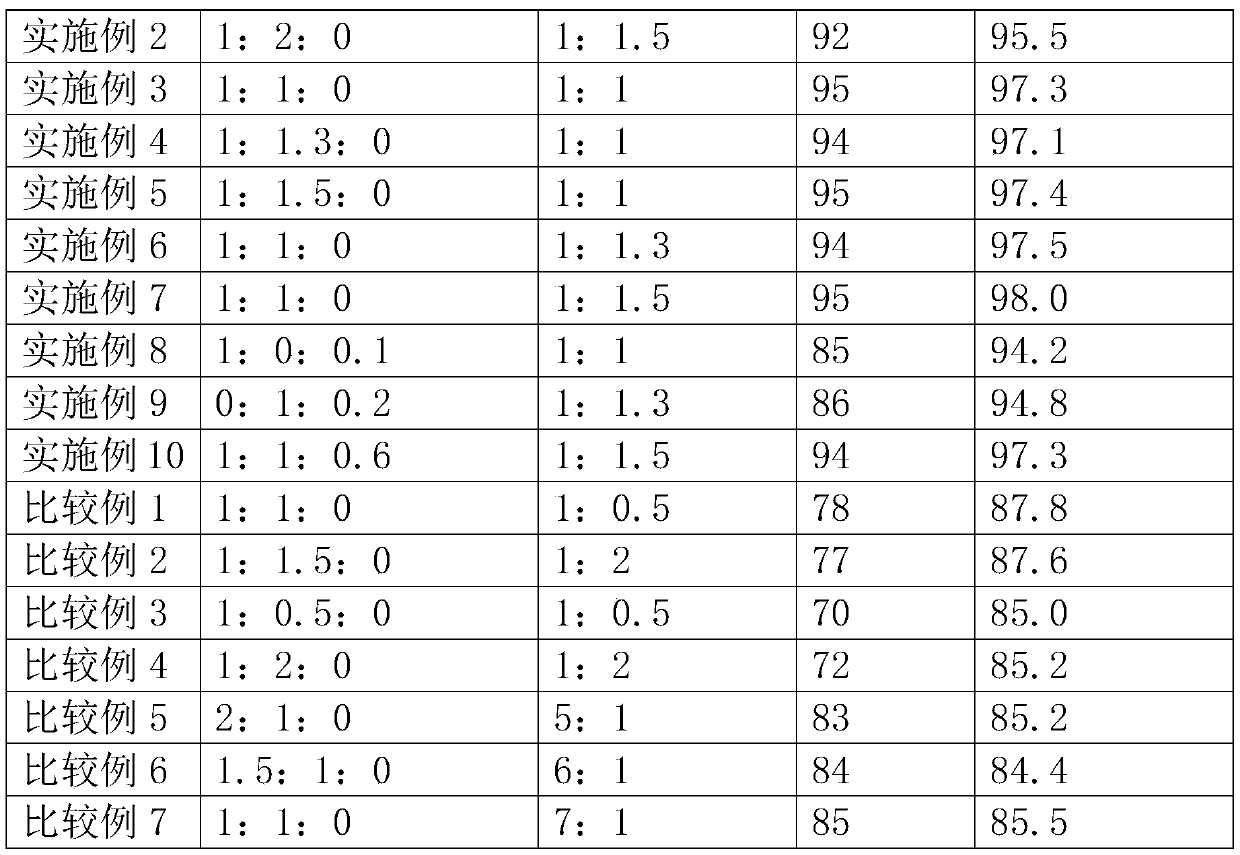

Embodiment 1

[0035] A synthetic method for medium-chain triglycerides, comprising the following steps:

[0036] S1. Take 100g of caprylic acid, 50g of capric acid and 150g of glycerin and mix them uniformly at a temperature of 150°C and a pressure of -0.1MPa to form a mixture;

[0037] S2. Add 1.5 g of catalyst methyl sulfonate to the mixture formed by mixing S1, control the reaction temperature to 160°C, and control the reaction time to 11 hours. After the reaction, the product is distilled out by distillation to obtain the product medium-chain triglyceride ester. The reaction yield was 90%, and the product purity was 96.0%.

Embodiment 2

[0039] A synthetic method for medium-chain triglycerides, comprising the following steps:

[0040] S1. Take 100g of caprylic acid, 200g of capric acid and 450g of glycerin and mix them uniformly at a temperature of 280°C and a pressure of 0.05MPa to form a mixture;

[0041] S2. Add 7.5g of catalyst methyl sulfonate to the mixture formed by mixing S1, control the reaction temperature to 180°C, and control the reaction time to 7 hours. After the reaction, the product is distilled out to obtain the product medium-chain triglyceride ester. The reaction yield was 92%, and the product purity was 95.5%.

Embodiment 3

[0043] A synthetic method for medium-chain triglycerides, comprising the following steps:

[0044] S1. Take 100g of caprylic acid, 100g of capric acid and 200g of glycerin and mix them uniformly at a temperature of 160°C and a pressure of -0.05MPa to form a mixture;

[0045] S2. Add 8 g of catalyst methyl sulfonate to the mixture formed by mixing S1, control the reaction temperature to 160° C., and react for 10 hours. After the reaction, the product is distilled out by distillation to obtain the product medium-chain triglyceride;

[0046] S3. Take the product and add water to wash it. After standing for stratification, release the water. After repeating the above operation 5 times, take the product and dry it to obtain the final product. The reaction yield was 95%, and the product purity was 97.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com