Preparation method of manganese-loaded waste mushroom dreg biomass active carbon for efficiently removing aniline in water body

A technology for waste bacterial residue and biomass, which is applied in water pollutants, chemical instruments and methods, and alkali metal compounds, etc., can solve the problems of complex process, secondary pollution, and high treatment costs, achieve good selective adsorption, and improve removal. efficiency, reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

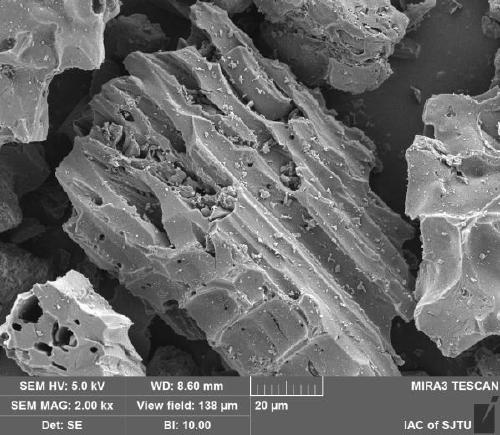

[0021] Peel, crush, wash, dry, and pass through a 10-mesh sieve to obtain the preparatory material for waste fungal residue; take 10g of the preparatory material for waste fungal residue and mix it with zinc chloride solution in a mass ratio of 1:1 , impregnated for 12 hours, carbonized at 300°C for 1 hour, activated at 600°C for 2.5 hours, rinsed with HCl solution with a volume ratio of 3%, dried at 50°C for 12 hours, crushed, and passed through a 80-mesh sieve to make waste bacteria residue Biomass activated carbon. Then, according to the added amount of 12.5mL 高锰酸钾溶液 / g 废菌渣生物质活性炭料 , add the activated carbon of waste bacteria residue biomass into the potassium permanganate solution with a concentration of 0.03mol / L, stir for 24 hours at a speed of 100r / min, carry out manganese doping modification, filter, and bake at a temperature of 350°C The solid product was calcined for 3 hours, and then ground to obtain manganese-loaded waste bacterial residue biomass activated carbon...

Embodiment 2

[0024] Peel, crush, wash, dry, and pass through a 15-mesh sieve to obtain the preparation material of waste fungus residue; take 10g of the preparation material of waste fungus residue and zinc chloride solution in a mass ratio of 1:3 and mix evenly , impregnated for 8 hours, carbonized at 200°C for 3 hours, activated at 500°C for 3 hours, rinsed with 4% HCl solution by volume, dried at 80°C for 8 hours, crushed, and passed through a 120-mesh sieve to make waste bacterial residue Substance activated carbon. Then, according to the added amount of 12.5mL 高锰酸钾溶液 / g 废菌渣生物质活性炭料 , add the activated carbon of waste slag biomass to the potassium permanganate solution with a concentration of 0.04mol / L, stir for 20h at a speed of 200r / min, carry out manganese doping modification, filter, and bake at a temperature of 450°C The solid product was calcined for 1 h, and then ground to obtain manganese-loaded waste bacterial residue biomass activated carbon for the adsorption of aniline.

...

Embodiment 3

[0027] Peel, grind, clean, dry, and pass through a 20-mesh sieve to obtain the preparation material of waste fungus residue; take 10g of the preparation material of waste fungus residue and zinc chloride solution in a mass ratio of 1:1 and mix evenly , impregnated for 12 hours, carbonized at 300°C for 1 hour, activated at 700°C for 0.5 hours, rinsed with HCl solution with a volume ratio of 5%, dried at 50°C for 12 hours, crushed, and passed through a 100-mesh sieve to make waste bacteria residue Biomass activated carbon. Then, according to the added amount of 12.5mL 高锰酸钾溶液 / g 废菌渣生物质活性炭料 , add the activated carbon of waste slag biomass to the potassium permanganate solution with a concentration of 0.04mol / L, stir for 28 hours at a speed of 150r / min, carry out manganese doping modification, filter, and roast at a temperature of 450°C The solid product was calcined for 0.5 h, and then ground to obtain manganese-loaded waste bacterial residue biomass activated carbon for the ads...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com