Multifunctional integrated manufacturing system based on discharge machining

A manufacturing system and electric discharge machining technology, applied in the direction of electrode manufacturing, electric processing equipment, manufacturing tools, etc., can solve the problems of limited processing features, additive manufacturing functions that cannot realize the processing and manufacturing of small-sized parts, and low functional integration. Achieve the effect of high efficiency and precision processing characteristics, wide range of processing application and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

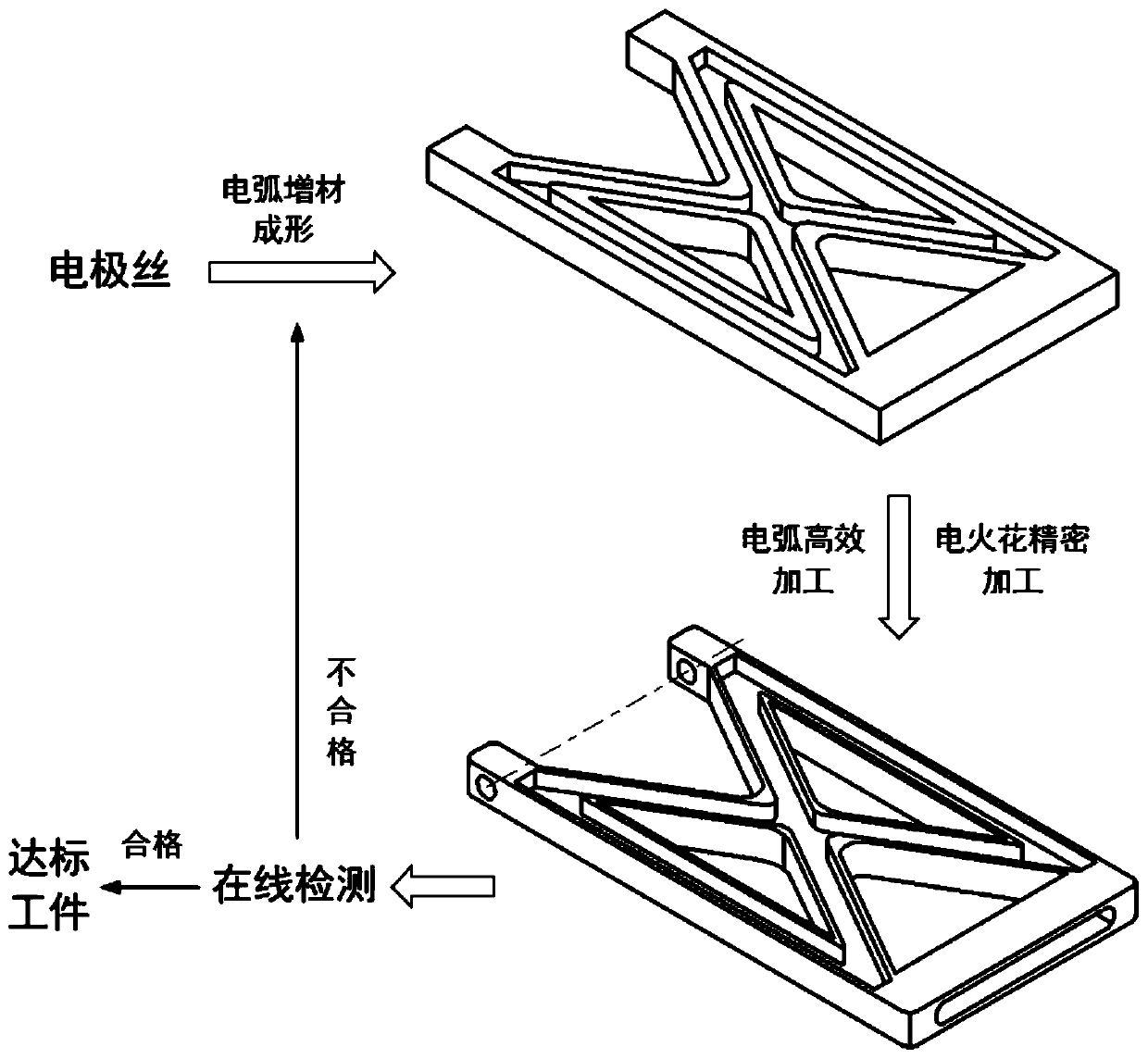

[0068] as attached image 3 The three-dimensional size of the frame parts shown is 600mm×310mm×40mm, and the material of the parts is nickel-based superalloy. The process of using the present invention to process and manufacture this part is:

[0069] ①. Set the power supply parameter output mode of the multifunctional composite discharge power supply 4 to the third gear (arc additive forming mode), set the current to 100A, and the working medium supply recovery unit 5 provides welding protection gas, and use the arc additive forming method to process Frame parts with finishing allowances;

[0070] ②. Set the power supply parameter output mode of the multifunctional composite discharge power supply 4 to gear 1 (arc high-efficiency processing mode), set the peak current to 500A, pulse width to 6ms, pulse interval to 4ms, open circuit voltage to 90V, and the working medium supply and recovery unit 5 to provide water base For the working fluid, two through holes and a square ca...

Embodiment 2

[0074] as attached Figure 4 There is a defect in the blade part shown, and the integrated manufacturing system of the present invention is used for additive manufacturing repair:

[0075] 1. Place the defective blade workpiece on the workbench 11, use the online detection function of the system of the present invention to optically scan the defect and reversely obtain the shape of the defect according to the original three-dimensional model of the workpiece;

[0076] ②. Set the power supply parameter output mode of the multifunctional composite discharge power supply 4 to gear 3 (arc additive forming mode), set the current to 100A, and supply the working medium to the recovery unit 5 to provide welding protection gas. According to the reverse obtained defect shape, Use arc additive forming to fill and repair the defect;

[0077] ③. Since the surface of arc additive forming is relatively rough, it needs to be finished. Set the power supply parameter output mode of the multif...

Embodiment 3

[0079] as attached Figure 5 The micro-electro-mechanical transmission system (MEMS) paddle part shown has a paddle shaft diameter of 0.2 mm, a height of 1.2 mm, a blade peripheral diameter of 1.6 mm, and a thickness of 0.2 mm, and the material of the parts is stainless steel. The process of using the present invention to process and manufacture this part is:

[0080] ①. Set the power supply parameter output mode of the multifunctional compound discharge power supply 4 to gear 2 (EDM precision machining mode), set the peak current to 5A, the pulse width to 10μs, the pulse interval to 20μs, the open circuit voltage to 120V, and the working medium supply recovery unit 5 to provide oil Based on the working fluid, the disc blank with a diameter of 1.8mm and a thickness of 0.2mm is subjected to EDM precision machining, and the attached image 3 blisks shown;

[0081] ②. Place the blisk processed in step ① on the workbench 11, and set the multifunctional composite discharge power ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com