Micro-electrolytic filler for realizing the resource utilization of iron mud, preparation method and use thereof

A resourceful, micro-electrolysis technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as micro-electrolysis fillers that have not been found, and achieve improved biodegradability, content removal, The effect of saving drug costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

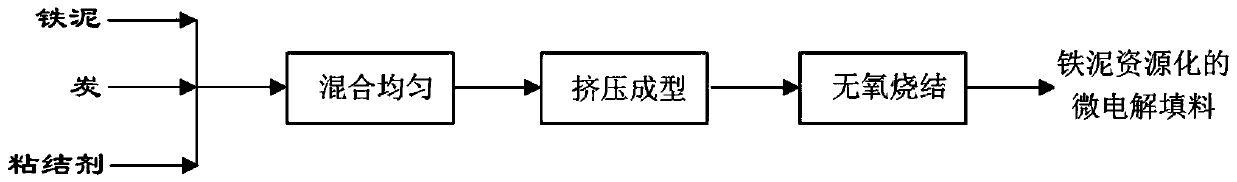

Method used

Image

Examples

Embodiment 1

[0034] First mix semi-coke, iron slime and binder evenly according to the proportion, wherein 25 parts of semi-coke, 75 parts of iron mud, 12 parts of binder, 12 parts of binder are composed of 5 parts of bentonite, 5 parts of sodium silicate and A mixture formed by 2 parts of phenolic resin, the materials are mixed evenly and aged for 4 hours; then, the aged materials are mechanically extruded to obtain a green body, and the green body is dried naturally at 120°C for 2 hours; After drying the green body at 1200 °C in N 2 Sintering under the atmosphere for 2 hours, and after cooling, the micro-electrolytic filler that realizes the resource utilization of iron slime can be obtained.

[0035] The effect of treating semi-coke wastewater with the prepared micro-electrolytic filler is as follows:

[0036] The semi-coke wastewater with a COD concentration of 6500mg / L is subjected to micro-electrolysis treatment after acid adjustment. The hydraulic retention time is 6h, the temperat...

Embodiment 2

[0038] First, mix coke, iron slime and binder evenly according to the proportion, including 45 parts of coke, 50 parts of iron slime, and 5 parts of binder, and 5 parts of binder are composed of 3 parts of sodium silicate, 1 part of phenolic resin and 1 The mixture formed by 100% tar was mixed uniformly and aged for 2 hours; then, the aged material was mechanically extruded to form a green body, and the green body was dried naturally at 90°C for 4 hours; the dried The green body is sintered in an Ar atmosphere at 850°C for 6 hours, and after cooling, the micro-electrolytic filler that realizes the recycling of iron slime can be obtained.

[0039] The effect of treating gasification wastewater with the prepared micro-electrolytic filler is as follows:

[0040] The gasification wastewater with a COD concentration of 5000mg / L is treated with micro-electrolysis after acid adjustment. The hydraulic retention time is 4h, the temperature is 40°C, and the COD removal rate reaches 38%....

Embodiment 3

[0042] First, mix the activated carbon, iron slime and binder evenly according to the proportion, including 30 parts of activated carbon, 60 parts of iron slime, 15 parts of binder, and 15 parts of binder are composed of 10 parts of bentonite, 2 parts of phenolic resin and 3 parts of starch The formed mixture was mixed uniformly and aged for 3 hours; then, the aged material was mechanically extruded to form a green body, and the green body was dried naturally at 70°C for 6 hours; the dried green body Water vapor containing N at 1100°C 2 Sintering under the atmosphere for 4 hours, and after cooling, the micro-electrolytic filler that realizes the resource utilization of iron slime can be obtained.

[0043] The effect of treating coking wastewater with the prepared micro-electrolytic filler is as follows:

[0044] The coking wastewater with a COD concentration of 3500mg / L was treated by micro-electrolysis after acid adjustment. The hydraulic retention time was 3h, the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com