Hexavalent chromium free environmentally friendly type paint for steel plates and preparation method thereof

A hexavalent chromium, environmentally friendly technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of moisture absorption, heat resistance, corrosion resistance and poor tension, and achieve industrialized production and use, low pollution, good quality Effects of stability and coatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

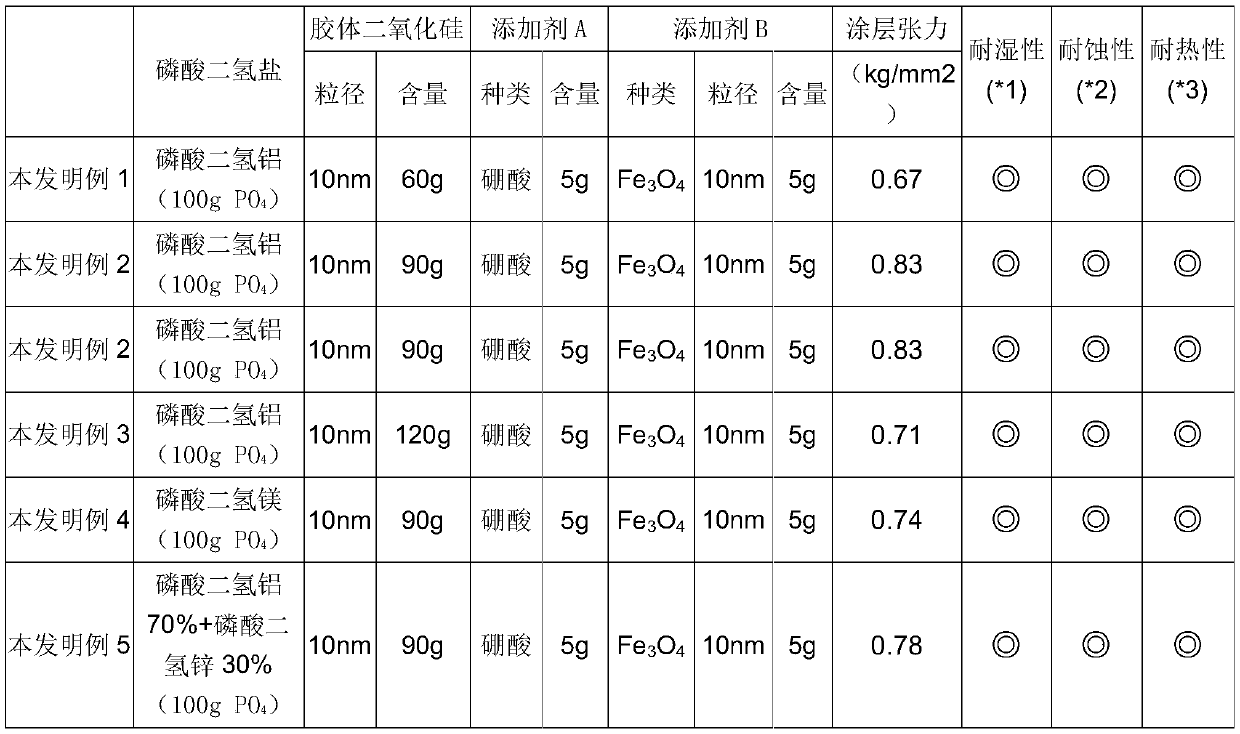

Embodiment 1

[0036] Use a high magnetic induction oriented electrical steel sheet with a thickness of 0.23mm and a bottom layer of glass film, after shearing, in 3%H 2 SO 4 After light pickling in aqueous solution at 80-85°C for 10s, it is ready for use. Add at least one of boron oxide, boric acid and magnesium borate (referred to as additive A) to the silica sol, and then add Fe 3 o 4 , V 2 o 3 、 Cr 2 o 3 and Mo 2 o 3 At least one of the powders (referred to as additive B) is stirred and ultrasonically dispersed to form a stable suspension, and then mixed with phosphate and stirred to form a coating. Relative to 100g of phosphate in the phosphate, the content of the coating components is shown in the table 1. Apply the paint on the surface of the steel plate by roller coating, then dry it and perform a sintering heat treatment at 850°C×30s. The weight of one side of the coating after sintering is 5.0g / m 2 . The results of the performance investigation of the coatings are summar...

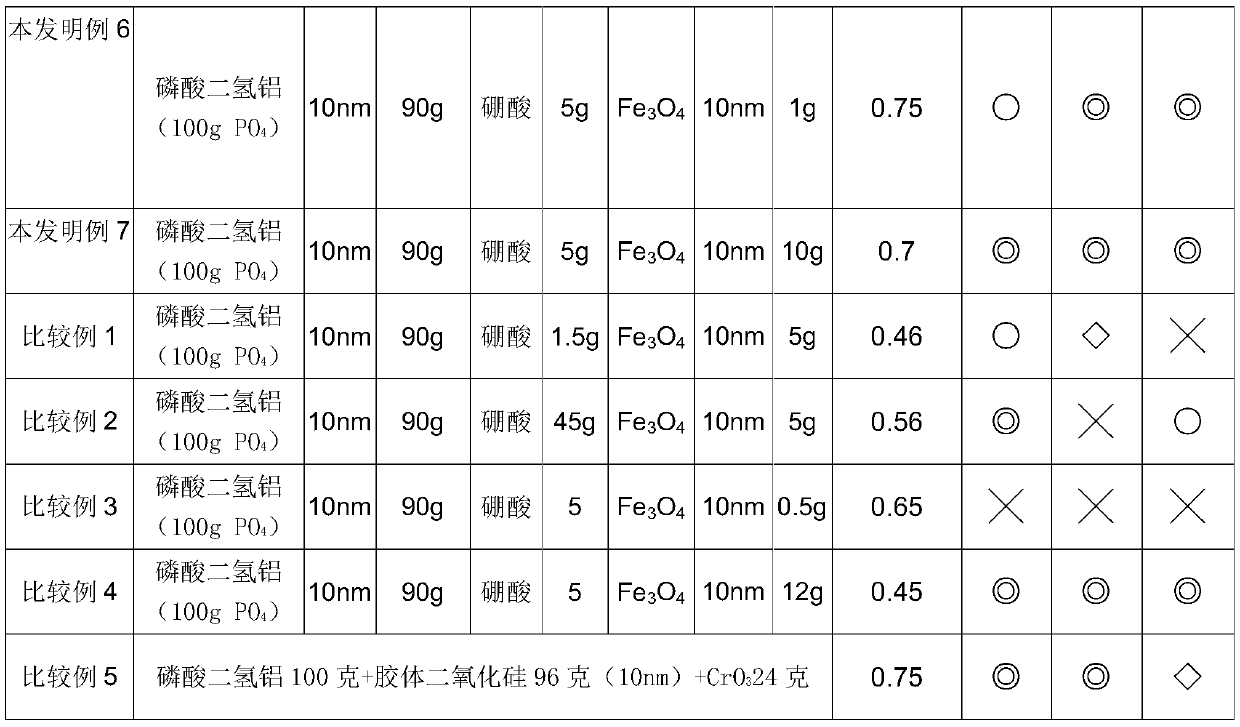

Embodiment 2

[0046] Use a high magnetic induction oriented electrical steel sheet with a thickness of 0.23mm and a bottom layer of glass film, after shearing, in 3%H 2 SO 4 After light pickling in aqueous solution at 80-85°C for 10s, it is ready for use. Add 5g of a boron compound of boron oxide, boric acid or magnesium borate (referred to as additive A) to 90g of silica sol with a particle size of 10nm, and then add 5g of Fe 3 o 4 , V 2 o 3 、Cr 2 o 3 and Mo 2 o 3 An additive in the powder, stirred and ultrasonically dispersed to form a stable suspension, then mixed with magnesium dihydrogen phosphate and stirred to form a coating, the coating contains 100g of phosphate, and the coating components are shown in Table 2. Apply the paint on the surface of the steel plate by roller coating, then dry it and perform a sintering heat treatment at 850°C×30s. The weight of one side of the coating after sintering is 5.0g / m 2 . The results of the performance investigation of the coatings ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com