Double-sided hot-melt adhesive tape and preparation method thereof

A hot-melt tape, double-sided technology, applied in the direction of adhesives, heat-activated films/sheets, adhesive types, etc., can solve the problems of reduced bonding strength, easy heat conduction, etc., and achieve fast curing speed, high curing strength, The effect of high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

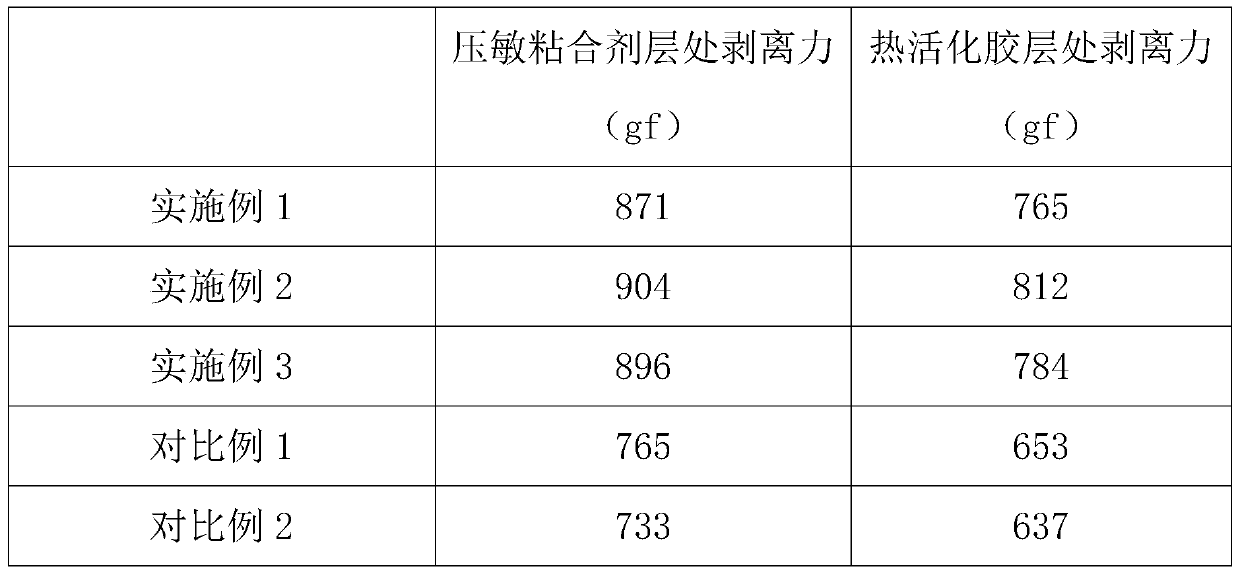

Embodiment 1

[0031] A double-sided hot-melt adhesive tape, comprising a first release paper layer, a pressure-sensitive adhesive layer, a heat-insulating base material layer, a heat-activated adhesive layer and a second release paper layer laminated in sequence, the pressure-sensitive adhesive The mixture layer is composed of the following raw materials in parts by weight: 70 parts of 2-ethylhexyl acrylate, 60 parts of dodecyl acrylate, 30 parts of methyl methacrylate, 42 parts of filler, benzoyl diphenyl 15 parts of phosphine, 8 parts of solubilizer;

[0032] The heat-insulating substrate layer is composed of the following raw materials in parts by weight: 55 parts of polyethylene terephthalate, 13 parts of boron carbide, 12 parts of silicon phosphide, and 11 parts of nano-tin oxide;

[0033] The heat-activated adhesive layer is composed of the following raw materials in parts by weight: 80 parts of aromatic polyester polyurethane, 55 parts of polymer polyester resin, 15 parts of activate...

Embodiment 2

[0050] A double-sided hot-melt adhesive tape, comprising a first release paper layer, a pressure-sensitive adhesive layer, a heat-insulating base material layer, a heat-activated adhesive layer and a second release paper layer laminated in sequence, the pressure-sensitive adhesive The mixture layer is composed of the following raw materials in parts by weight: 95 parts of 2-ethylhexyl acrylate, 75 parts of dodecyl acrylate, 35 parts of methyl methacrylate, 50 parts of filler, benzoyl diphenyl 20 parts of phosphine, 11 parts of solubilizer;

[0051] The heat-insulating substrate layer is composed of the following raw materials in parts by weight: 55 parts of polyethylene terephthalate, 15 parts of boron carbide, 14 parts of silicon phosphide, and 13 parts of nano-tin oxide;

[0052] The heat-activated adhesive layer is composed of the following raw materials in parts by weight: 90 parts of aromatic polyester polyurethane, 65 parts of polymer polyester resin, 17 parts of activat...

Embodiment 3

[0069] A double-sided hot-melt adhesive tape, comprising a first release paper layer, a pressure-sensitive adhesive layer, a heat-insulating base material layer, a heat-activated adhesive layer and a second release paper layer laminated in sequence, the pressure-sensitive adhesive The mixture layer is composed of the following raw materials in parts by weight: 120 parts of 2-ethylhexyl acrylate, 90 parts of dodecyl acrylate, 40 parts of methyl methacrylate, 58 parts of filler, benzoyl diphenyl 25 parts of phosphine, 14 parts of solubilizer;

[0070] The heat-insulating substrate layer is composed of the following raw materials in parts by weight: 75 parts of polyethylene terephthalate, 17 parts of boron carbide, 16 parts of silicon phosphide, and 15 parts of nano-tin oxide;

[0071] The heat-activated adhesive layer is composed of the following raw materials in parts by weight: 100 parts of aromatic polyester polyurethane, 75 parts of polymer polyester resin, 18 parts of activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com