Solvent-based polyurethane hot-melt adhesive material, preparation method and application method thereof

A polyurethane hot-melt adhesive, solvent-based technology, used in polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of poor transportation stability, high bonding strength, environmental hazards, etc. Strong, high solid content, fast crystallization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

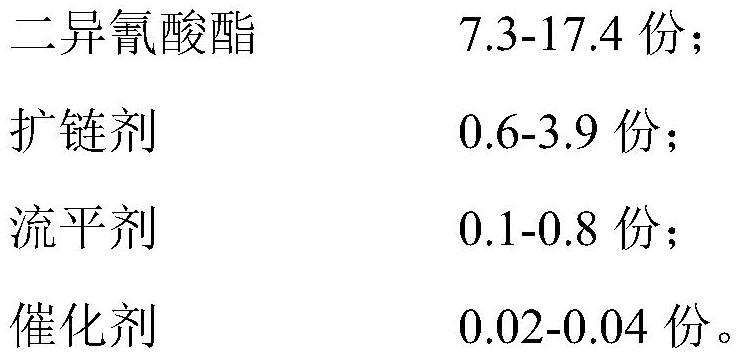

Method used

Image

Examples

Embodiment 1

[0026] With a mass part, 79.33 parts of polycaparidate glycol (PEA, M = 2000), 0.4 parts of S3207, 0.4 parts B333, 0.04 parts of the tin catalyst T-9, and the reactor tin catalyst T-9 was added. The maintenance temperature was 95 ° C; 16.96 parts of MDI-100 were added to the reaction kettle B, and the temperature was 75 ° C; 1.72 parts of 1,4-butanediol, 1.15 parts of 1,6-hexanediol were added to the reactor C, The maintenance temperature is 60 ° C; the isocyanate index is controlled at 1.01. The temperature of each reactor is stable, by mixing the reactor A, the reactor B and the raw material components in the reaction kettle A, the reaction kettle B and the reactor c, injects the twin screw extruder, mixed materials The double-screw in vivo is uniformly reactive, and after plasticizing, it is squeezed into an elliptical particles having a uniform particle size, i.e., a solvent-type polyurethane hot melt adhesive material.

Embodiment 2

[0028] With mass parts, 85.74 parts of polyciparate butnesate diol (PBA, M = 3000), 0.5 parts of B310, 0.03 parts of the tin catalyst T-9 were added to the reaction kettle A, and the temperature was 100%. EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc (EtOAc) ° C; isocyanate index is controlled at 0.99. The temperature of each reactor is stable, by mixing the reactor A, the reactor B and the raw material components in the reaction kettle A, the reaction kettle B and the reactor c, injects the twin screw extruder, mixed materials The double-screw in vivo is uniformly reactive, and after plasticizing, it is squeezed into an elliptical particles having a uniform particle size, i.e., a solvent-type polyurethane hot melt adhesive material.

Embodiment 3

[0030] 48.83 parts of polyciparate dikanol (Pba, M = 4000), 42.6 polycaprolactone diol (PCl, M = 2000), 0.6 parts of B333, 0.03 parts of organic Tin catalyst T-9, adding the reaction kettle A, maintaining the temperature of 105 ° C; 7.32 parts of MDI-100 was added to the reaction kettle B, and the temperature was 60 ° C; 0.54 parts of 1,4-butanediol, 0.09 parts 1 The 6-hexidol was added to the reactor C, the temperature was 40 ° C; the isocyanate index was controlled at 1.03. The temperature of each reactor is stable, by mixing the reactor A, the reactor B and the raw material components in the reaction kettle A, the reaction kettle B and the reactor c, injects the twin screw extruder, mixed materials The double-screw in vivo is uniformly reactive, and after plasticizing, it is squeezed into an elliptical particles having a uniform particle size, i.e., a solvent-type polyurethane hot melt adhesive material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com