Fluoropolymers and antirust agents using them as active ingredients

A technology of active ingredients and anti-rust agents, applied in anti-corrosion coatings, other chemical processes, coatings, etc., to achieve effective anti-rust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

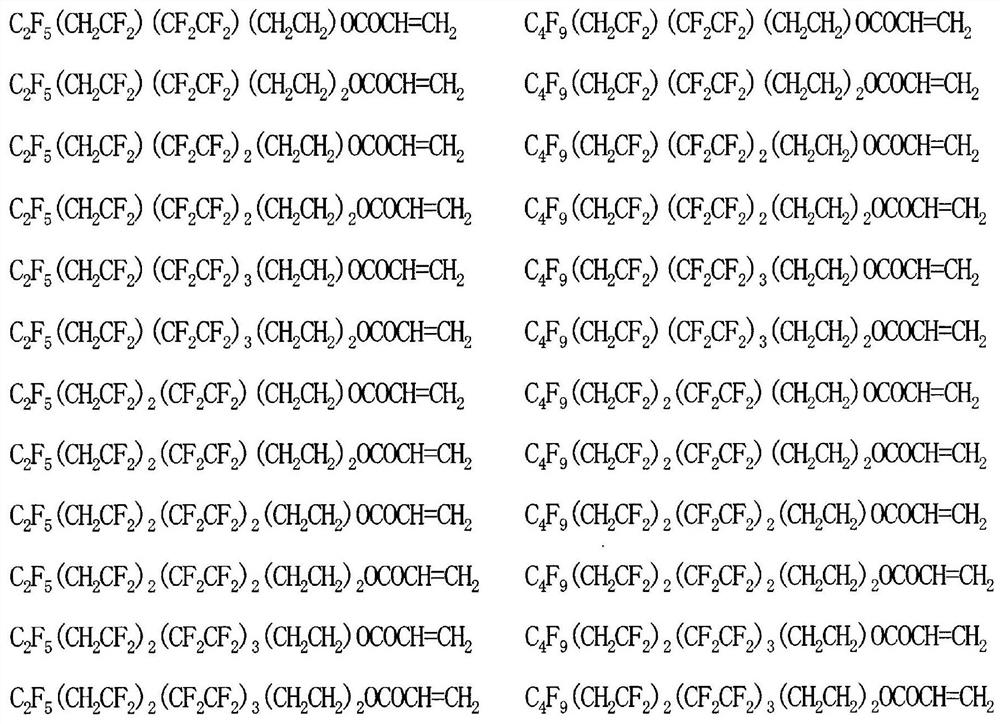

Method used

Image

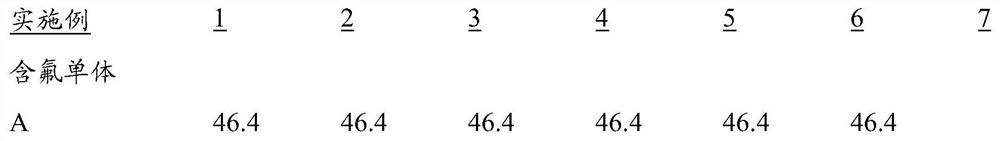

Examples

Embodiment

[0102] The present invention is described below with reference to examples.

Synthetic example 1

[0104] (1) In a 1200mL autoclave equipped with a stirrer and a thermometer, add 529 grams (0.86mol) of CF 3 (CF 2 ) 3 (CH 2 CF 2 )(CF 2 CF 2 ) 2 I (99.9 GC%) and 5 g of di-tert-butyl peroxide, and the autoclave was degassed with a vacuum pump. When the internal temperature rose to 80° C., ethylene was successively introduced into the autoclave to adjust the internal pressure to 0.5 MPa. When the internal pressure dropped to 0.2 MPa, ethylene was introduced again to increase the internal pressure to 0.5 MPa. This operation was repeated to introduce 34 g (1.2 mol) of ethylene in about 3 h while maintaining the internal temperature at 80-115°C. The contents were collected at an internal temperature below 50 °C to give 550 g (yield: 99.4%) of CF 3 (CF 2 ) 3 (CH 2 CF 2 )(CF 2 CF 2 ) 2 (CH 2 CH 2 ) I (99.1 GC%).

[0105] (2) In a 200mL three-necked flask equipped with a condenser and a thermometer, add 150 grams (0.24mol) of CF prepared in (1) above 3 (CF 2 ) 3...

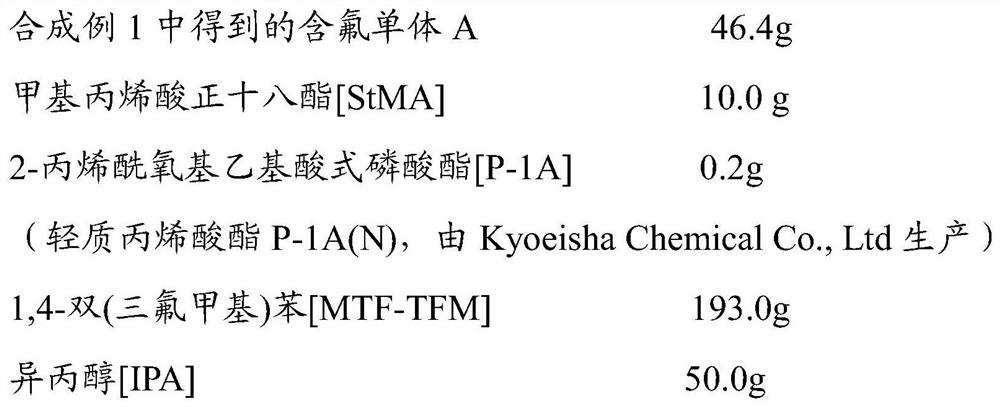

Synthetic example 2

[0114]60.0g (0.11mol) of the reaction product (95.4GC%), 29g of toluene, 1.6g of p-toluenesulfonic acid and 0.07g of hydroquinone prepared in (2) of Synthesis Example 1 were added to a 100mL three-necked tube equipped with a condenser and a thermometer in the flask. After the internal temperature rose to 100°C, 12 g (0.14 mol) of methacrylic acid was added to the flask, followed by stirring at an internal temperature of 118°C for 3 hours. After the reaction was completed, it was cooled, and then 82 g of the reaction solution was collected. Toluene was removed with an evaporator, and 64 g of the residue was washed with tap water to obtain 60.8 g (yield: 86%) of a reaction product (89 GC%) that was a colorless transparent liquid at room temperature as a lower layer.

[0115] The reaction product was distilled under reduced pressure at an internal pressure of 0.2 kPa, an internal temperature of 125 to 155° C. and a tower top temperature of 84 to 86° C. to obtain 42.2 g (distilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com