Long-acting anti-rust oil composition for bearing parts and preparation method thereof

A technology of anti-rust oil and composition, which is applied in the field of long-term anti-rust oil composition and its preparation for bearing parts, and can solve the problems of poor thermal stability of anti-rust oil, difficulty in protecting bearing parts, general salt spray resistance, etc. , to achieve effective anti-rust performance, improve thermal stability and salt spray resistance, scientific and reasonable formula effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

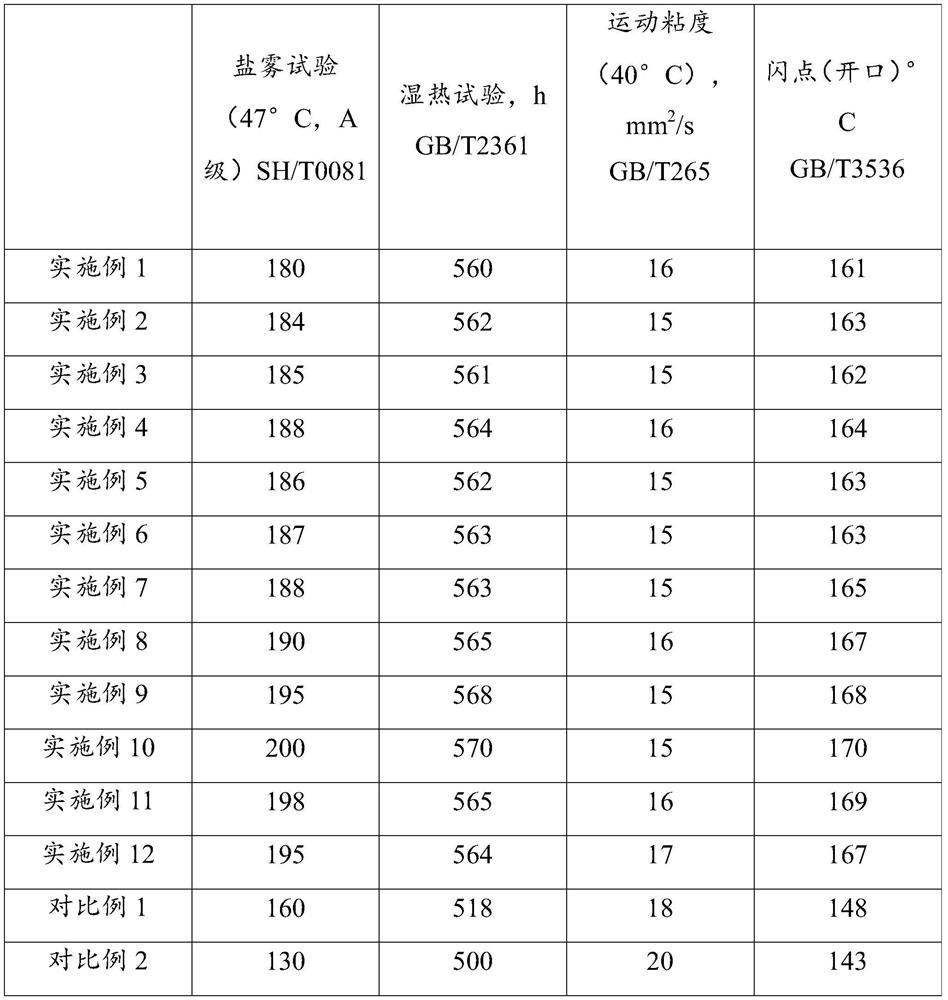

Examples

Embodiment 1

[0025] The mass percentages of each component of the modified film-forming agent are as follows: acrylic resin film-forming agent: 40%, modifier: 4%, polyoxypropylene ether: 0.4%, deionized water: 55.6%; It is novolac epoxy vinyl ester resin;

[0026] Preparation of modified film-forming agent: first put the modifier and deionized water into the reaction kettle, heat under high pressure to 120°C under 2MPa, and then stir and mix for 10 minutes to obtain the mixed solution A, then in the mixed solution Add an acrylic resin film-forming agent to A, continue stirring and mixing, and stir for 20 minutes to obtain a mixed solution B, then add polyoxypropylene ether to the mixed solution B, continue stirring, and obtain a modified film-forming agent after mixing evenly;

[0027] Put 60 parts of base oil, 20 parts of aromatic oil, 0.6 part of benzotriazole, 0.4 part of polyoxyethylene ether and 0.4 part of sodium alkylbenzene sulfonate into a reaction kettle for heating until the tem...

Embodiment 2

[0029] The mass percentages of each component of the modified film-forming agent are as follows: acrylic resin film-forming agent: 50%, modifier: 4%, polyoxypropylene ether: 0.6%, deionized water: 45.4%; It is novolac epoxy vinyl ester resin;

[0030] Preparation of modified film-forming agent: first put the modifier and deionized water into the reaction kettle, heat under high pressure to 130°C under 3MPa, and then stir and mix for 15 minutes to obtain the mixed solution A, then in the mixed solution Add an acrylic resin film-forming agent to A, continue stirring and mixing, and stir for 30 minutes to obtain a mixed solution B, then add polyoxypropylene ether to the mixed solution B, continue stirring, and obtain a modified film-forming agent after mixing evenly;

[0031] Put 60 parts of base oil, 20 parts of aromatic oil, 0.6 part of benzotriazole, 0.4 part of polyoxyethylene ether and 0.4 part of sodium alkylbenzene sulfonate into a reaction kettle for heating until the tem...

Embodiment 3

[0033] The mass percentages of each component of the modified film-forming agent are as follows: acrylic resin film-forming agent: 50%, modifier: 4%, polyoxypropylene ether: 0.6%, deionized water: 45.4%; It is novolac epoxy vinyl ester resin;

[0034] Preparation of modified film-forming agent: first put the modifier and deionized water into the reaction kettle, heat under high pressure to 130°C under 3MPa, and then stir and mix for 15 minutes to obtain the mixed solution A, then in the mixed solution Add an acrylic resin film-forming agent to A, continue stirring and mixing, and stir for 30 minutes to obtain a mixed solution B, then add polyoxypropylene ether to the mixed solution B, continue stirring, and obtain a modified film-forming agent after mixing evenly;

[0035]Put 80 parts of base oil, 40 parts of aromatic oil, 0.8 part of benzotriazole, 0.6 part of polyoxyethylene ether and 0.6 part of sodium alkylbenzene sulfonate into a reaction kettle for heating until the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com