Two-layer composite periodontal defect repair material based on photo-crosslinking hydrogel and preparing method of material

A double-layer composite and repair material technology, applied in medical science, prosthesis, etc., can solve the problems of single composition, structure and function, complicated operation and use, complicated preparation process, etc., and achieve good biocompatibility, excellent mechanical Performance and stability, the effect of high hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Preparation of GelMA: Weigh 10.0 g of pigskin collagen with a balance, add it to 100 mL of deionized water, heat to 60°C, and stir until the collagen is completely dissolved. Add 8 mL of methacrylate solution (methacrylicanhydride, MA) to the above collagen solution at a flow rate of 0.5 mL / min and a temperature of 80° C., stir, and let stand for 3 hours after all the MA solution is added dropwise. Subsequently, 500 mL of deionized water was added, stirred for 30 minutes, and then packed in a dialysis bag with a molecular weight of 12,000. Place the subpackaged dialysis bags in deionized water, magnetically stir, and dialyze; replace the deionized water every 24 hours for 7 days. The dialyzed GelMA solution was filtered, placed in a large Petri dish, covered with a parafilm, and kept overnight at -80°C. Finally, the pre-frozen GelMA solution was placed in a low-temperature freeze dryer, freeze-dried for 5 days, and the samples were taken out and stored in the dark.

Embodiment 2

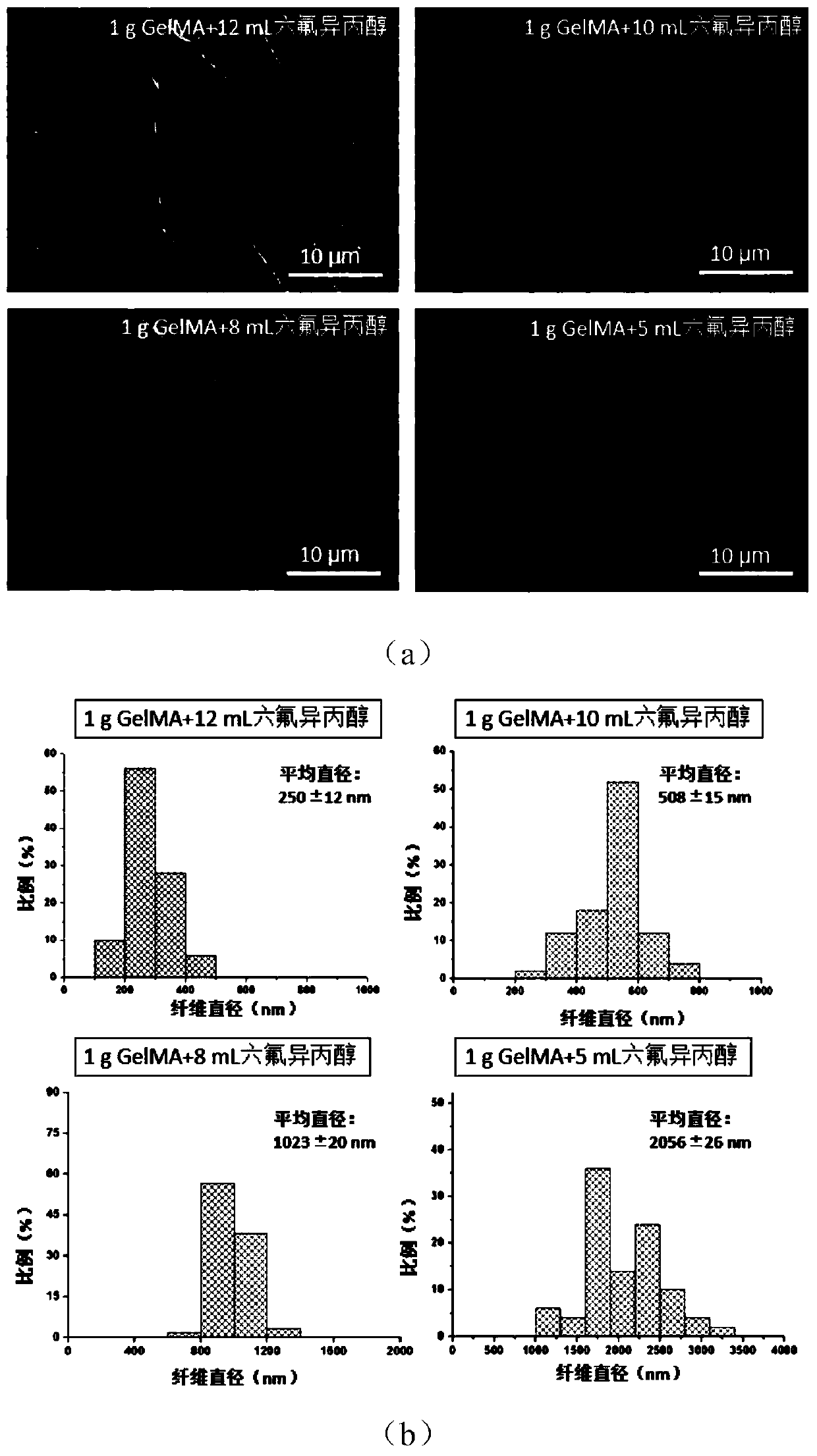

[0039] Preparation of GelMA electrospun fibers: Weigh 1g of GelMA with a balance, add 5mL, 8mL, 10mL, and 12mL of hexafluoroisopropanol solution, shake until the GelMA is completely dissolved, and obtain different concentrations of GelMA / hexafluoroisopropanol solutions. Take a certain concentration of the above solution into a 5mL syringe, and fix the syringe to the syringe pump of the electrospinning machine. Cut a 30cm x 30cm rectangular piece of aluminum foil and wrap it around the receiver. The distance between the needle of the syringe and the foil is 10cm. The needle is connected to the positive electrode, the aluminum foil is connected to the negative electrode, the voltage of the spinning machine is set to 22kv, and the driving speed of the syringe pump is 0.0015mm / s. After electrospinning until all the GelMA solution was exhausted, the spun GelMA fiber membrane was removed from the electrospinning machine and left at room temperature for 24 hours to evaporate all the ...

Embodiment 3

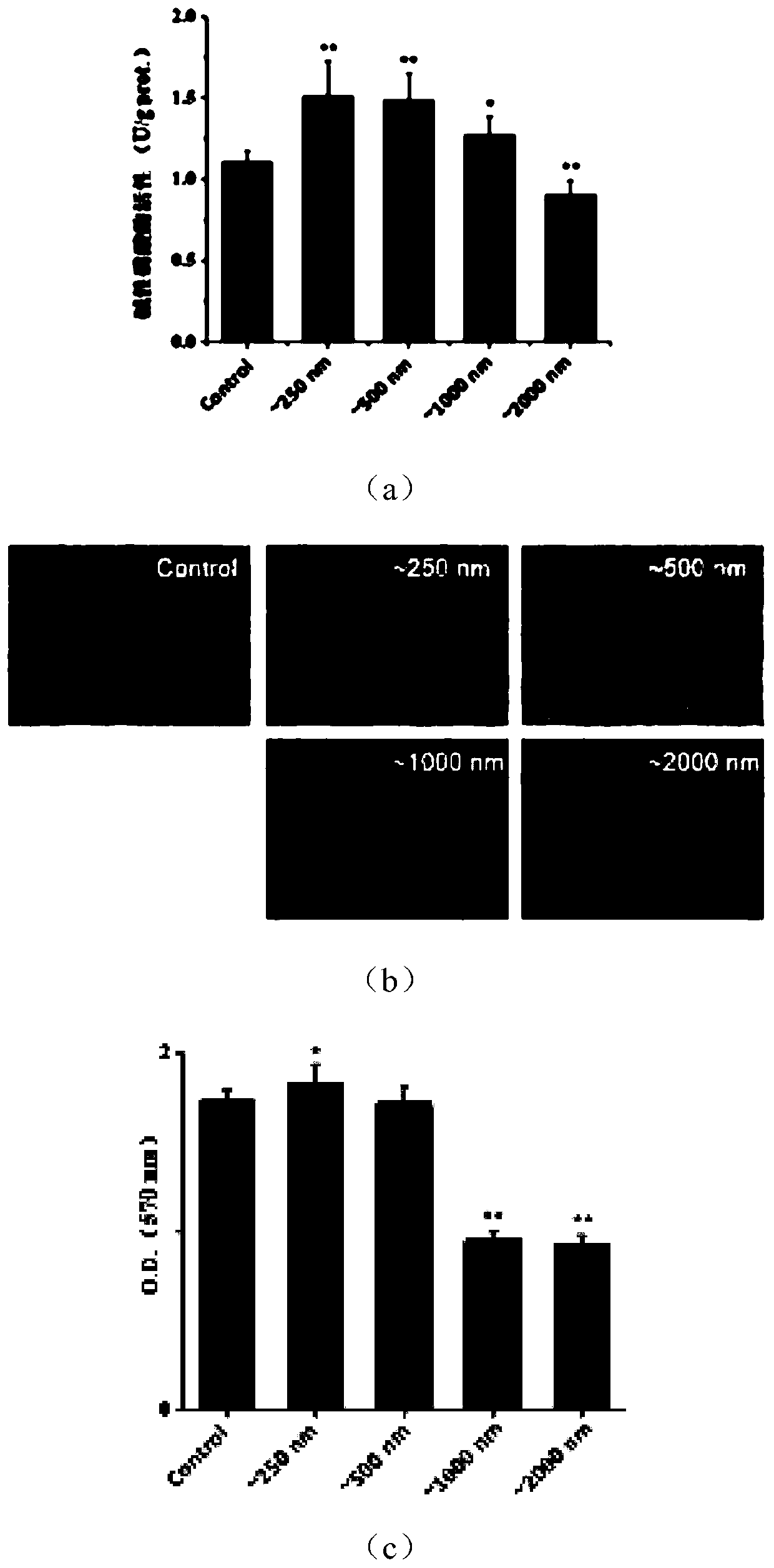

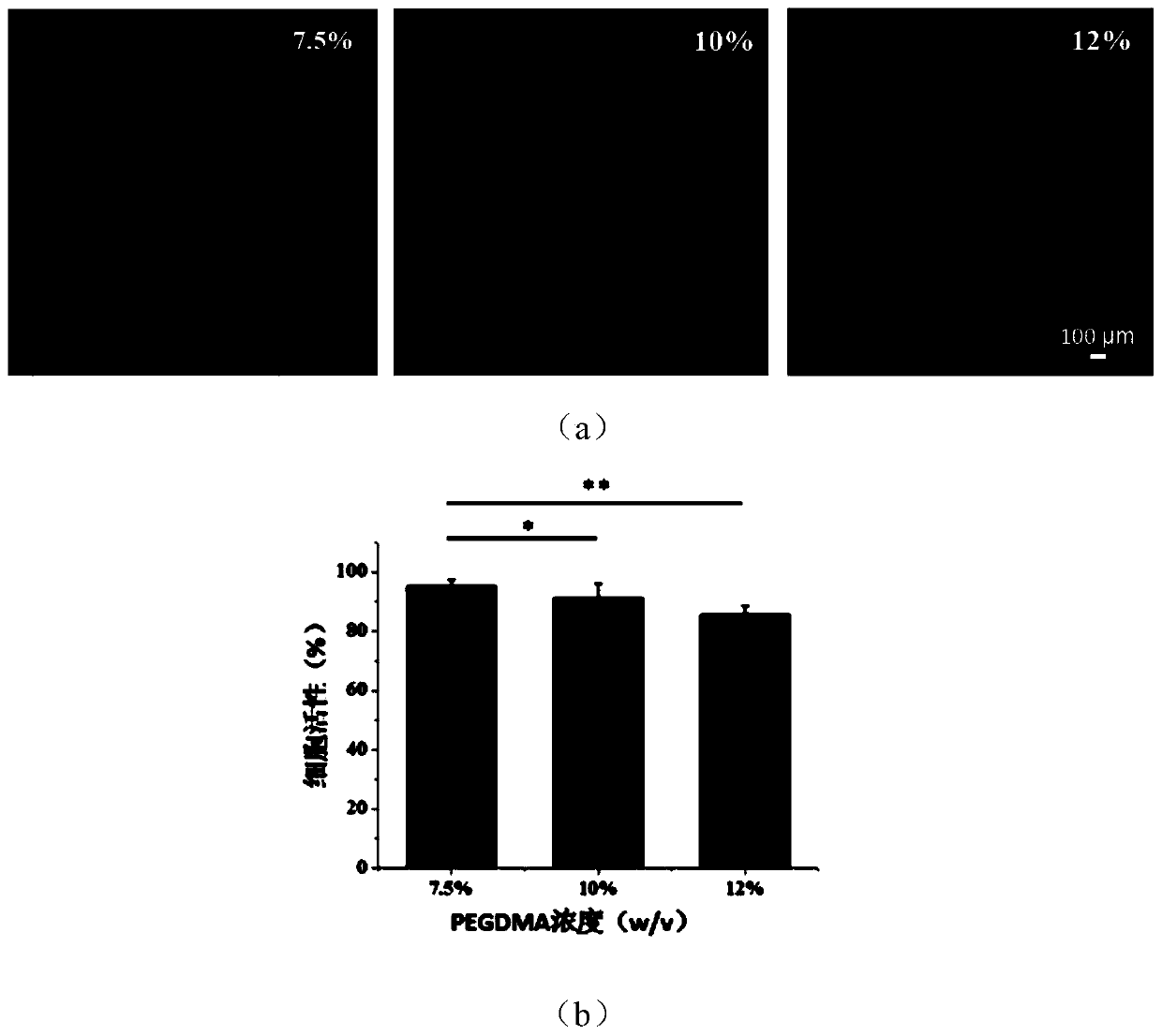

[0042] Preparation of GelMA fiber hydrogel membrane: The GelMA electrospun fibers with different fiber diameters prepared in Example 2 were cut into square samples (size: 1 cm*1 cm). Mix 10 mL of absolute ethanol with 1 mL of dihydroxydimethylpropiophenone solution and place on a shaker for 10 minutes to obtain a cross-linking liquid. Take 0.1ml of cross-linking solution and add it dropwise to each GelMA electrospun fiber sample in turn, and light it for 90s with a point-type cross-linking instrument (OmniCure, Canada) at a light intensity of 2.9mW / cm 2 , with a distance of 1 cm to prepare the GelMA fiber hydrogel membrane. In order to remove the residual cross-linking agent, the cross-linked samples were soaked in absolute ethanol for 5 h, and then used.

[0043] Periodontal ligament stem cells were sequentially seeded on GelMA fiber hydrogel membranes with different fiber diameters (cell density: 10 6 per well), using osteogenic induction medium (containing 10mM β-glycerop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com