A kind of phosphorus removal adsorbent and preparation method thereof

A phosphorus adsorbent, phosphate ion technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of insufficient strength of ordinary adsorbents, poor adsorption effect, low economic cost, etc. Achieve the effect of realizing a virtuous cycle, simple and stable preparation method, and low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

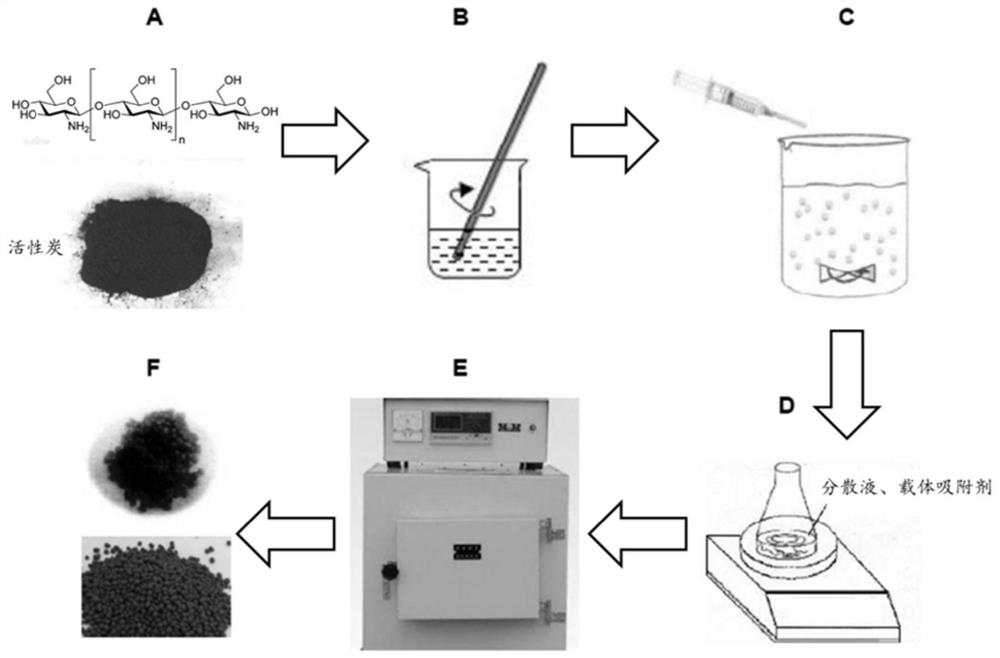

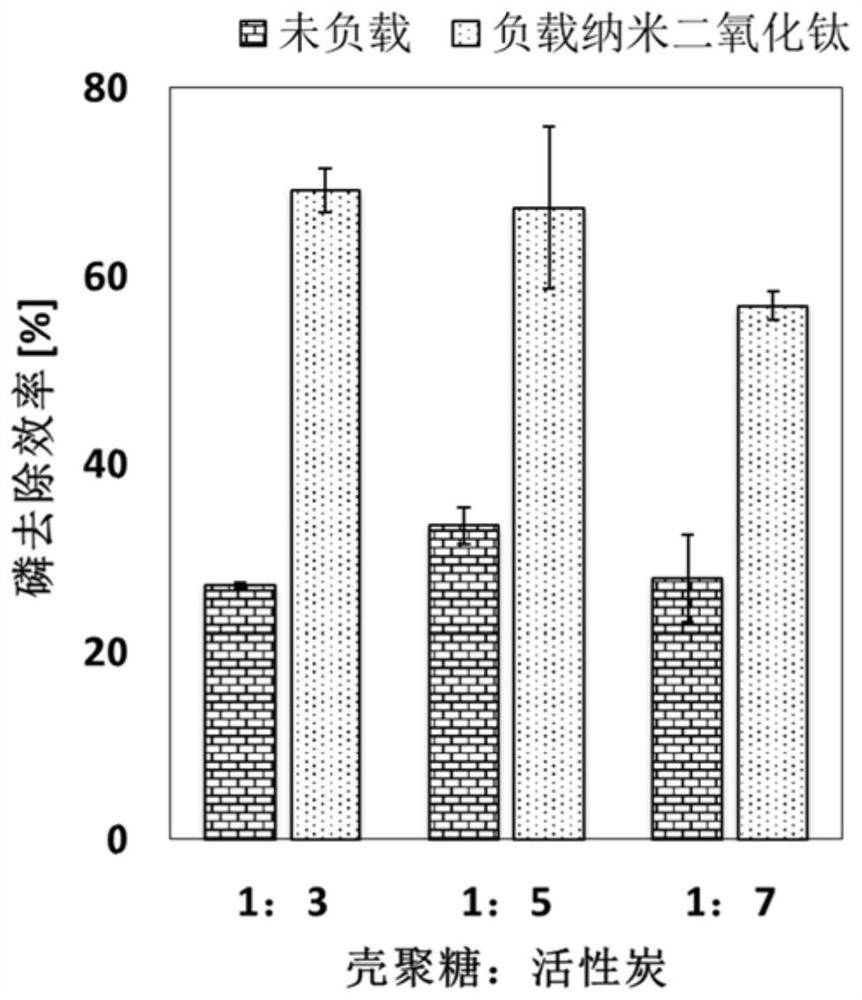

[0035] (1) if figure 1 As shown in A and 1B, weigh 3g of the mixture of chitosan and activated carbon with a mass ratio of 1:3, and add it to the acetic acid solution with a mass concentration of 1.2%, to obtain a thick mixed solution;

[0036] (2) Mix sodium hydroxide solution with a mass concentration of 40% and absolute ethanol at a volume ratio of 1:10 to obtain an alkaline stationary solution;

[0037] (3) if figure 1 As shown in C, add the mixed solution dropwise to 80mL of fixative solution to obtain pellets, wash the pellets with distilled water until neutral, and dry to obtain the carrier adsorbent;

[0038] (4) if figure 1 Shown in D, nano-titanium dioxide and sodium dodecylbenzenesulfonate are added in water to obtain a dispersion, the mass concentration of nano-titanium dioxide in the dispersion is 1%, and the concentration of sodium dodecylbenzenesulfonate is 0.017mol / L, Add the carrier adsorbent to the dispersion, heat in a water bath at 60°C, and maintain mag...

Embodiment 2

[0041] (1) Take by weighing 3g mass ratio of chitosan and activated carbon mixture of 1:5, join in the acetic acid solution whose mass concentration is 1.2%, obtain the thick mixed solution;

[0042] (2) Mix sodium hydroxide solution with a mass concentration of 40% and absolute ethanol at a volume ratio of 1:15 to obtain an alkaline stationary solution;

[0043] (3) Add the mixed solution dropwise to 100 mL of fixative solution to obtain pellets, wash the pellets with distilled water until neutral, and dry to obtain the carrier adsorbent;

[0044] (4) adding nano-titanium dioxide and sodium dodecylbenzenesulfonate into water to obtain a dispersion, the mass concentration of nano-titanium dioxide in the dispersion is 2%, and the concentration of sodium dodecylbenzenesulfonate is 0.03mol / L. The carrier adsorbent is added to the dispersion liquid, heated in a water bath at 50°C, and kept under magnetic stirring for 12 hours, with the magnet rotating at 350rpm;

[0045] (5) Filt...

Embodiment 3

[0047] (1) Take 3g of chitosan and activated carbon mixture with a mass ratio of 1:7, and add it to the 1.2% acetic acid solution to obtain a thick mixed solution;

[0048] (2) Mix sodium hydroxide solution with a mass concentration of 40% and absolute ethanol at a volume ratio of 1:20 to obtain an alkaline stationary solution;

[0049] (3) Add the mixed solution dropwise to 110 mL of fixative to obtain pellets, wash the pellets with distilled water until neutral, and dry to obtain the carrier adsorbent;

[0050] (4) adding nano-titanium dioxide and sodium dodecylbenzenesulfonate into water to obtain a dispersion, the mass concentration of nano-titanium dioxide in the dispersion is 1.5%, and the concentration of sodium dodecylbenzenesulfonate is 0.01mol / L. The carrier adsorbent is added to the dispersion liquid, heated in a water bath at 70°C, and maintained for 36 hours under magnetic stirring, with the magnet rotating at 400rpm;

[0051] (5) Filtrate after stirring, wash with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com