Preparation method of amphipathic catalyst TS-1@AOF

A TS-1, catalyst technology, applied in the field of petroleum additives, can solve the problems of complex process, high cost, harsh conditions, etc., and achieve the effect of simple process and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Preparation of Amphiphilic Catalyst TS-1@AOF

[0036] This example provides a specific method for preparing the amphiphilic catalyst TS-1@AOF, comprising the following steps:

[0037] 1) Synthesis of titanium silicate molecular sieve TS-1

[0038] After mixing 8ml of TPAOH, 5ml of TEOS and 5ml of secondary water, stir at room temperature for 24 hours to form solution A; add 0.2mL of TBOT to 10.0mL of 30% H 2 o 2 , solution B was formed.

[0039]Solution B was added dropwise to solution A and stirred at room temperature for 24 hours to form a transparent sol. The formed transparent sol was put into a stainless steel kettle, stood at 100 degrees Celsius for 24 hours, stood at room temperature, centrifuged, washed twice with water, and washed once with alcohol. Calcined at 550°C for 6 hours to remove template TPA + .

[0040] 2) Synthesis of vinyl-modified TS-1

[0041] 0.10g TS-1 nanoparticles were sonicated in 50ml 0.1M HCl for 10 minutes, centrifuged, w...

Embodiment 2

[0046] Embodiment 2 catalytic activity verification

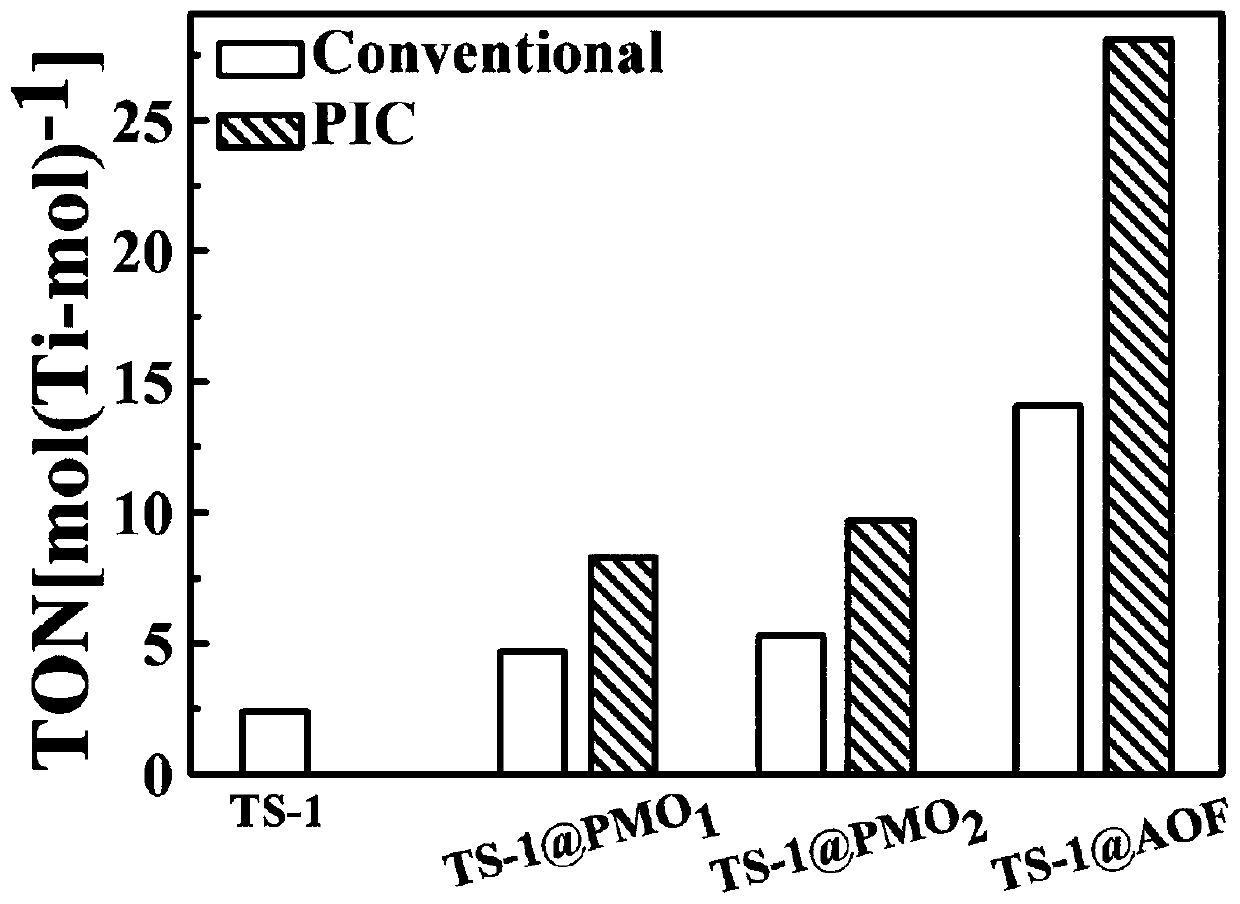

[0047] To demonstrate the superiority of the TS-1@AOF material, we conducted a control experiment. The comparative catalytic material is TS-1@PMO 1 and TS-1@PMO 2 Two kinds of nanoparticles with yolk-shell structure. PMO 1 The shell was prepared by hydrolysis and polymerization of the non-amphiphilic organosilane precursor BTOSVB, while PMO 2 The shell is prepared by hydrolysis and polymerization of the non-amphiphilic organosilane precursor BTEB. TS-1@PMO 1 and TS-1@PMO 2 The specific catalytic experimental process of the two egg yolk-shell nanoparticles is consistent with the traditional catalytic process of the Pickering catalytic process of TS-1@AOF amphiphilic solid nanoparticles.

[0048] Pickering catalytic process: 50mg of TS-1@AOF amphiphilic solid nanoparticles were added to 1.5ml of hydrogen peroxide solution (30wt%) and 1.5ml of 1-hexene, and sonicated for 15 minutes. At a temperature of 333K, let stand ...

Embodiment 3

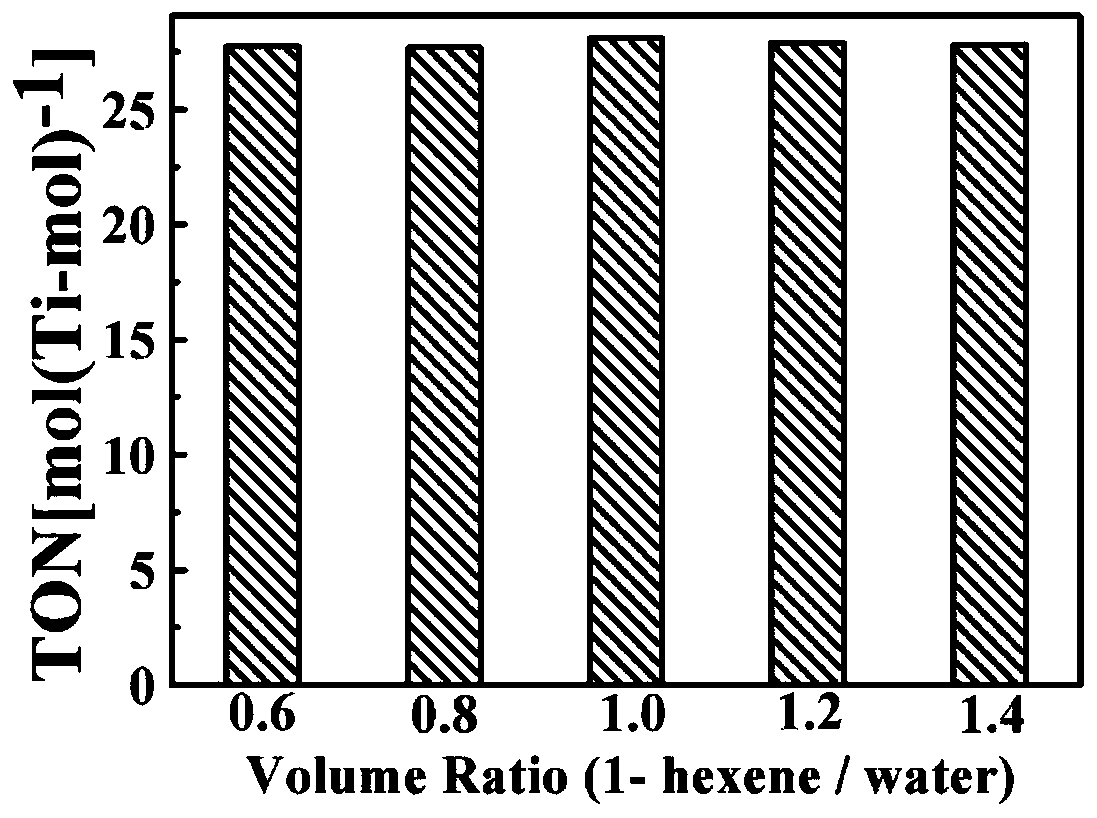

[0052] Embodiment 3 catalytic scope

[0053] 50 mg of TS-1@AOF amphiphilic solid nanoparticles were added to solutions with 1-hexene / water ratios of 0.6, 0.8, 1.0, 1.2, and 1.4, and sonicated for 15 minutes. At a temperature of 333K, let stand to react for 1h.

[0054] The result is as figure 2 As shown, when the ratio of 1-hexene / water is 0.6, 0.8, 1.0, 1.2 and 1.4, their TON values are 27.75, 27.7, 28.1, 27.9 and 27.8, respectively. It shows that the prepared amphiphilic TS-1@AOF nanoparticles are not only suitable for the 1-hexene / water ratio of 1:1, but also suitable for the catalytic reaction of other ratios of 1-hexene / water. And the TON value does not change much. TS-1@AOF has a wide range of applications, all of which can be attributed to the good amphiphilicity of the amphiphilic silicone skeleton AOF shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com