Ultralow-content noble metal composite catalyst for acetylene hydrochlorination reaction and preparation method thereof

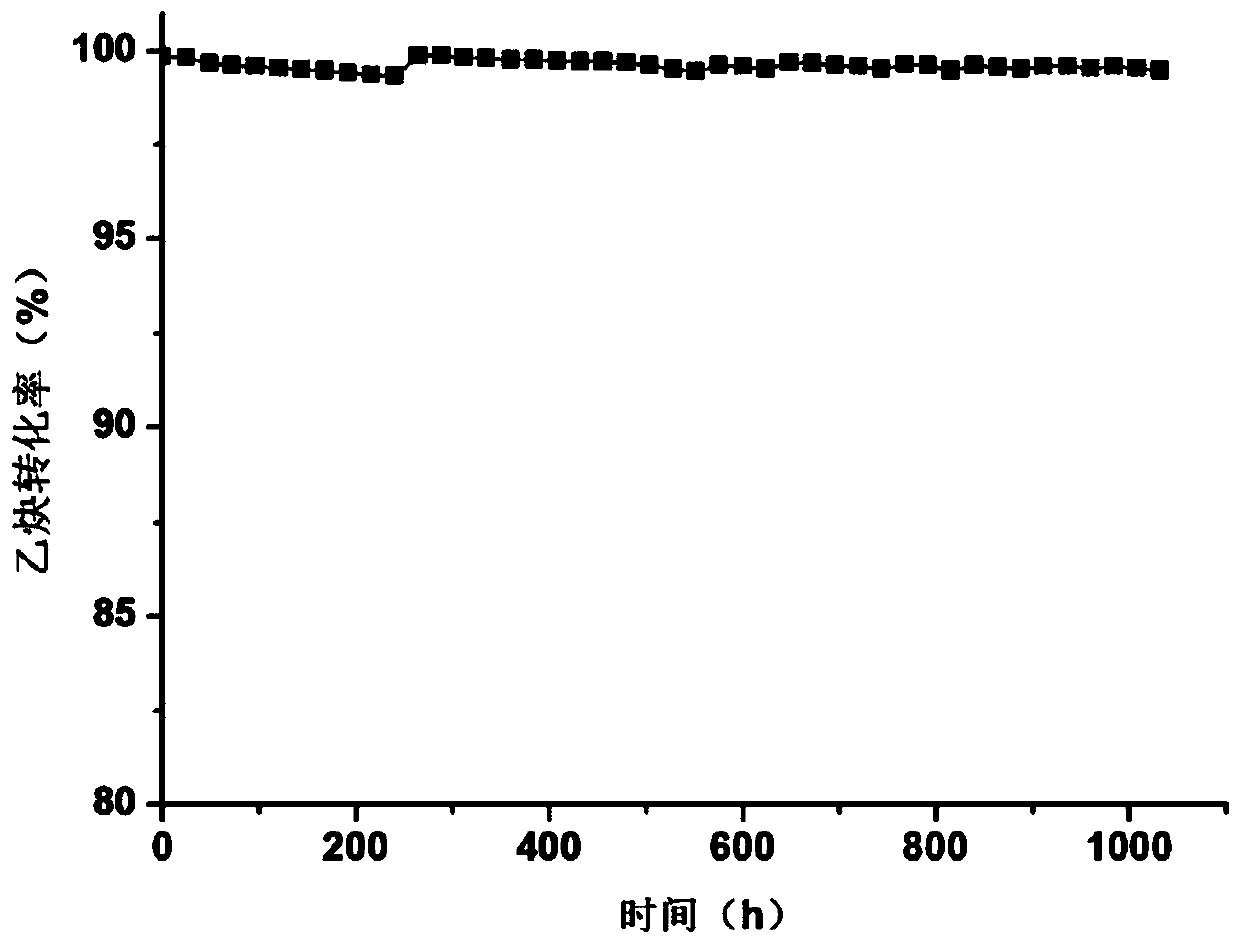

A composite catalyst and acetylene hydrochlorination technology, applied in the field of catalysis, can solve problems such as poor stability and rapid catalyst deactivation, and achieve the effects of improving performance, high added value of products, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Wash the columnar coconut shell activated carbon several times with tap water to remove surface impurities and ash, then slowly add it to 10% nitric acid aqueous solution, heat and boil for 1 hour. After cooling, soak and wash with deionized water repeatedly until the pH value of the washing liquid is above 4, and finally dry it in a blast drying oven at 120°C to obtain acid-treated columnar coconut shell activated carbon.

[0026] 2. According to the molar ratio of chloroauric acid to cysteine is 1:10, take 0.2mL 0.25mol / L chloroauric acid aqueous solution in a beaker, add deionized water to dilute to 20mL, then add 5mL 0.1mol / L The aqueous solution of L cysteine is turbid at the beginning, and the precipitate dissolves after being added dropwise to an excessive amount, and a gold-cysteine complex solution is obtained.

[0027] 3. According to the mass content of gold in the catalyst being 0.1%, and the mass content of copper chloride being 0.27%, take 10 g of...

Embodiment 2

[0029] 1. Wash the flaky coconut shell activated carbon several times with tap water to remove surface impurities and ash, then slowly add it to 10% nitric acid aqueous solution, heat and boil for 1 hour. After cooling, soak and wash with deionized water repeatedly until the pH value of the washing liquid is above 4, and finally dry it in a blast drying oven at 120°C to obtain acid-treated flaky coconut shell activated carbon.

[0030] 2. According to the molar ratio of chloroauric acid and glutamine as 1:10, take 0.1mL 0.25mol / L chloroauric acid aqueous solution in a beaker, add deionized water to dilute to 20mL, then add 2.5mL 0.1mol / L The aqueous solution of L glutamine had turbidity at the beginning, and the precipitate was dissolved after being added dropwise to an excessive amount, and a gold-glutamine complex solution was obtained.

[0031] 3. According to the mass content of gold in the catalyst being 0.05%, and the mass content of cerium chloride being 0.49%, take 10 ...

Embodiment 3

[0033] 1. Wash the columnar wood activated carbon several times with tap water to remove surface impurities and ash, then slowly add it to 20% nitric acid aqueous solution, heat and boil for 1 hour. After cooling, soak and wash with deionized water repeatedly until the pH value of the washing liquid is above 4, and finally dry it in a blast drying oven at 120°C to obtain acid-treated columnar wood activated carbon.

[0034] 2. According to the molar ratio of chloroauric acid to cysteine is 1:8, take 0.5mL 0.25mol / L chloroauric acid aqueous solution in a beaker, add deionized water to dilute to 20mL, then add 10mL 0.1mol / L The aqueous solution of L cysteine is turbid at the beginning, and the precipitate dissolves after being added dropwise to an excessive amount, and a gold-cysteine complex solution is obtained.

[0035] 3. According to the mass content of gold in the catalyst being 0.25%, the total mass content of cupric chloride and cobalt chloride being 0.53%, take 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com