Lithium ion battery cathode material, and preparation method thereof

A lithium-ion battery and cathode material technology, which is applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of electrode polarization and cycle instability, and achieves simple and reliable modification methods, low dosage, Strong universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

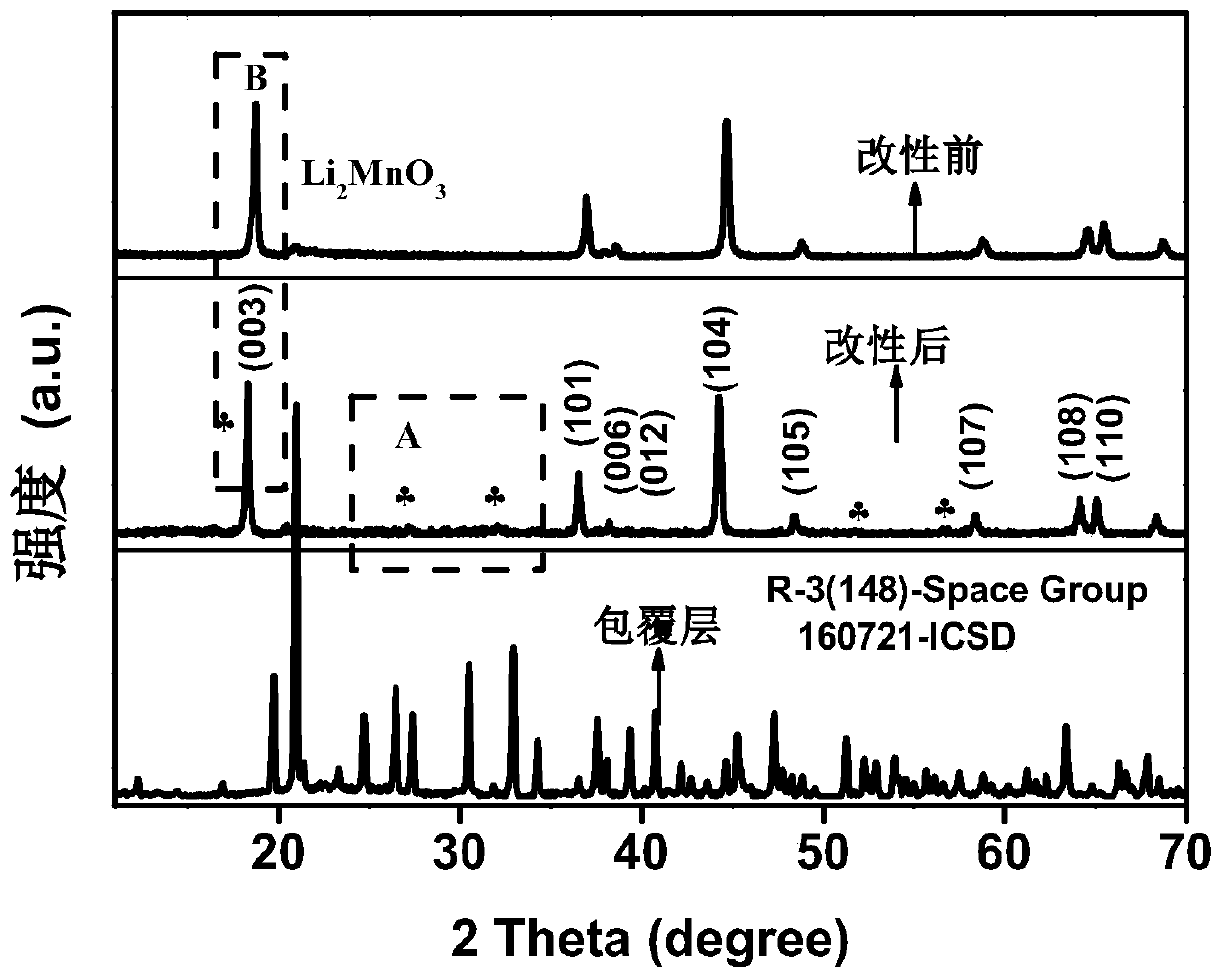

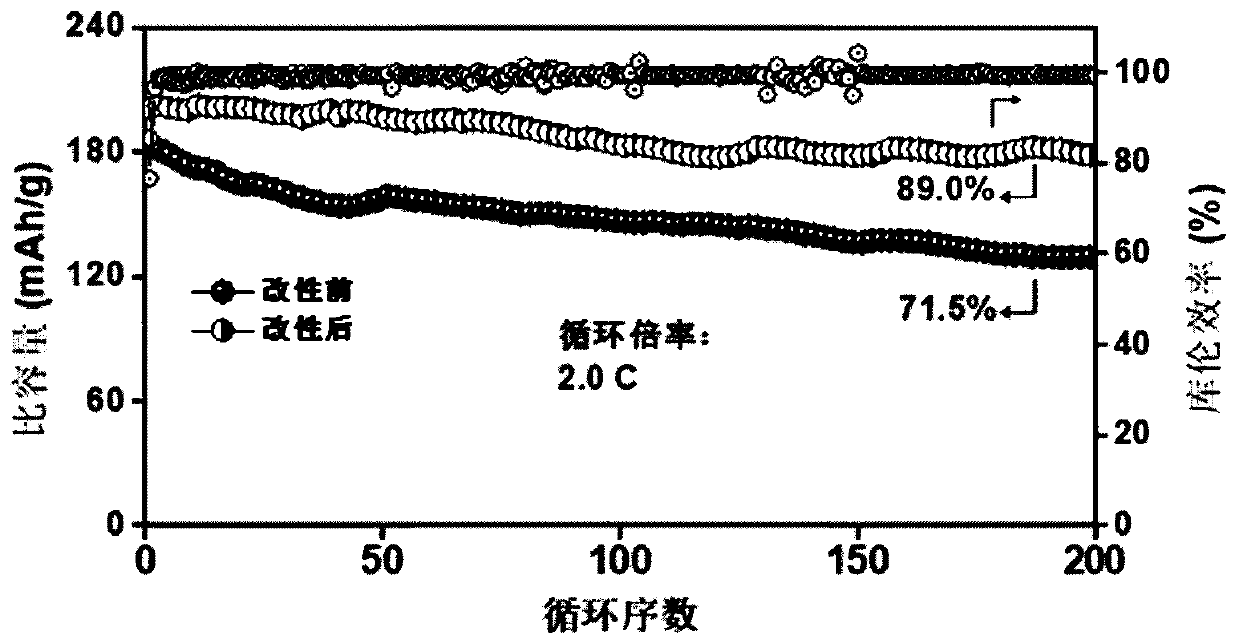

Image

Examples

Embodiment 1

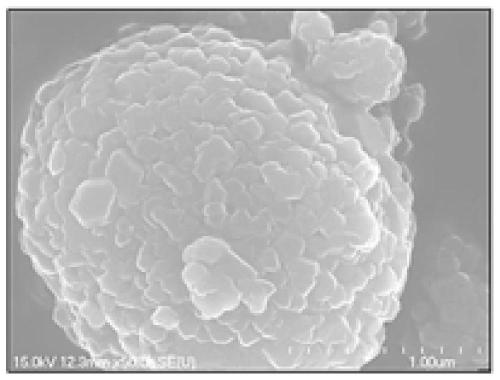

[0032] Step 1: preparing a lithium-rich manganese-based material with a spherical shape, the method is a carbonate co-precipitation method;

[0033]Step 2: Dissolve lithium hydroxide and tungsten trioxide powders with a molar ratio of 2:1 in deionized water at the same time, and stir the solution for 10 hours, so that the solution becomes a milky white turbid liquid;

[0034] Step 3: According to the coating amount of lithium tungstate being 2-4wt% of the lithium-rich manganese-based material, disperse the lithium-rich manganese-based material in the turbid liquid obtained in step 2, stir at room temperature for 120 minutes, and place in a water bath at 80°C Evaporate to dryness, the optimal duration of the process of evaporation to dryness is 6h;

[0035] Step 4: Grinding the black powder obtained after evaporating to dryness to make it completely dispersed;

[0036] Step 5: Sinter the black powder obtained in step 4 at a high temperature in an air atmosphere, the sintering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com