A device and method for measuring strain tensor in two-dimensional materials based on optical triple frequency

A two-dimensional material and strain tensor technology, which is applied in the field of spectroscopy and optoelectronics, can solve problems such as center inversion breaking and achieve fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

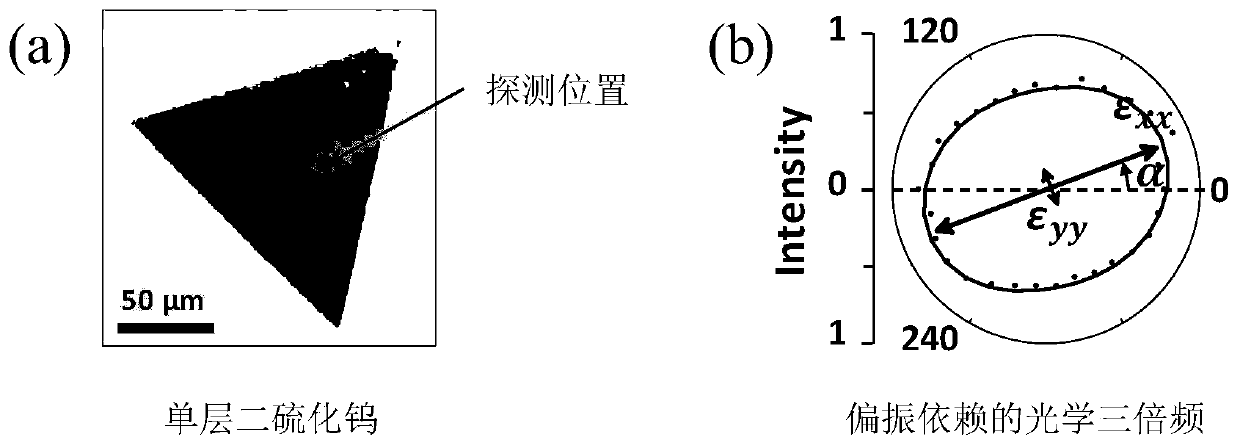

[0024] The measurement of the local strain tensor in single-layer tungsten disulfide by optical triple frequency includes the following steps:

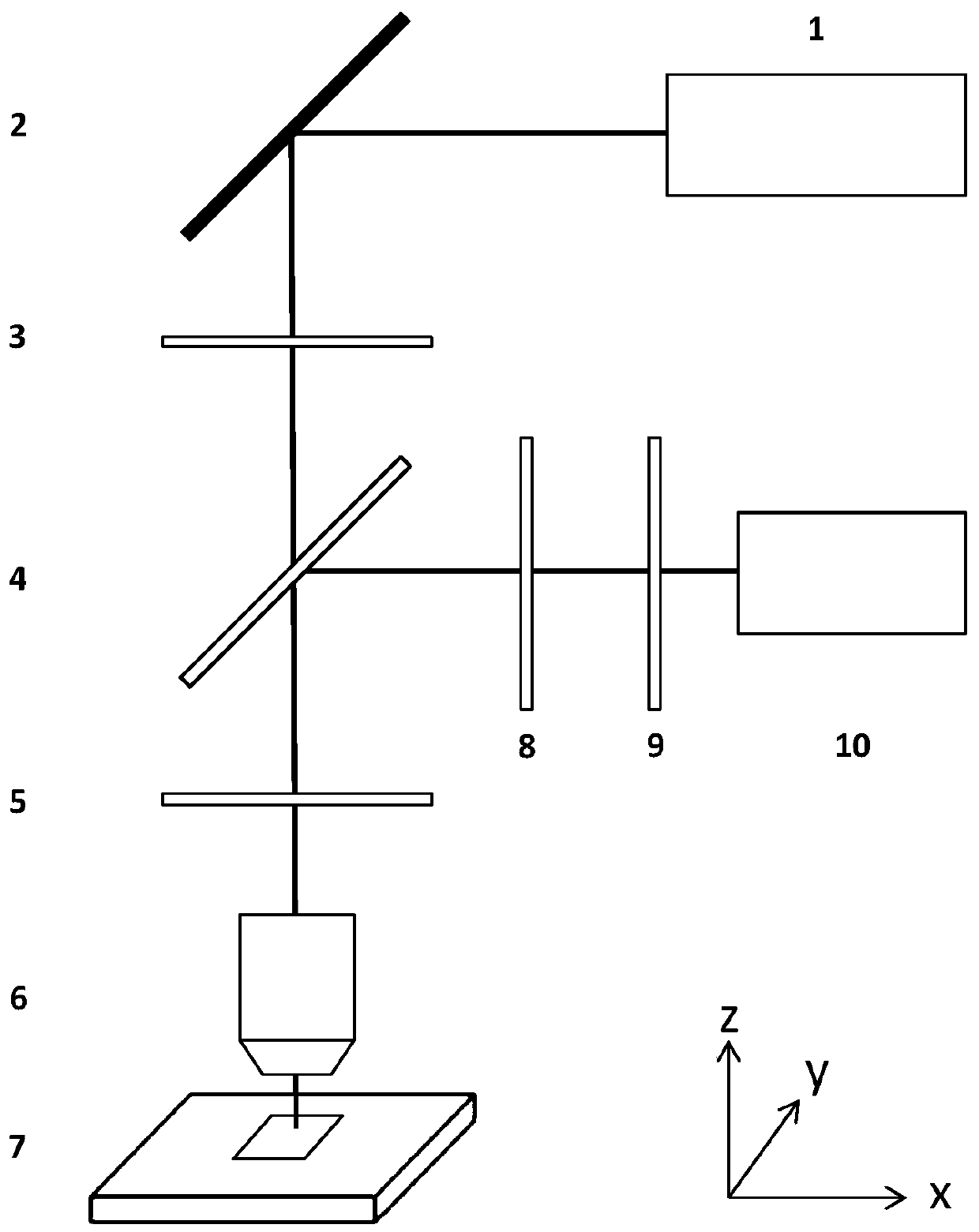

[0025] 1) if figure 1 As shown, the optical path includes a pulsed laser light source 1, a mirror 2, a first polarizer 3, a beam splitter 4, a 1 / 2 wave plate 5, a lens 6, a two-dimensional sample to be measured 7, a second polarizer 8, a filter Sheet 9, spectrometer 10. Among them, the pulse laser light source 1 has a wavelength of 1288nm, and the two-dimensional material sample to be tested is a single-layer tungsten disulfide.

[0026] Along the light emitting direction of the light source, the light source, the reflector, the first polarizer, the 1 / 2 wave plate, the beam splitter, the lens, and the measured two-dimensional material sample And its substrate, the lens, the beam splitter, the filter, the second polarizer, and the spectrometer are set in sequence.

[0027] 2) At the focal point of the lens 6, place a single layer of...

Embodiment 2

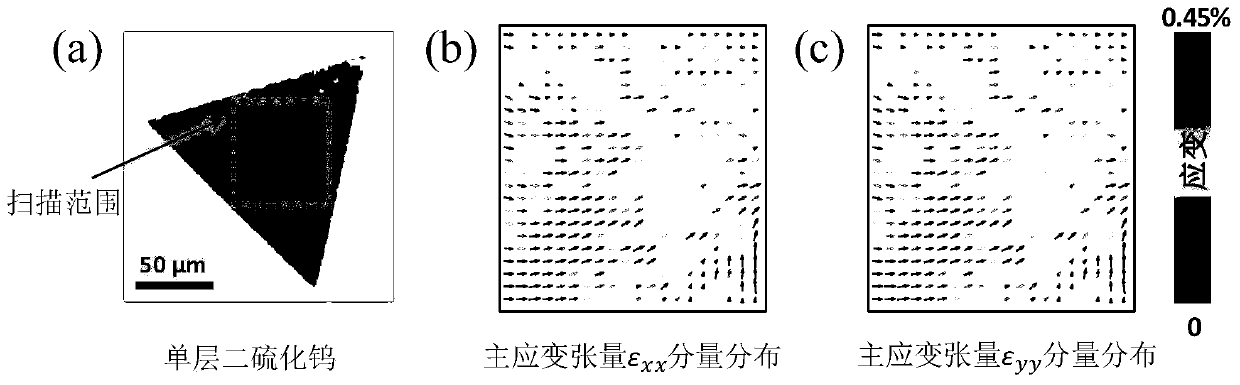

[0039] The measurement of the strain tensor distribution in the monolayer tungsten disulfide by optical triple frequency includes the following steps:

[0040] 1) if figure 1 As shown, the optical path includes a pulsed laser light source 1, a mirror 2, a first polarizer 3, a beam splitter 4, a 1 / 2 wave plate 5, a lens 6, a two-dimensional sample to be measured 7, a second polarizer 8, a filter Sheet 9, spectrometer 10. Among them, the pulsed laser light source 1 has a wavelength of 1288nm, and the two-dimensional material sample to be measured is a single-layer tungsten disulfide, which is placed on a two-dimensional piezoelectric displacement platform.

[0041] Along the light emitting direction of the light source, the light source, the reflector, the first polarizer, the 1 / 2 wave plate, the beam splitter, the lens, and the measured two-dimensional material sample And its substrate, the lens, the beam splitter, the second polarizer, the filter, and the spectrometer are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com