Graphene-like carbon-coated nickel selenide composite material and preparation method thereof

A graphene carbon and composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of harsh reaction conditions, complex solvent method steps, etc., and achieve a simple preparation method, few by-products, and easily controllable reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 0.374g of nickelocene and 0.16g of selenium powder into a 20ml stainless steel autoclave, seal it and place it in a crucible furnace capable of temperature programming. The furnace temperature rises from room temperature to 700°C, then maintained at 700°C for 10 hours, then cooled naturally to room temperature, collected the black deposits stuck on the inner surface of the kettle wall, washed them with distilled water and absolute ethanol for several times, and obtained graphene-like carbon packets after filtration. Coated nickel selenide nanomaterials. The yield of product-like graphene carbon-coated nickel selenide is 90%.

[0030] The product was dried in a vacuum oven at 50°C for 4 hours, and finally collected for characterization. Its shape and properties are as Figure 1~4 .

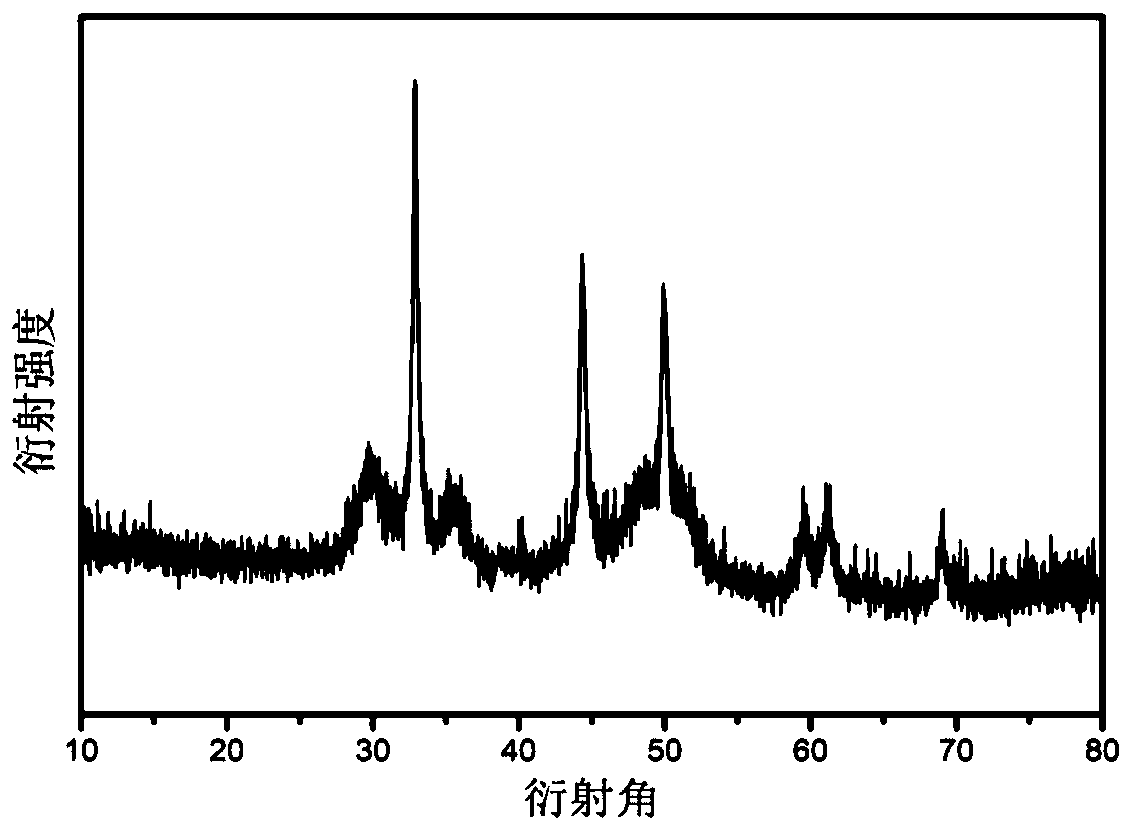

[0031] Depend on figure 1 It can be seen that in the X-ray diffraction spectrum, there are all diffraction peaks at 2θ at 10° to 80°, among which the diffraction intensity is high an...

Embodiment 2

[0036] Add 0.374g of nickelocene and 0.16g of selenium powder into a 20ml stainless steel autoclave, seal it and place it in a crucible furnace capable of temperature programming. The furnace temperature rises from room temperature to 600°C, then maintained at 600°C for 5 hours, then cooled naturally to room temperature, collected the black deposits stuck to the inner surface of the kettle wall, washed them with distilled water and absolute ethanol for several times, and obtained graphene-like carbon packets after filtration. Coated nickel selenide nanomaterials. The yield of product-like graphene carbon-coated nickel selenide is 80%.

[0037] The product was dried in a vacuum oven at 50°C for 4 hours, and finally collected for characterization. Its shape and characteristics are as Figure 5-6 shown.

[0038] Depend on Figure 5 It can be seen that in the X-ray diffraction spectrum, there are all diffraction peaks at 2θ at 10° to 80°, among which the diffraction intensity ...

Embodiment 3

[0041] Add 0.374g of nickelocene and 0.16g of selenium powder into a 20ml stainless steel autoclave, seal it and put it into a crucible furnace capable of temperature rise. The furnace temperature rises from room temperature to 650°C, then maintained at 650°C for 15 hours, then cooled naturally to room temperature, collected the black deposits stuck on the inner surface of the kettle wall, washed them with distilled water and absolute ethanol for several times, and obtained graphene-like carbon packets after filtration. Coated nickel selenide nanomaterials. The yield of product class graphene nickel selenide is 85%.

[0042] The product was dried in a vacuum oven at 50°C for 4 hours, and finally collected for characterization. Its shape and characteristics are as Figure 7-8 shown.

[0043] Depend on Figure 7 It can be seen that in the X-ray diffraction spectrum, there are all diffraction peaks at 2θ at 10° to 80°, among which the diffraction intensity is high and the pea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com