Eye pad to improve dry eye syndrome via nano transdermal technique and preparation method thereof

A dry eye, transdermal technology, applied in non-active ingredients medical preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of difficult to cure, low bioavailability, etc., to promote blood circulation , Improve storage stability, improve dry eye syndrome and visual fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Dissolve 0.1g of sodium alginate and 0.01g of calcium chloride in 10ml of distilled water respectively.

[0025] (2) Dissolve 0.5ug epidermal growth factor, 1mg cyclosporine A, and 0.05mg wolfberry extract in sodium alginate stock solution, and stir for 1h.

[0026] (3) Add calcium chloride aqueous solution to the above 2 solutions within 30 minutes under stirring conditions, and continue stirring for 15 minutes to complete the pre-gelation process.

[0027] (4) Next, 0.01 g of chitosan was dissolved in 10 ml of acetic acid (2% concentration by mass), and added dropwise to the above-mentioned 3 pregels, and continued to stir for 30 min to form nanoparticles.

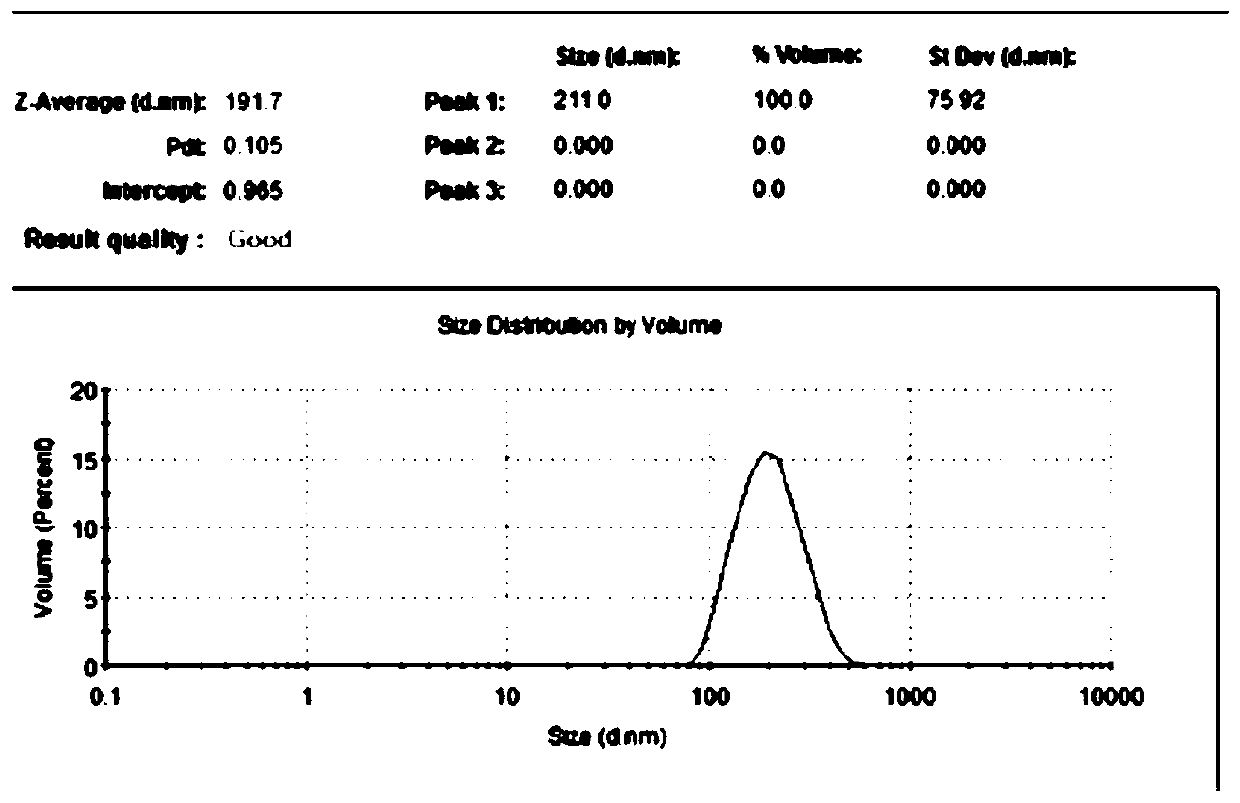

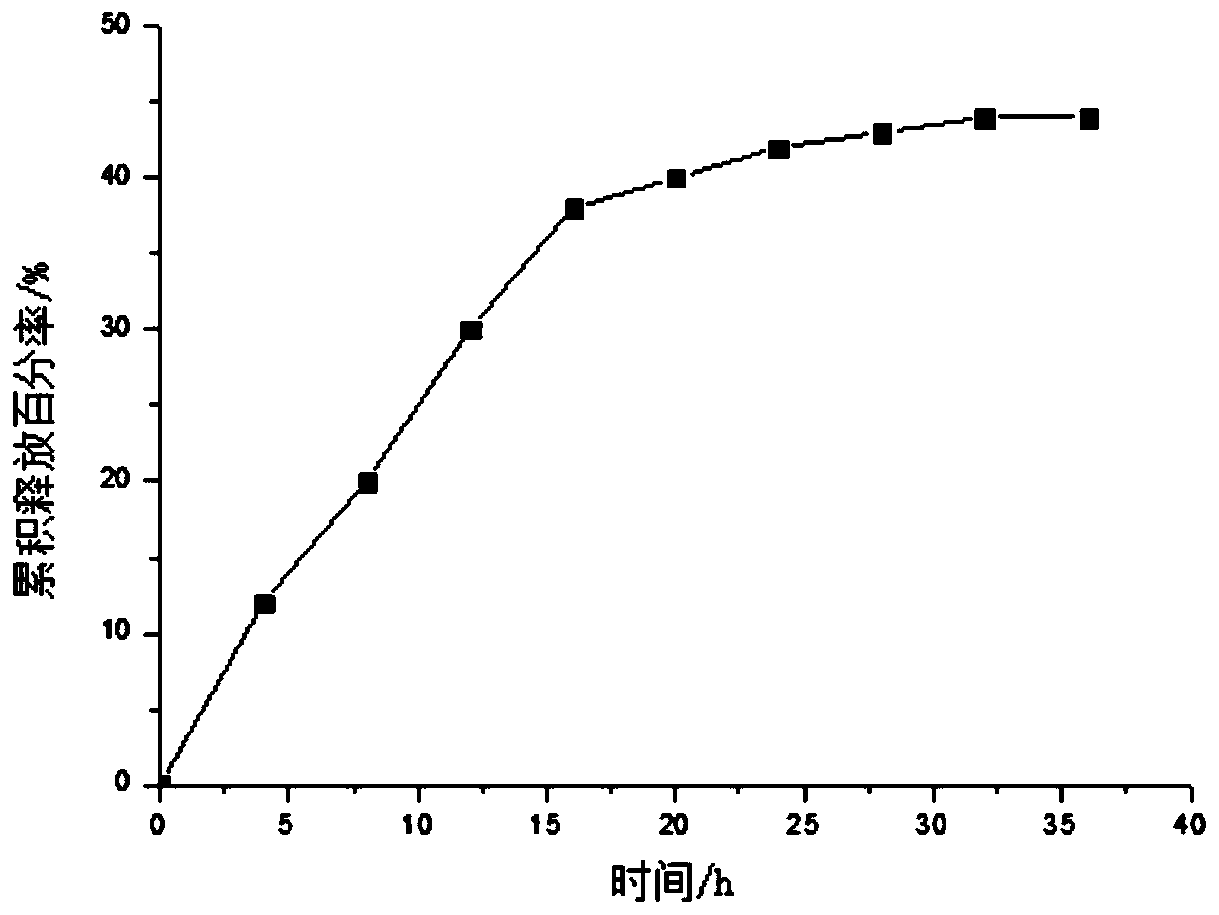

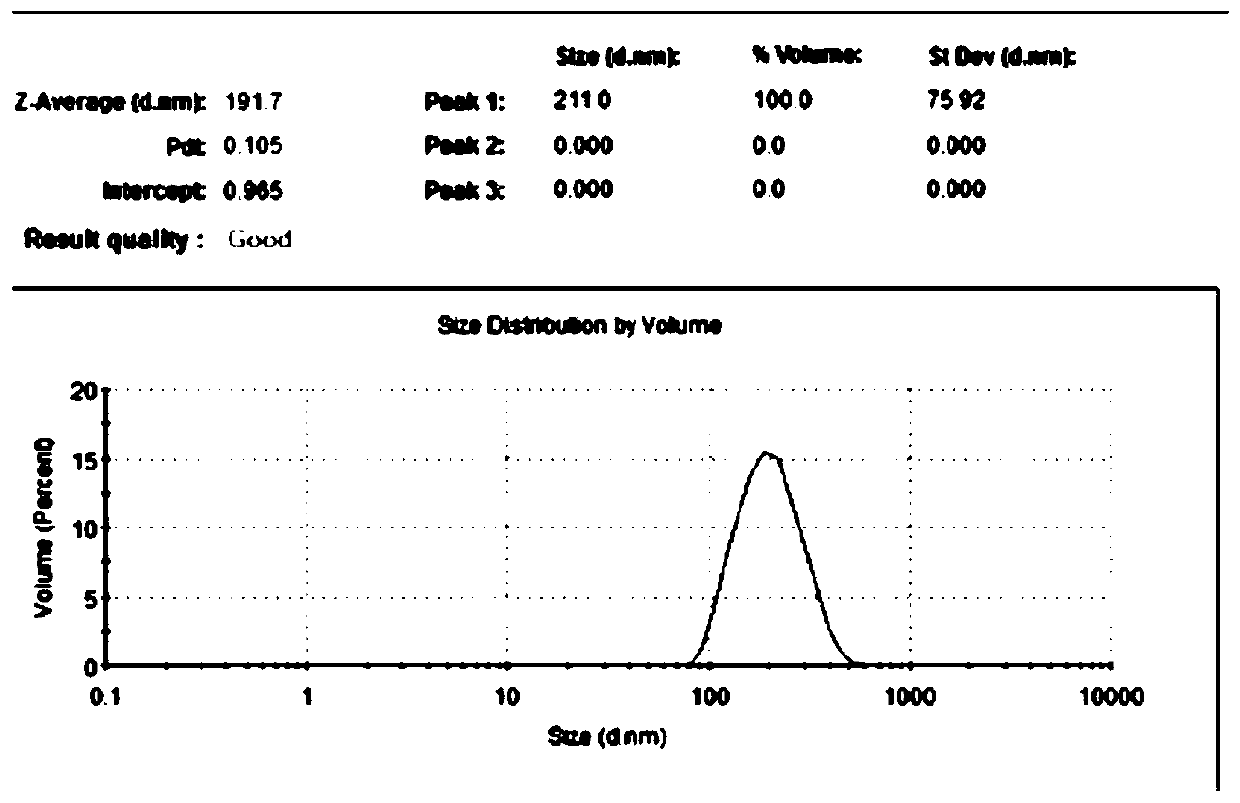

[0028] (5) Ultrasonic dispersion for 20 minutes to prevent aggregation, and centrifugation at 11,000 rpm for 40 minutes to freeze-dry to powder.

[0029] (6) Redissolve the above powder, add borneol and menthol, stir and mix, filter, and sterilize to obtain the eye patch.

[0030] (7) Soak the non-woven fabr...

Embodiment 2

[0033] (1) Dissolve 0.1g of sodium alginate and 0.01g of calcium chloride in 10ml of distilled water respectively.

[0034] (2) Dissolve 0.05 mg wolfberry extract, 0.1 mg cassia seed extract and 1 mg cyclosporine A in sodium alginate stock solution, and stir for 1 h.

[0035] (3) Add calcium chloride aqueous solution to the above 2 solutions within 30 minutes under stirring conditions, and continue stirring for 15 minutes to complete the pre-gelation process.

[0036] (4) Next, dissolve 0.01g of chitosan in 10ml of acetic acid (2%), and add dropwise to the above-mentioned 3 pregels, and continue to stir for 30min to form nanoparticles.

[0037] (5) Ultrasonic dispersion for 30 minutes to prevent aggregation, and centrifugation at 11,000 rpm for 40 minutes to freeze-dry to powder.

[0038] (6) Redissolve the above powder, add borneol and menthol, stir and mix, filter, and sterilize to obtain the eye patch.

[0039] (7) Put the non-woven fabric into the eye patch solution obta...

Embodiment 3

[0041] Eye patch nano-transdermal technology for improving dry eye syndrome

[0042] (1) Dissolve 0.1g of sodium alginate and 0.01g of calcium chloride in 10ml of distilled water respectively.

[0043] (2) Dissolve 0.05ug epidermal growth factor, 0.01mg lutein and 1mg vitamin A, 0.05mg wolfberry extract in sodium alginate stock solution, and stir for 1h.

[0044] (3) Add calcium chloride aqueous solution to the above 2 solutions within 30 minutes under stirring conditions, and continue stirring for 15 minutes to complete the pre-gelation process.

[0045] (4) Next, dissolve 0.02g of chitosan in 10ml of acetic acid (2%), and add dropwise to the above-mentioned 3 pregels, and continue to stir for 30min to form nanoparticles.

[0046] (5) Ultrasonic dispersion for 10 minutes to prevent aggregation, and centrifugation at 11,000 rpm for 40 minutes to freeze-dry to powder.

[0047] (6) Redissolve the above powder, add borneol and menthol, stir and mix, filter, and sterilize to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com