Modified nanoparticle suspension as well as preparation method and application thereof

A nanoparticle and suspension technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of nanoparticle agglomeration, difficult agglomeration of nanoparticles, and fouling of separation membranes, achieving simple process and easy raw materials. The effect of obtaining, increasing hydrophilicity or oleophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

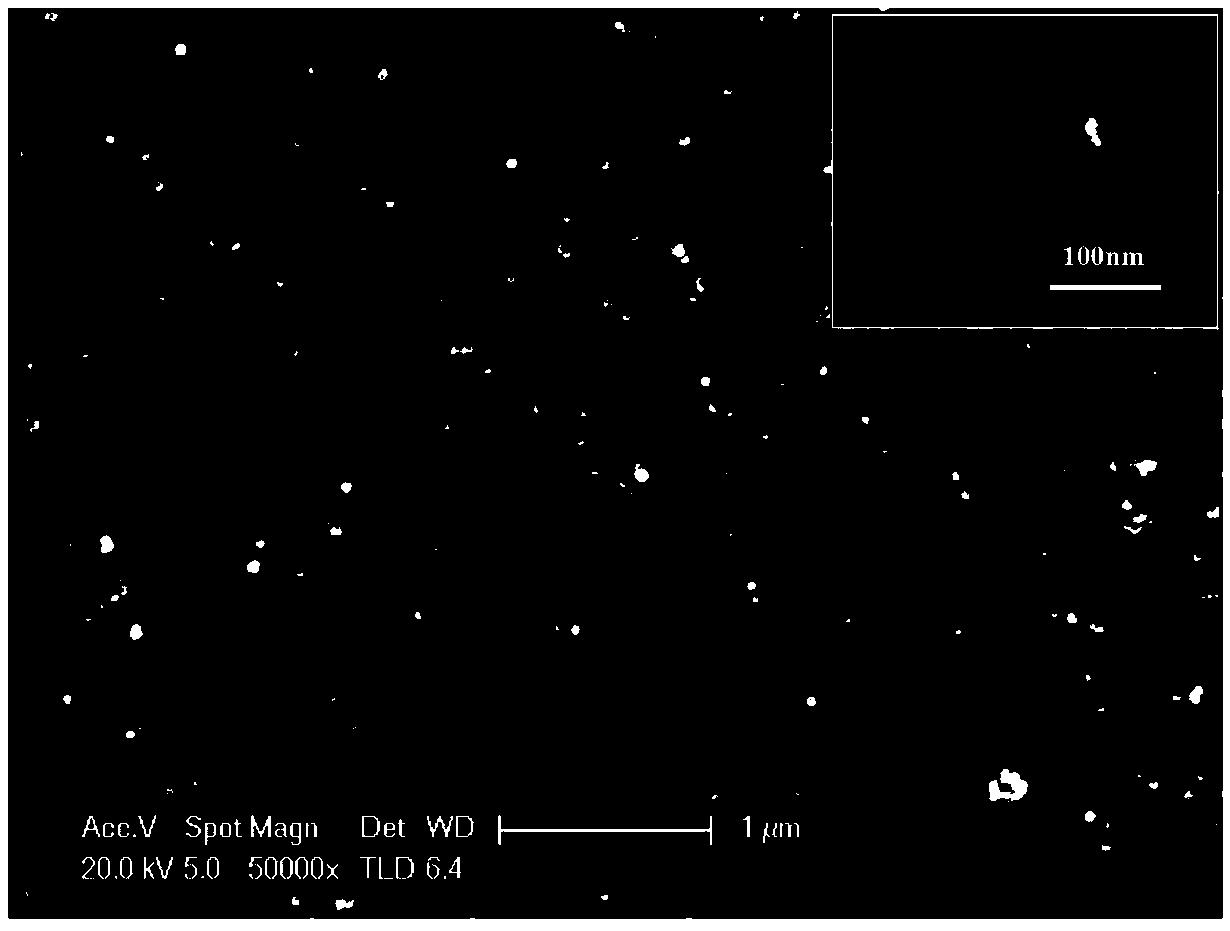

[0030] At room temperature, 9 parts by volume of 25 vt.% ammonia solution and 16 parts by volume of deionized aqueous solution were ultrasonically dispersed and mixed for 5 minutes, and then 2 parts by mass of silica sol was added dropwise, and a clear mixed solution was obtained after ultrasonic dispersion for 5 minutes. The silica sol is water-based nano-silica sol, wherein the mass concentration of nano-silica is 15-30%, and the average particle diameter is 5-20 nm. Chain particles or loosely combined into beaded particles of 40-100 nm; the above mixed solution was added dropwise to 180 parts by volume of ethanol, ultrasonicated for 5 minutes, then mechanically stirred for 5 minutes, and then 1.2 parts by volume of normal Tetraethyl silicate solution, continue mechanical stirring for 15 min, then add 1.2 parts by volume of 2 wt.% polyvinyl alcohol solution dropwise, and finally obtain a hydrophilic modified stable solution after continuous mechanical stirring for 12 h; The ...

Embodiment 2

[0032] Within 60 minutes, the 20 parts of the solid content of 15% hydrophilic modified SiO prepared in the above example 1 were prepared by using a spraying process with a spraying pressure of 0.5 MPa and a spray gun with a nozzle diameter of 0.5 mm. 2 The nanoparticle suspension was sprayed into 100 parts of continuous planetary mixing PTFE powder (hydrophilic modified nano-SiO 2 Particles and PTFE powder mass ratio is 3%), the hydrophilic modified nanoparticles can be uniformly dispersed in the PTFE powder, and then prepared into a hydrophilic hollow fiber membrane, the water contact angle of the hydrophilic hollow fiber membrane is 45.1°, while Yu Liyun et al. used the phase inversion method to directly blend nanoparticles with raw materials, SiO 2 When the particle content is 3%, the water contact angle is the lowest at 68.7°. Therefore, the modified particles are added into the hollow fiber membrane in the form of suspension, and the antifouling is better.

Embodiment 3

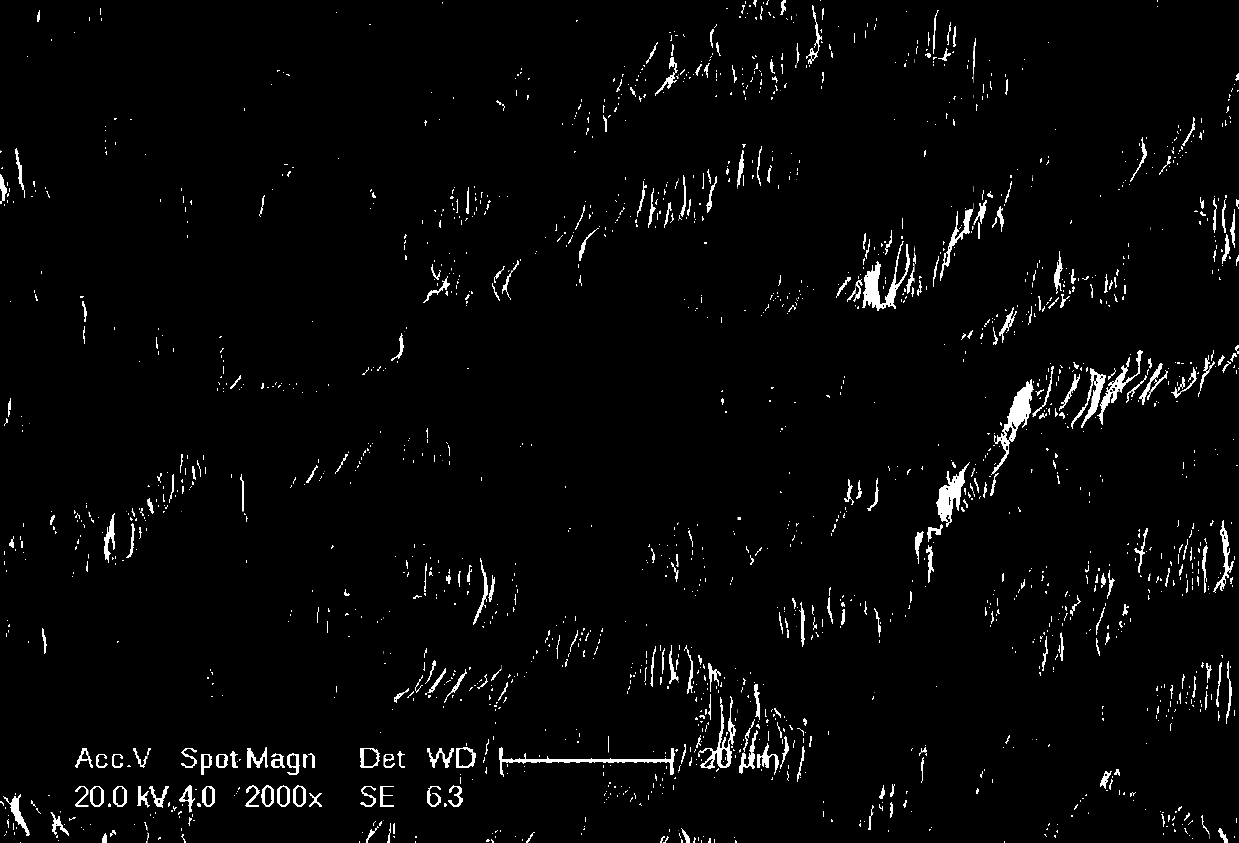

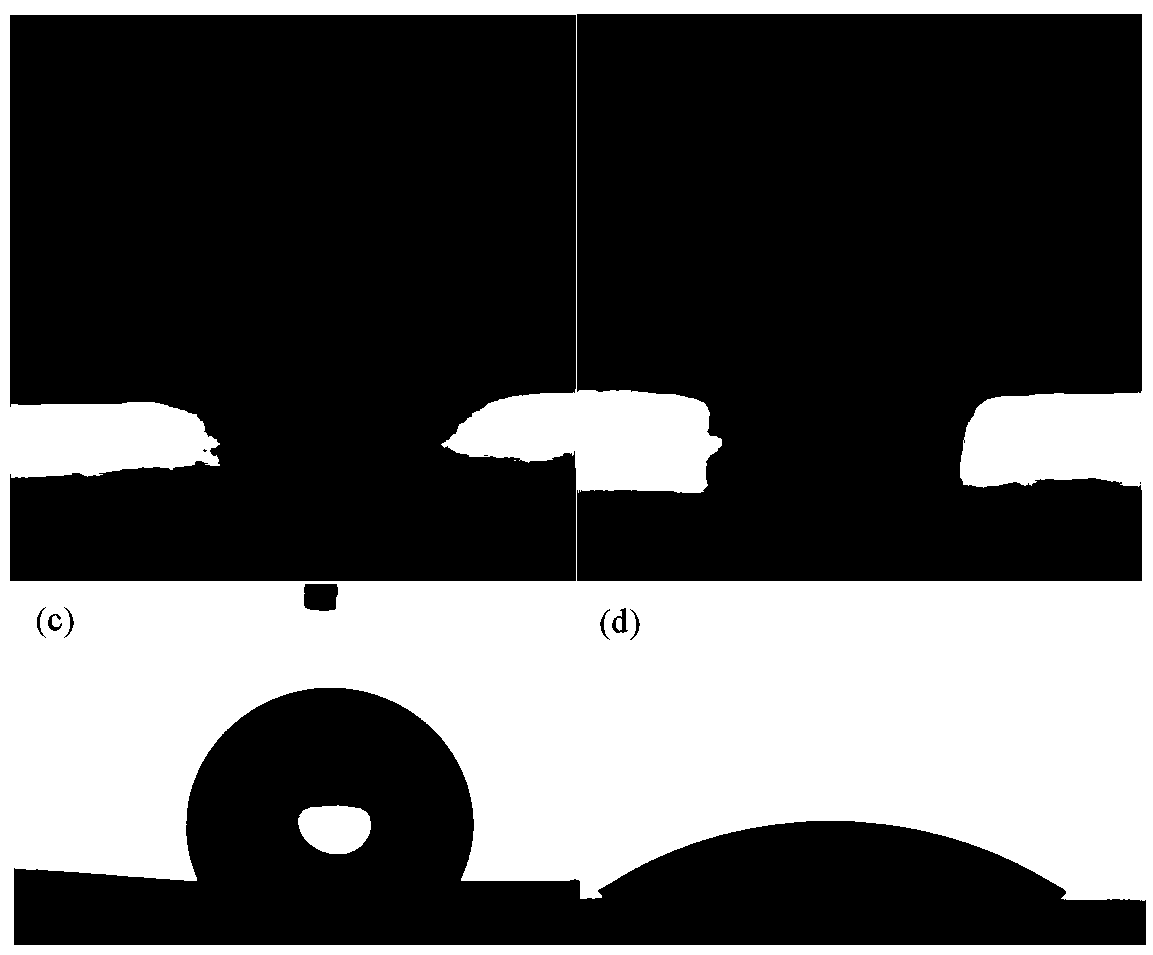

[0034] Within 60 minutes, the spraying process is a spraying pressure of 0.5 MPa, a spray gun with a nozzle diameter of 0.5 mm, and 100 parts of the modified nanoparticle suspension prepared in the above-mentioned embodiment 1 is sprayed to 100 parts of continuous planetary mixing In PTFE powder (hydrophilic modified nano-SiO 2 The mass ratio of particles to PTFE powder is 15%), the hydrophilic modified nanoparticles can be uniformly dispersed in the PTFE powder, and then prepared into a hydrophilic hollow fiber membrane. The prepared hollow fiber membrane microscopic scanning diagram is shown in figure 2 . Tests the wettability of a water droplet on its surface ( image 3 b), compared to pristine hollow fiber membranes ( image 3 a) Enhanced hydrophilicity. The water contact angle of the original hollow fiber membrane ( image 3 c) is 138.5°, the water contact angle of the hydrophilic hollow fiber membrane ( image 3 d) is 10.1°, and SiO 2 When the mass ratio of PTFE p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com