Resin adsorption treatment process of high-salt wastewater containing amine system

A resin adsorption, high-salt wastewater technology, applied in adsorption water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. There are high requirements for quality, etc., to achieve the effect of good decolorization effect, easy crystallization, and high salt whiteness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

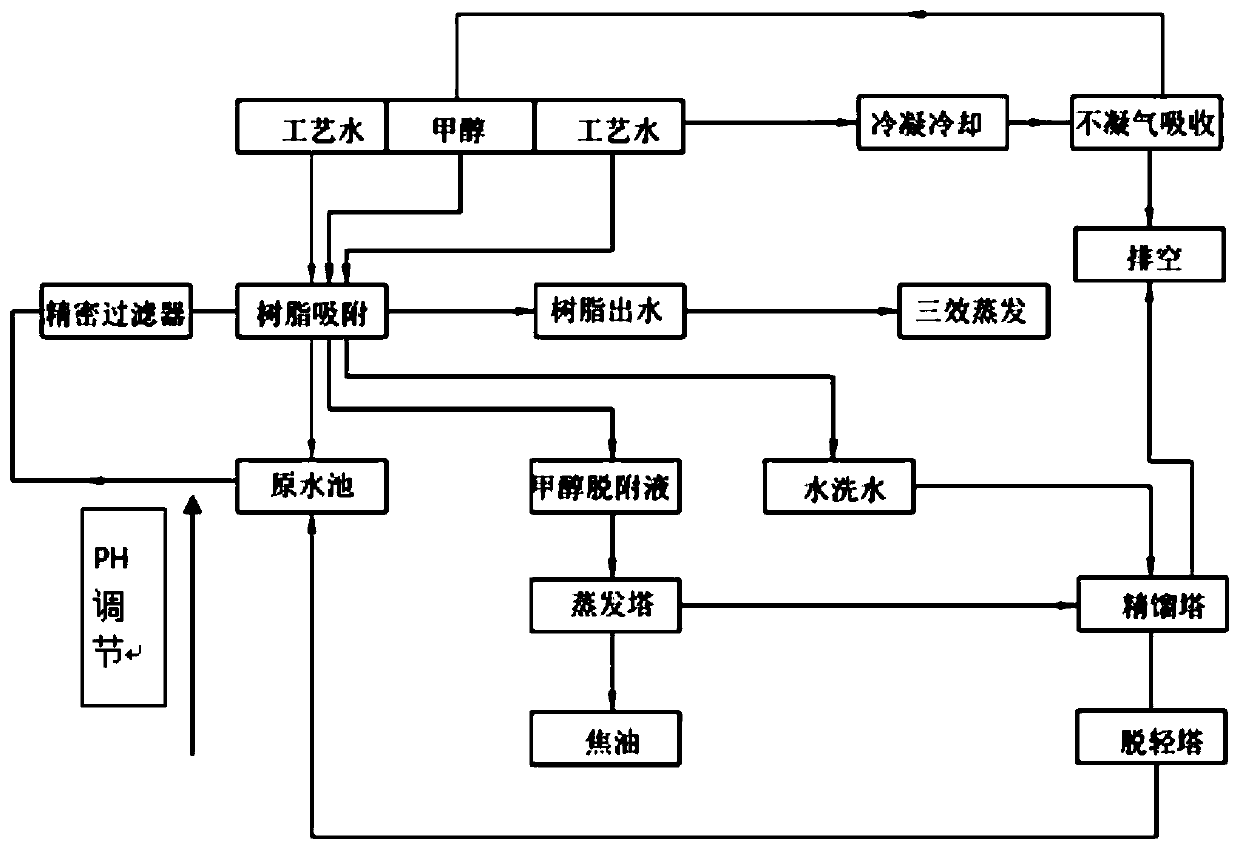

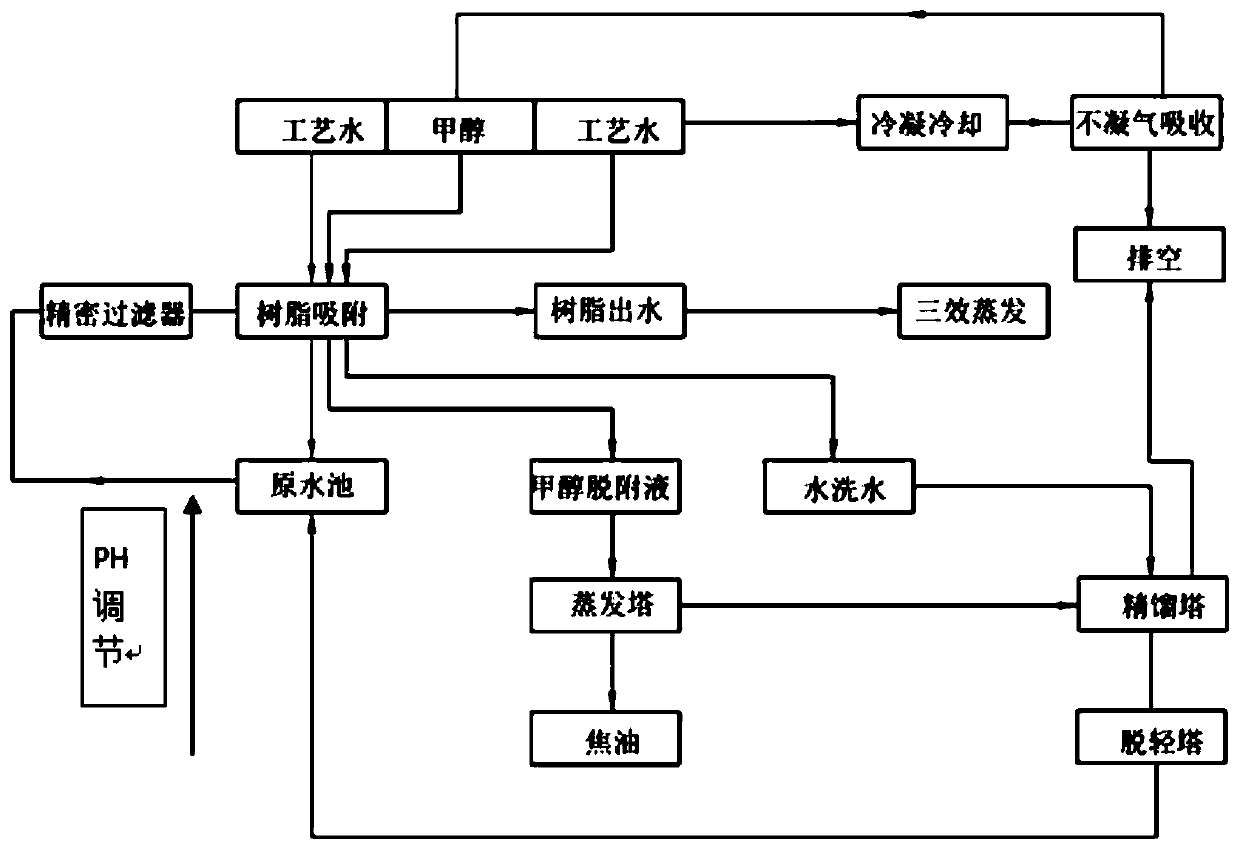

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] An amine-containing system high-salt wastewater resin adsorption treatment process mainly includes the following specific steps:

[0018] (1) Raw water filtration: The raw water is pumped into the raw water tank after the pH is adjusted to be neutral, and the raw water is pumped into the precision filter through the lift pump to filter out mechanical impurities, and the effluent enters the resin adsorption tower.

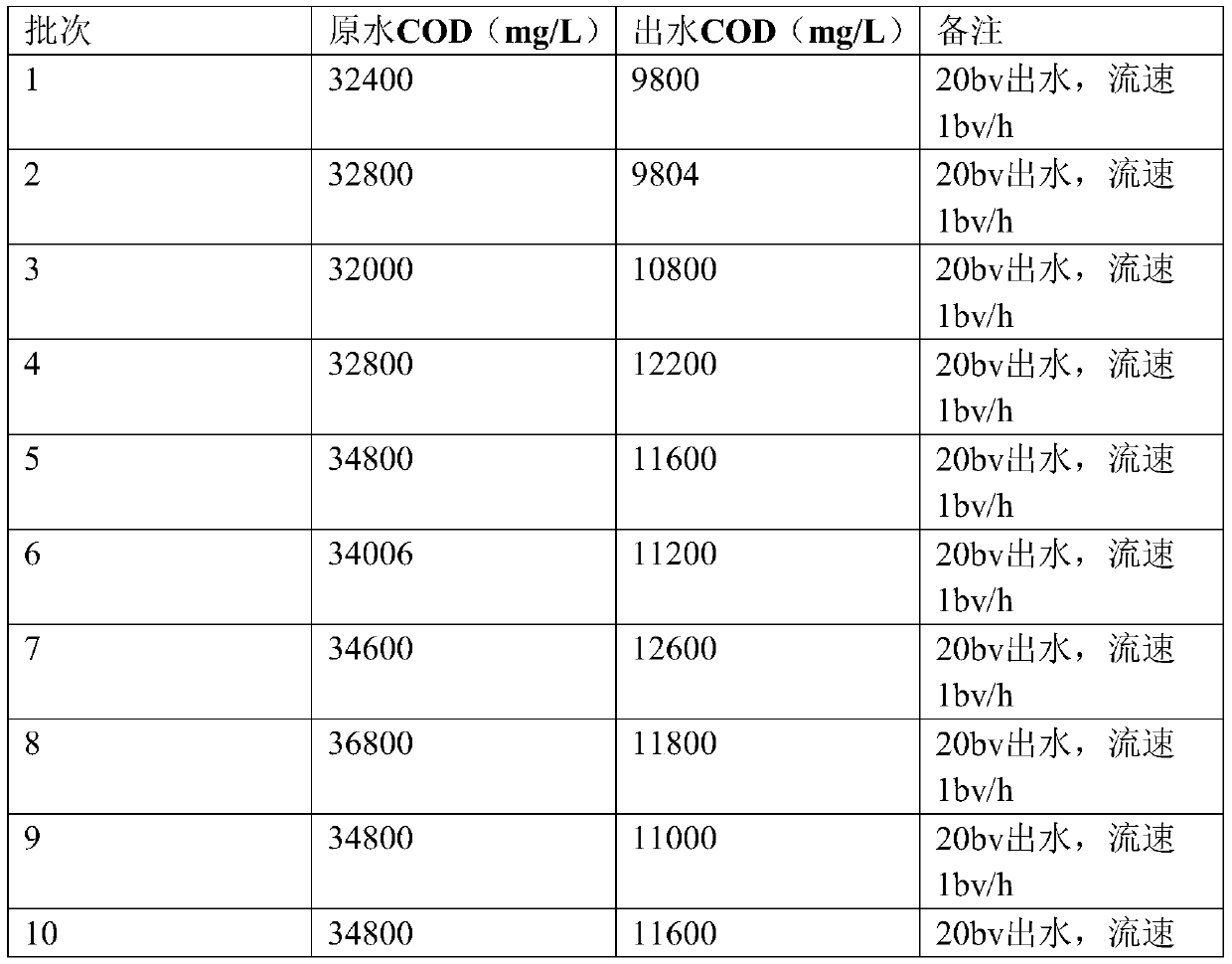

[0019] (2) Resin adsorption: select JD-015 type resin to adsorb, and the effluent enters the resin effluent tank, directly enters the three-effect evaporation for evaporation and crystallization, and returns the mother liquor to the raw water buffer tank.

[0020] (3) Resin desorption: the process water enters the resin adsorption tower for washing, and the washing water enters the raw water tank, and then desorbs with methanol, and the meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com