Bacterial nanocellulose base tube with inner surface texture modification and preparation method and application thereof

A nanocellulose, inner surface technology, applied in medical science, prosthesis, etc., can solve the problems of difficult direct molding and difficult texture modification, and achieve the effect of controllable mechanical properties and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Dehydration treatment of BNC membrane

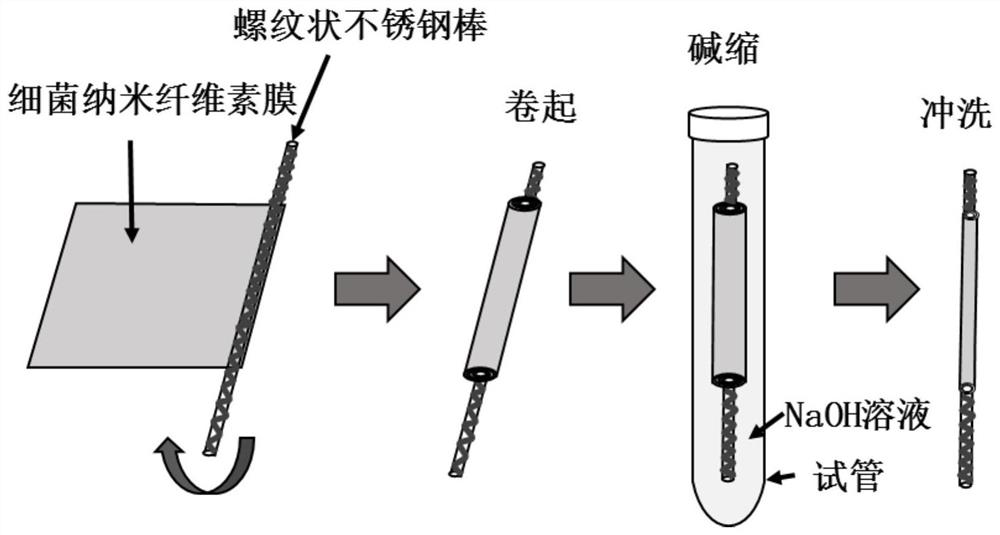

[0031] A square BNC membrane with a thickness of 2-3mm, a side length of 5cm, a cellulose content of 0.3%, and a water holding capacity of 99.7% is placed on the filter paper, and about 80% of the water in the cellulose membrane is sucked out, along a diameter of 3mm. , and the stainless steel rod with spiral pattern on the surface is rolled up to form a BNC multi-layer tube with a length of 5cm ( figure 1 ), fastened with a rope.

[0032] (2) Preparation of concentrated alkali solution

[0033] The ultrapure water was boiled for 10 minutes, sealed and cooled to reduce dissolved oxygen in the water, and a sodium hydroxide solution with a concentration of 20% (w / v) was prepared with it, sealed, and placed at room temperature for later use.

[0034] (3) Texture modification of BNC multilayer tube

[0035] The BNC multi-layer tube with a length of 5 cm prepared in step (1) was placed in the sodium hydroxide solution described...

Embodiment 2

[0042] (1) Preparation of bacterial nanocellulose tubes

[0043] A BNC tube with an inner diameter of 3 mm, an outer diameter of 8 mm and a length of 10 cm was prepared by the static incubation method. After being boiled with 1% NaOH lye solution at 80°C for 4 hours, it was repeatedly replaced with ultrapure water until it became neutral to obtain a purified BNC tube. .

[0044] (2) Preparation of concentrated lye

[0045] Prepare a sodium hydroxide solution with a concentration of 10-30% (w / v), seal it, and place it at room temperature for later use.

[0046] (3) Texture modification of BNC tube

[0047] The BNC tube obtained in step (1) is sleeved on a glass rod with a diameter of 3 mm and has a pattern, placed in the NaOH solution configured in step (2), and after shaking at room temperature for 15 minutes, the glass rod is removed, and ultrapure water or acetic acid is used. The aqueous solution is repeatedly washed until it is neutral to obtain a BNC pipe with patterns...

Embodiment 3

[0050] (1) Preparation of BNC / chitosan (BNC / CH) composite tube

[0051] Bacterial nanocellulose tubes with an inner diameter of 3 mm, a length of 5 cm, a wall thickness of 2.5 mm, a cellulose content of 0.3%, and a water holding capacity of 99.7% prepared by the static incubation method were soaked in a chitosan concentration of 1% and an acetic acid concentration of 1% ultrapure aqueous solution, shake it at room temperature (100rpm) for 24h, take it out, put it in a sodium hydroxide solution with a concentration of 0.1M, and let it stand for 24h, so that chitosan is deposited in the fiber network of bacterial nanocellulose tubes. ;

[0052] (2) Preparation of concentrated lye

[0053] Boil the ultrapure water for 10 minutes and then seal and cool it to reduce the dissolved oxygen in the water, and use it to prepare a sodium hydroxide solution with a concentration of 20% (w / v), seal it, and place it at room temperature for later use;

[0054] (3) Texture modification of BNC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com