Method for synthesizing ester lubricating oil by using molybdenum disulfide nanoparticles for catalysis and lubrication

A technology of molybdenum disulfide and nanoparticles, applied in the direction of molybdenum sulfide, lubricating compositions, chemical instruments and methods, etc., can solve the problems of difficult dispersion of molybdenum disulfide nanoparticles, high manufacturing cost, complicated reaction steps, etc., and achieve good economical Benefits and environmental protection value, improved lubrication performance, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] ① Preparation of molybdenum disulfide nanoparticles

[0025] Weigh 1.5g of ammonium dodecamolybdenum phosphopolyacid, dissolve in 50g, 12% potassium hydroxide solution, fully mix 3g of thioacetamide and the above solution under heating and stirring, and then use 5.5mol / L hydrochloric acid to adjust the pH value to 4. After the reaction, the obtained precipitated product was washed, filtered and dried to obtain molybdenum disulfide nanoparticles.

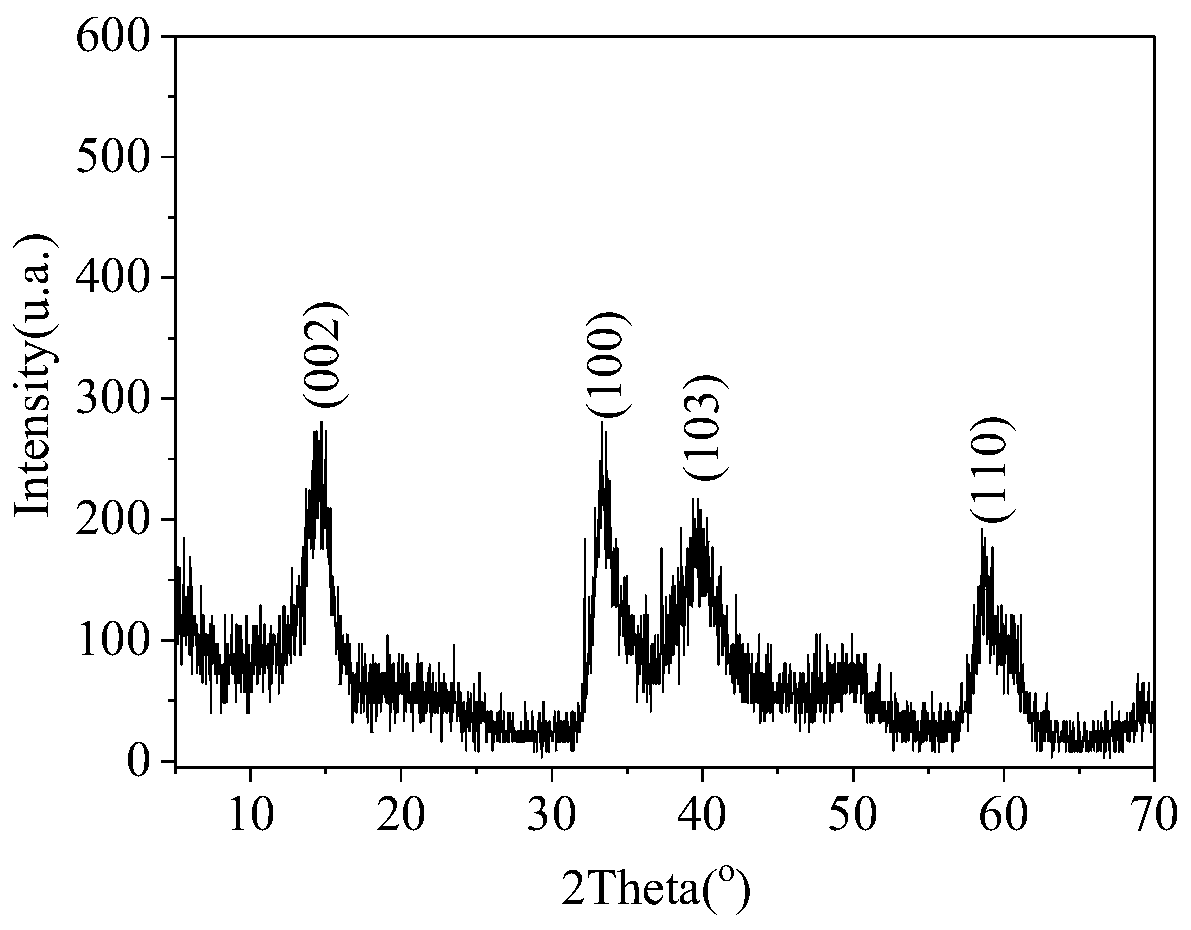

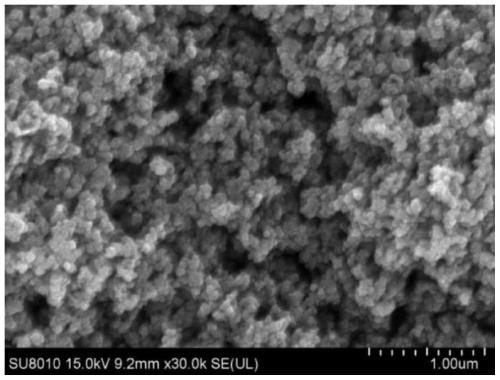

[0026] figure 1 , 2 They are the XRD pattern and scanning electron microscope pattern of the product obtained by reacting molybdenum disulfide with ammonium dodecamolybdenum phosphopolyacid and thioacetamide in Example 1, respectively. figure 1 Among the main diffraction peaks, there are 4 can be attributed to (002), (100), (103), (110) of molybdenum disulfide particles, indicating that molybdenum disulfide has been successfully prepared. figure 2 It is shown that the molybdenum disulfide is granular, and the average size ...

Embodiment 2

[0031] ① Preparation of molybdenum disulfide nanoparticles

[0032] Weigh 1.5g of ammonium dodecamolybdenum phosphopolyacid, dissolve in 75g, 10% potassium hydroxide solution, fully mix 3.75g of thioacetamide and the above solution under heating and stirring, and then use 4mol / L Phosphoric acid was used to adjust the pH value to 3. After the reaction, the precipitated product obtained was washed, filtered and dried to obtain molybdenum disulfide nanoparticles.

[0033] ② Synthesis of ester lubricating oil

[0034] Take a total of 100g of polyethylene glycol and oleic acid as raw materials, wherein the molar ratio of alcohol to acid is 1:2, add 10g of molybdenum disulfide nanoparticles to the raw material mixture, and use the surface active center of molybdenum disulfide nanoparticles as a catalyst. The esterification reaction was carried out under the condition of stirring at 150°C for 6 hours, and the water generated was removed by a water separator. Because the raw material...

Embodiment 3

[0036] ① Preparation of molybdenum disulfide nanoparticles

[0037] Weigh 1.5g of ammonium dodecamolybdenum phosphopolyacid, dissolve in 37.5g, 15% potassium hydroxide solution, fully mix 2.25g of thioacetamide and the above solution under heating and stirring, then use 7mol / L of hydrochloric acid to adjust the pH value to 3.5. After the reaction, the obtained precipitated product was washed, filtered and dried to obtain molybdenum disulfide nanoparticles.

[0038] ② Synthesis of ester lubricating oil

[0039]Take a total of 100g of raw materials octanol and sebacic acid, wherein the molar ratio of alcohol to acid is 2:1, add 1g of molybdenum disulfide nanoparticles to the raw material mixture, use the surface active center of molybdenum disulfide nanoparticles as a catalyst, and stir Carry out the esterification reaction at 100°C for 15 hours, and use a water separator to remove the generated water. Because the raw material is reacted on the surface of the catalyst, the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com