Electrochemical sensor for detecting bisphenol A, and preparation method and application thereof

An electrochemical and sensor technology, applied in the field of electrochemical analysis, can solve the problems of expensive instruments, complicated and cumbersome processing procedures, and the need for professionals to operate the instrument, and achieve the effects of improving conductivity, increasing sensitivity, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

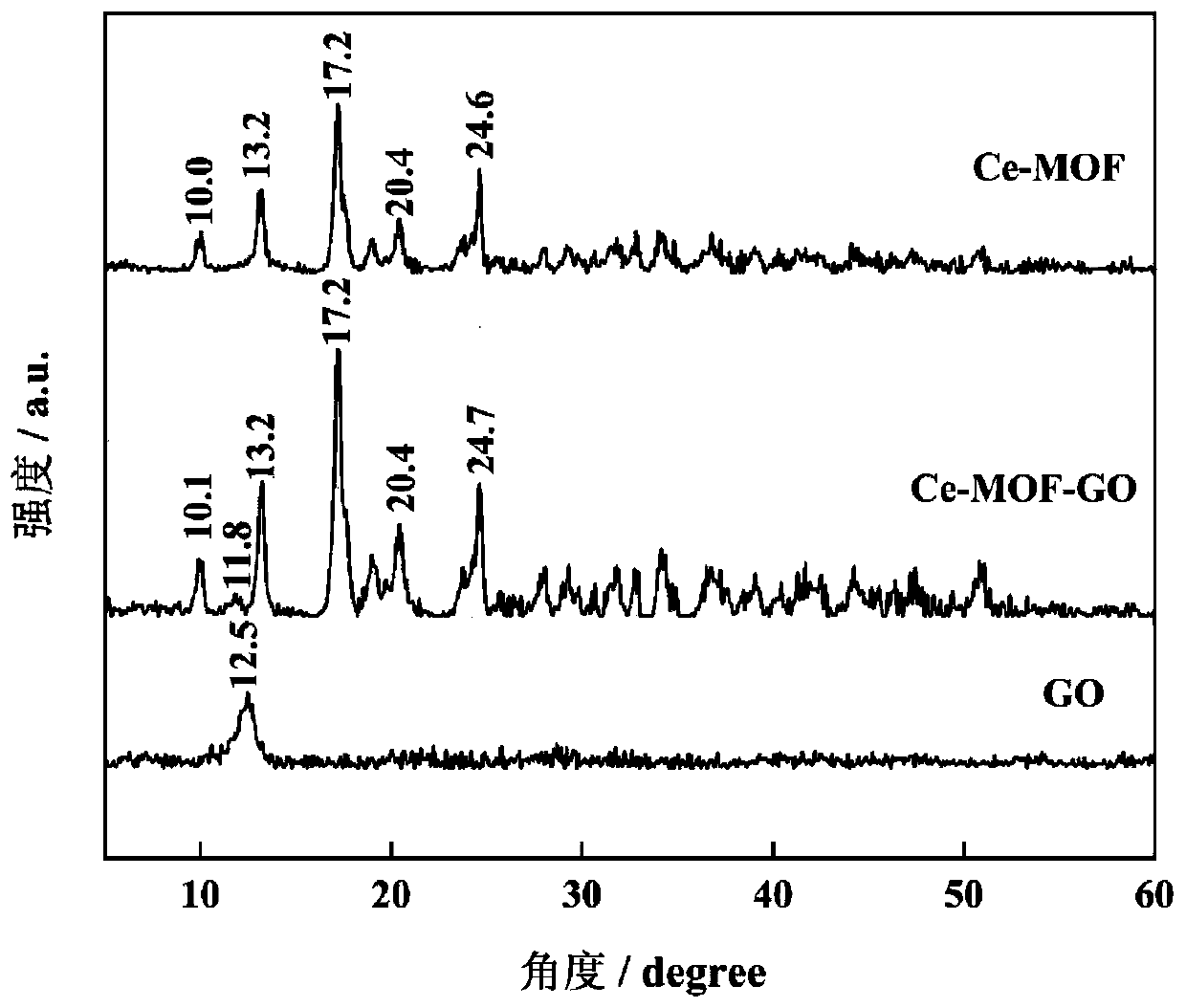

[0031] (1) Preparation of Ce-MOF-GO:

[0032] 3mg mL -1 The cerium-based metal-organic framework and 0.2mg mL -1 Graphene oxide was dispersed in water at the same time, and ultrasonically prepared to prepare a cerium-based metal-organic framework / graphene oxide composite dispersion, and then take 5 μL of the above-mentioned cerium-based metal-organic framework / graphene oxide composite dispersion and apply it on the surface of a glassy carbon electrode to prepare Ce-MOF-GO nanocomposite modified materials.

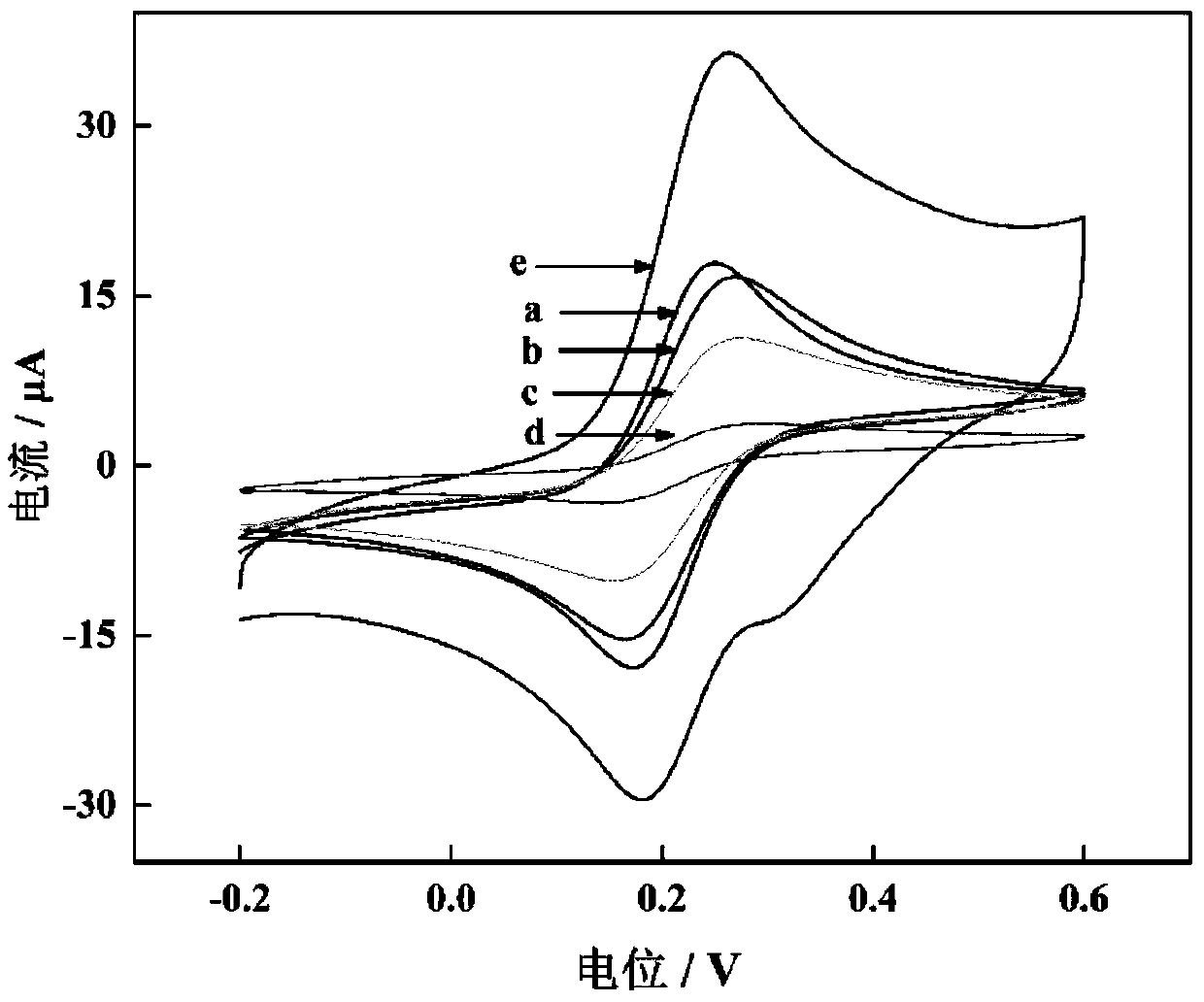

[0033] (2) Preparation of Ce-MOF-ERGO:

[0034]Use the method of electrochemical reduction to scan the cyclic voltammetry curve in 0.05mol / L PBS buffer solution (pH=5.0) for 10 circles, and generate graphene oxide into electroreduced graphene oxide, wherein the scanning range is -0.6V~-1.2 V, the scan rate is 0.02v / s. After rinsing the surface of the electrode with ultrapure water and drying at room temperature, the electrochemical sensor of the cerium-based metal-organ...

Embodiment 2

[0052] (1) Preparation of Ce-MOF-GO:

[0053] 0.5mg mL -1 The cerium-based metal-organic framework and 0.1mg mL -1 Graphene oxide is dispersed in water at the same time, and ultrasonically prepared to prepare a cerium-based metal-organic framework / graphene oxide composite dispersion, and then take 10 μL of the above-mentioned cerium-based metal-organic framework / graphene oxide composite dispersion and apply it on the surface of a glassy carbon electrode to prepare Ce-MOF-GO nanocomposite modified materials.

[0054] (2) Preparation of Ce-MOF-ERGO:

[0055]Use the method of electrochemical reduction to scan the cyclic voltammetry curve in 0.05mol / L PBS buffer solution (pH=5.0) for 10 circles, and generate graphene oxide into electroreduced graphene oxide, wherein the scanning range is -0.6V~-1.2 V, the scan rate is 0.02v / s. After rinsing the surface of the electrode with ultrapure water and drying at room temperature, the electrochemical sensor of the cerium-based metal-org...

Embodiment 3

[0058] (1) Preparation of Ce-MOF-GO:

[0059] 4mg mL -1 The cerium-based metal-organic framework and 0.5mg mL -1 Graphene oxide is dispersed in water at the same time, and ultrasonically prepared to prepare a cerium-based metal-organic framework / graphene oxide composite dispersion, and then take 2 μL of the above-mentioned cerium-based metal-organic framework / graphene oxide composite dispersion and apply it on the surface of a glassy carbon electrode to prepare Ce-MOF-GO nanocomposite modified materials.

[0060] (2) Preparation of Ce-MOF-ERGO:

[0061] Use the method of electrochemical reduction to scan the cyclic voltammetry curve in 0.05mol / L PBS buffer solution (pH=5.0) for 10 circles, and generate graphene oxide into electroreduced graphene oxide, wherein the scanning range is -0.6V~-1.2 V, the scan rate is 0.02v / s. After rinsing the surface of the electrode with ultrapure water and drying at room temperature, the electrochemical sensor of the cerium-based metal-organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com