Dark color reflective heat insulation paint and preparation method thereof

A technology of reflective heat insulation coatings and dark colors, which is applied in the direction of reflection/signal coatings, multi-color effect coatings, antifouling/underwater coatings, etc. It can solve the problems of poor reflective heat insulation performance, failure to meet market demand, and insufficient color richness, etc. problems, achieve good reflection and heat insulation effects, meet decorative needs, and have rich colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

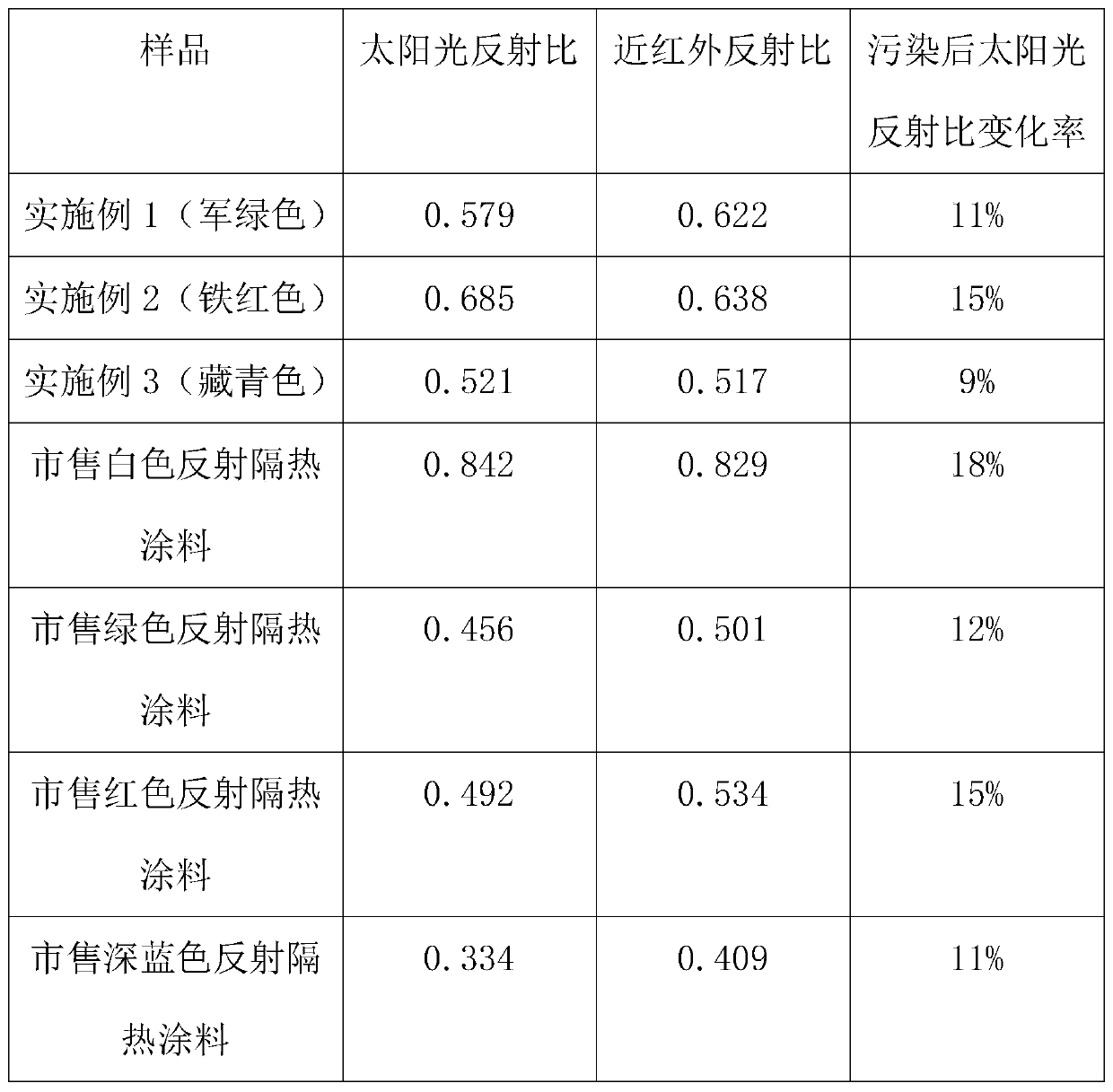

Examples

Embodiment 1

[0023] The water-based acrylic resin uses 35% pure acrylic emulsion (Zhengzhou Yuanding Chemical DR-60), 8% heat-reflecting polymer, 2% cellulose ether, 12% superfine heat-insulating powder, 8% hollow glass beads, 4% high refractive index pigment, 0.5% hydrophobic modified ammonium salt dispersant, 1% thick build defoamer, 1% non-ionic wetting agent, 1% antifreeze, 1% film forming agent, antiseptic 0.5%, the balance is water. The heat reflective polymer is composed of 40% acrylic polymer, 30% rutile titanium dioxide, 10% magnesium silicate and 20% water. To prepare army green reflective heat insulation coating, the dosage of high refractive index pigment is iron yellow: phthalocyanine blue = 9:8.

Embodiment 2

[0025] The water-based acrylic resin uses 50% pure acrylic emulsion (Zhengzhou Yuanding Chemical DR-60), 6% heat-reflecting polymer, 1% cellulose ether, 15% superfine heat-insulating powder, 10% hollow glass beads, High refractive index pigment 10%, hydrophobic modified ammonium salt dispersant 1%, thick build defoamer 1%, non-ionic wetting agent 1%, antifreeze agent 0.5%, film forming agent 0.5%, preservative 0.5%, the balance is water. The heat reflective polymer is composed of 50% acrylic polymer, 25% rutile titanium dioxide, 15% magnesium silicate and 10% water. To prepare iron red reflective heat insulation paint, only iron red is used as high refractive index pigment.

Embodiment 3

[0027] The water-based acrylic resin is made of pure acrylic emulsion (Zhengzhou Yuanding Chemical DR-60) 40%, heat-reflecting polymer 7%, cellulose ether 1.5%, heat-insulating filler 10% of ultra-fine heat-insulating powder, hollow glass beads 9%, 8% high refractive index pigment, 0.5% hydrophobic modified ammonium salt dispersant, 1% thick build defoamer, 1% non-ionic wetting agent, 0.5% antifreeze, 0.5% film forming agent, preservative 0.5%, the balance is water. The heat reflective polymer is composed of 55% acrylic polymer, 10% rutile titanium dioxide, 20% magnesium silicate and 15% water. To prepare navy blue reflective heat insulation coating, the dosage of high refractive index pigment is iron yellow: iron red: phthalocyanine blue = 5:8:10.

[0028] Prepare the proportions of Example 1, Example 2 and Example 3 with the same preparation method, specifically: add water and cellulose ether to the stirring tank according to their respective mass fractions, and stir at a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com