NiO/C@NiFeLDH composite material and preparation method and application thereof

A composite material and reaction technology, applied in the field of electrochemistry, can solve the problems of high cost and material hindering practical application, and achieve the effects of easy control, good electrochemical catalytic activity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

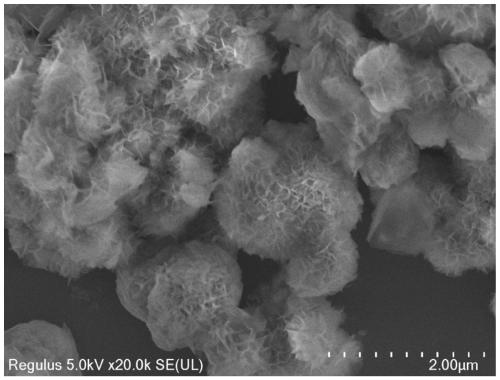

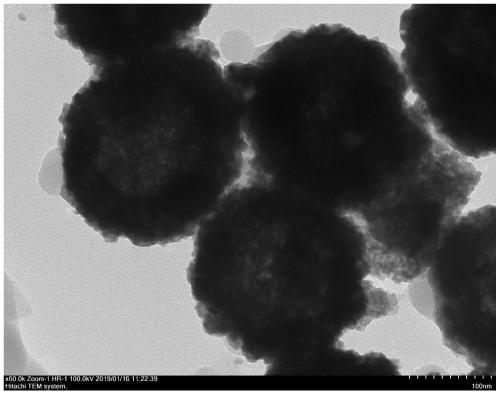

[0025] The invention provides a method for preparing a NiO / C@NiFeLDH composite material, comprising the following steps: (1) calcining the Ni-MOF precursor in an inert atmosphere to obtain carbon-containing nickel oxide; (2) oxidizing the carbon-containing Nickel is mixed and contacted in the first solvent containing surfactant to obtain functionalized carbon-containing nickel oxide; (3) disperse functionalized carbon-containing nickel oxide, nickel salt, iron source, urea, and trisodium citrate in In the second solvent, the heating reaction is carried out again.

[0026] Through the above technical scheme, the present invention has prepared NiO / C@NiFeLDH composite material, which can be used as an oxygen evolution reaction catalyst and has better electrochemical catalytic activity. Compared with commercial RuO 2 There is a smaller overpotential, and the Tafel slope is also lower than that of commercial RuO 2 , while being cheaper. Moreover, the preparation method of the pre...

preparation example

[0052] Prepared according to the method described in the literature: Shujin Hou Xingtao Xu Miao Wang Yingqiao Xu Ting Lu YefengYao and Likun Pan* "Carbon-incorporated Janus-type Ni2P / Ni hollow spheres for high performance hybrid supercapacitors" J.Mater.Chem.A 2017 519054. Ni-MOFs:

[0053] 864mg Ni(NO 3 ) 2 6H2O, 300mg trimesic acid (BTC) and 3.0g polyvinylpyrrolidone, Mw=40000) were dissolved in N,N-dimethylformamide (20mL ), ethanol (20 mL) and water (20 mL), stirred magnetically for 3 hours. The obtained homogeneous green solution was poured into a 100 mL polytetrafluoroethylene-lined stainless steel autoclave and reacted in an oven at 150 °C for 10 hours. After the autoclave was naturally cooled to room temperature, the solid product was centrifuged at 6000 rpm for 5 minutes, washed with and ethanol three times, and then dried in an oven at 60 °C overnight.

Embodiment 1

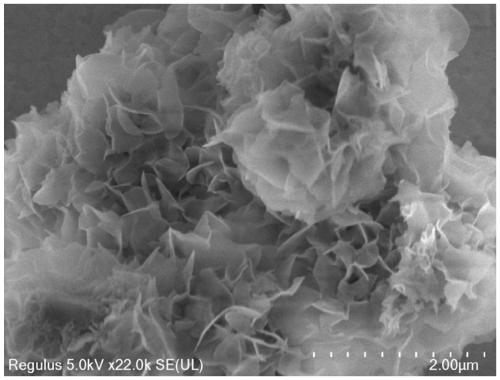

[0055] 1) The Ni-MOF prepared in the preparation example was calcined at 800° C. for 3 h in a nitrogen atmosphere, and the heating and cooling rates were both 3° C. / min to obtain NiO / C.

[0056] 2) 3g of PVP (polyvinylpyrrolidone) was dispersed in 15ml of ethanol, and then 50mg of NiO / C was added, stirred at room temperature (20°C) for 12h and centrifuged to dry to obtain functionalized NiO / C.

[0057] 3) Add 50 mg of functionalized NiO / C that has been dried by centrifugation into 34 ml of water, and sonicate for 1 h. Add 0.05mmol Ni(NO 3 ) 2 ·6H 2 O, 0.02mmol Fe(NO 3 ) 3 9H 2 O, 0.02mmol urea and 0.01mmol Na 3 C 6 h 5 o 7 2H 2 O, ultrasound 1h.

[0058] Hydrothermal treatment was carried out in an autoclave at 140 °C for 26 hours. After cooling the solution to room temperature, the product was washed with distilled water and ethanol, and then dried at 60 °C overnight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com