Molybdenum doped vanadium disulfide micron flower material and preparation method and application thereof

A technology of vanadium disulfide and micron flowers, applied in the field of electrocatalytic materials, can solve the problem of low electrocatalytic hydrogen evolution activity, achieve high electrocatalytic hydrogen evolution activity, good catalytic activity, and improve electrocatalytic hydrogen evolution activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 0.2106g of ammonium metavanadate, 2mL of ammonia water, and 0.0392g of ammonium molybdate, add them to 35mL of deionized water, and stir magnetically at a stirring speed of 200r / min to dissolve them into a transparent solution; then weigh 1.5026g Add thioacetamide to the above clear solution, and continue stirring to completely dissolve it into a light yellow solution. Pour the above light yellow solution into a polytetrafluoroethylene liner and seal it, then put the polytetrafluoroethylene liner into a stainless steel reaction kettle and tighten it, and then place it in an oven at 160°C for 24 hours. After naturally cooling to room temperature, the obtained product was washed successively with absolute ethanol and deoxygenated deionized water; then it was frozen in a refrigerator for 12 hours, and then placed in a freeze dryer at -50°C for 30 hours in vacuum to obtain molybdenum doped Heterogeneous vanadium disulfide micron flower material.

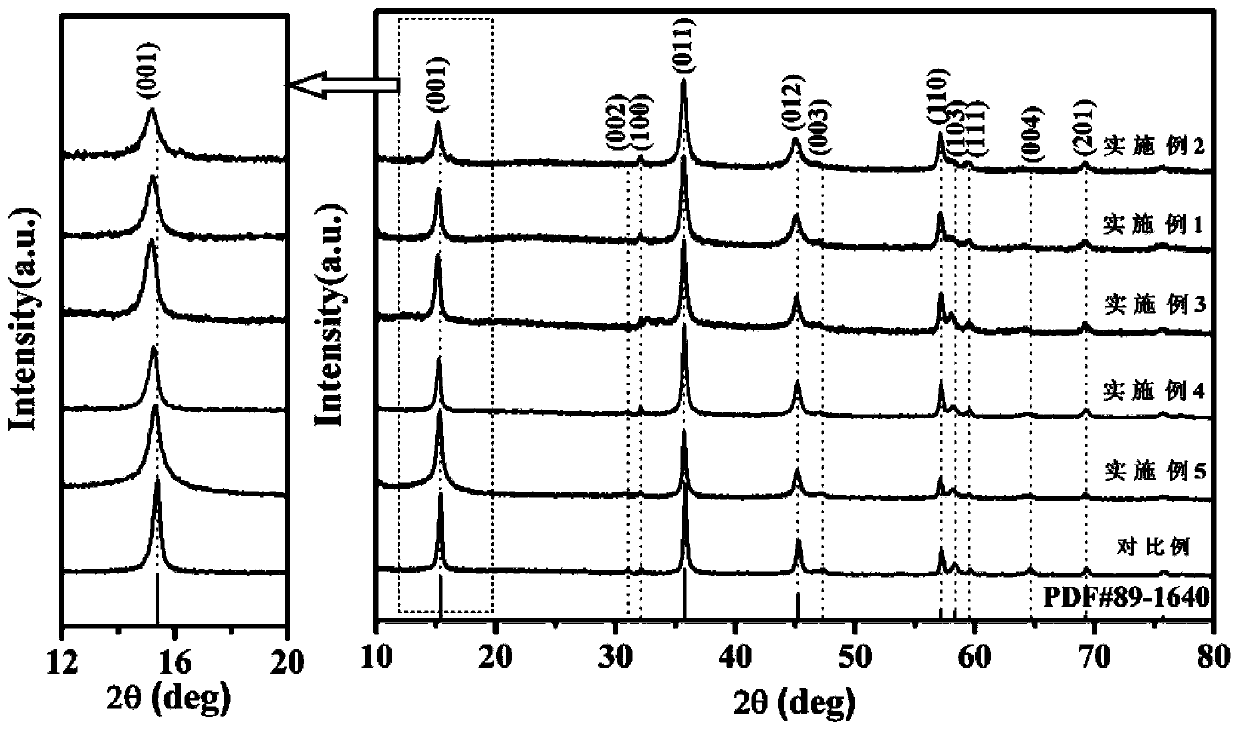

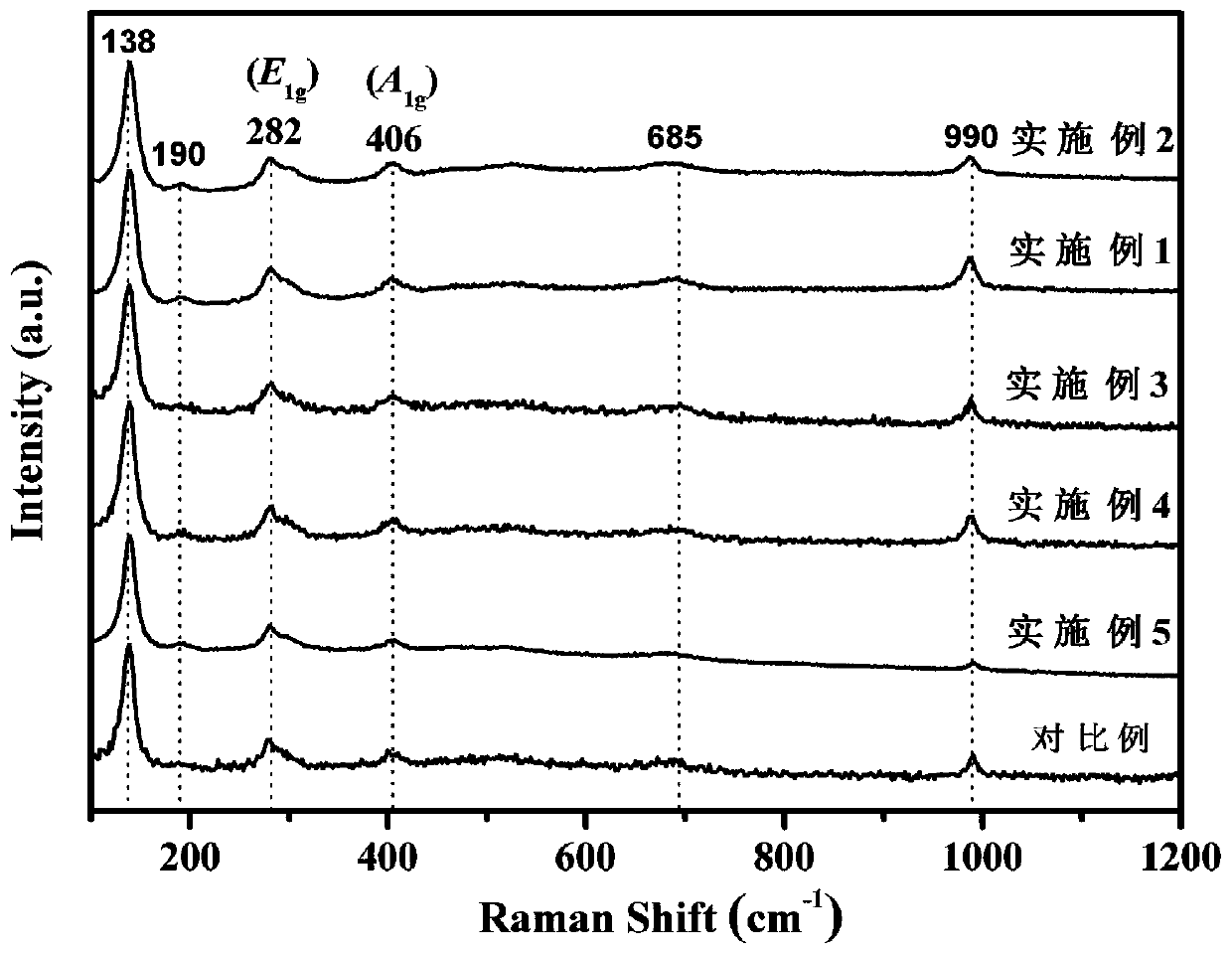

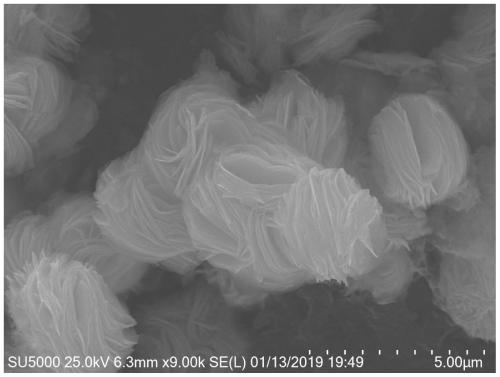

[0036]Use X-ray dif...

Embodiment 2

[0039] Weigh 0.1989g of ammonium metavanadate, 2mL of ammonia water, and 0.0588g of ammonium molybdate, add them to 35mL of deionized water successively, and perform magnetic stirring at a stirring speed of 200r / min to dissolve them into a transparent solution; then weigh 1.5026g Add thioacetamide to the above clear solution, and continue stirring to completely dissolve it into a light yellow solution. Pour the above light yellow solution into a polytetrafluoroethylene liner and seal it, then put the polytetrafluoroethylene liner into a stainless steel reaction kettle and tighten it, and then place it in an oven at 160°C for 24 hours. After naturally cooling to room temperature, the obtained product was washed successively with absolute ethanol and deoxygenated deionized water; then it was frozen in a refrigerator for 12 hours, and then placed in a freeze dryer at -50°C for 30 hours in vacuum to obtain molybdenum doped Heterogeneous vanadium disulfide micron flower material. ...

Embodiment 3

[0043] Weigh 0.2223g of ammonium metavanadate, 2mL of ammonia water, and 0.0196g of ammonium molybdate, add them to 35mL of deionized water successively, and perform magnetic stirring at a stirring speed of 200r / min to dissolve them into a transparent solution; then weigh 1.5026g Add thioacetamide to the above clear solution, and continue stirring to completely dissolve it into a light yellow solution. Pour the above light yellow solution into a polytetrafluoroethylene liner and seal it, then put the polytetrafluoroethylene liner into a stainless steel reaction kettle and tighten it, and then place it in an oven at 160°C for 24 hours. After naturally cooling to room temperature, the obtained product was washed successively with absolute ethanol and oxygen-depleted deionized water; then it was placed in a vacuum drying oven at 60° C. for 24 hours in vacuum to obtain molybdenum-doped vanadium disulfide micron flower material.

[0044] Use XRD and Raman to characterize the struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com