Preparation method of high-compactness small-diameter spherical tricobalt tetraoxide

A technology of tricobalt tetroxide and small particle size, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems that the sphericity and compactness cannot meet the battery capacity, the precipitation treatment of unfavorable metal ions, the high content of Co in the mother liquor and the tail liquor, and reduce heavy metals. The effect of high content, product tap density and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

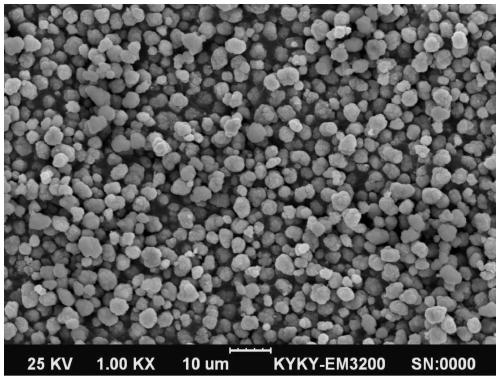

Image

Examples

Embodiment 1

[0025] Provide cobalt sulfate solution from the extraction process, generally choose to use cobalt-containing complexes to produce 1.6mol / L cobalt sulfate solution through wet treatment;

[0026] Alkali preparation: Weigh 3 kg of sodium hydroxide crystals, add deionized water to dissolve, and finally set the volume to 10L. In order to prepare enough lye, the above steps can be repeated;

[0027] Ammonia water configuration: Measure 1.6L of 25%-27% ammonia water, add water to dilute, and finally set the volume to 10L. In order to prepare enough ammonia water, the above steps can be repeated;

[0028] Add 10L of hot pure water to the reaction kettle, adjust the pH to 12 by adding the lye configured above, and then pass in compressed air with an air flow rate of 25L / h, and pump the cobalt sulfate solution, lye solution and ammonia solution configured above at the same time , wherein the flow rate of cobalt liquid is 20mL / min, the flow rate of ammonia water is 2ml / min, and the sti...

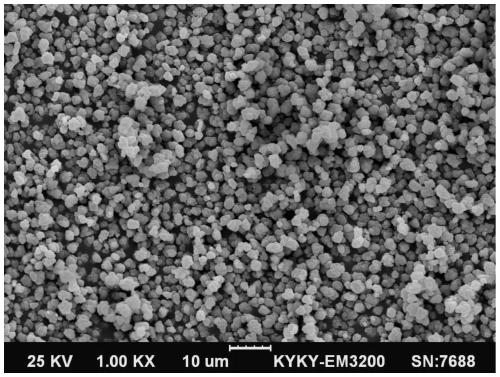

Embodiment 2

[0033] Provide cobalt sulfate solution from the extraction process, generally choose to use cobalt-containing complexes to produce 1.6mol / L cobalt sulfate solution through wet treatment;

[0034] Alkali preparation: Weigh 3 kg of sodium hydroxide crystals, add deionized water to dissolve, and finally set the volume to 10L. In order to prepare enough lye, the above steps can be repeated;

[0035] Ammonia water configuration: Measure 1.6L of 25%-27% ammonia water, add water to dilute, and finally set the volume to 10L. In order to prepare enough ammonia water, the above steps can be repeated;

[0036] Add 2L of hot pure water into the reaction kettle, adjust the pH to 12 by adding the lye configured above, and then pass in compressed air with an air flow rate of 25L / h, and pump the cobalt sulfate solution, lye solution and ammonia solution in the above steps at the same time, Among them, the cobalt liquid flow rate is 16mL / min, the ammonia water flow rate is 1.5ml / min, and the s...

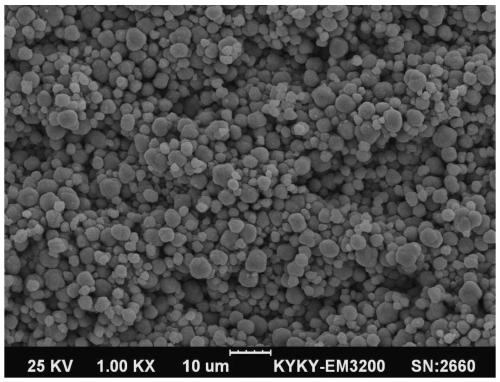

Embodiment 3

[0041] Provide cobalt sulfate solution from the extraction process, generally choose to use cobalt-containing complexes to produce 1.6mol / L cobalt sulfate solution through wet treatment;

[0042] Alkali preparation: Weigh 3 kg of sodium hydroxide crystals, add deionized water to dissolve, and finally set the volume to 10L. In order to prepare enough lye, the above steps can be repeated;

[0043] Ammonia water configuration: Measure 1.6L of 25%-27% ammonia water, add water to dilute, and finally set the volume to 10L. In order to prepare enough ammonia water, the above steps can be repeated;

[0044] Add 10L of hot pure water into the reaction kettle, adjust the pH to 12 by adding the lye configured above, and then pass in compressed air with an air flow rate of 25L / h, and pump the cobalt sulfate solution, lye solution and ammonia solution in the above steps at the same time, Among them, the flow rate of cobalt liquid is 16mL / min, the flow rate of ammonia water is 1.5ml / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com