Preparation method of thiamine mononitrate

A technology of thiamine nitrate and thiamine sulfate, which is applied in the field of chemical engineering, can solve the problems of time and manpower consumption, potential safety hazards, cumbersome steps, etc., and achieve the effects of reducing energy consumption and production costs, avoiding danger, and simple operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

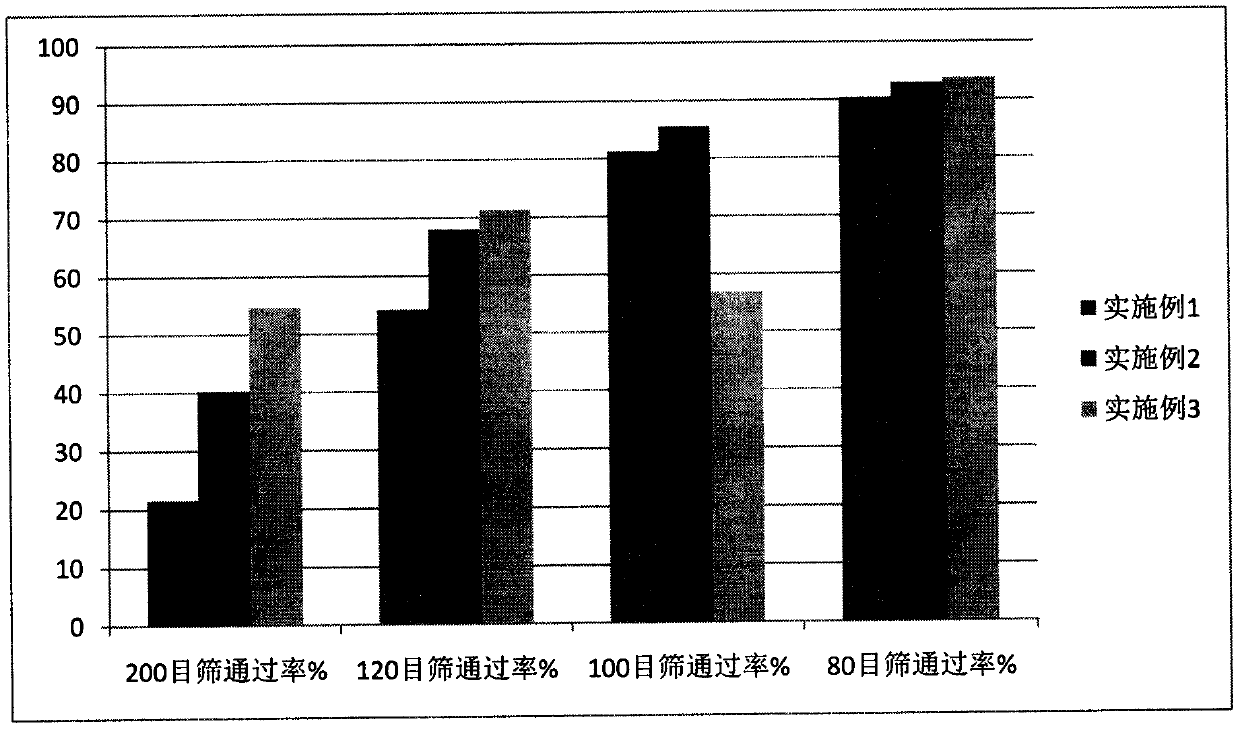

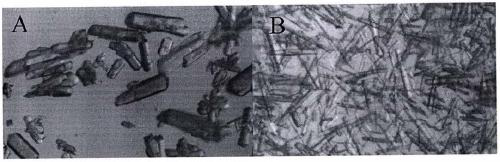

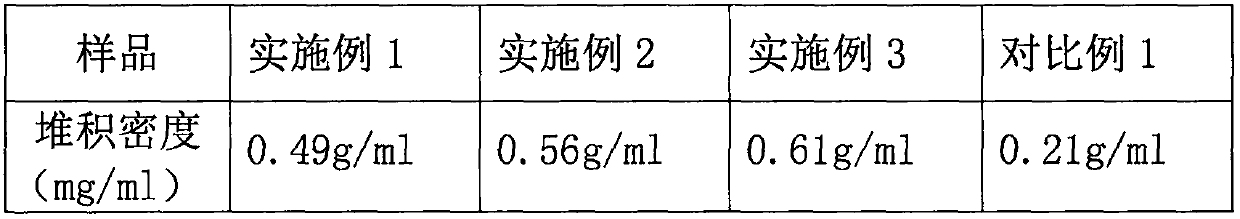

Embodiment 1

[0040] Embodiment 1: a kind of preparation method of thiamine nitrate comprises following processing steps:

[0041] S1. Thoroughly mix 25 g of thiothiamine with 26 g of 35% hydrogen peroxide; adjust the pH of the solution to 4 with 0.5 g of 1% sulfuric acid, and control the oxidation temperature at 10-16°C. Add 1.75g of activated carbon for decolorization, the decolorization temperature is 23°C, stir for 1h, and filter with suction to obtain thiamine sulfate;

[0042] S2. Fully mix 75.65 g of thiamine sulfate and 3.45 g of nitric acid with a mass fraction of 65% according to a mass ratio of 22:1; add the nitric acid at one time, and control the temperature below 10°C. The stirring speed is 112r / min;

[0043] S3. Use a peristaltic pump to slowly add ammonia water. The rotation speed of the peristaltic pump is 0.1-0.7 rpm. Add ammonia water with a mass fraction of 16.57% to the mixed solution of thiamine sulfate and nitric acid, and adjust the pH value of the mixed solution ...

Embodiment 2

[0046] Embodiment 2: a kind of preparation method of thiamine nitrate comprises following processing steps:

[0047] S1. Thoroughly mix 25g of thiothiamine with 26g of 35% hydrogen peroxide; use 0.5g of 1% sulfuric acid to adjust the pH of the solution to 4, and control the oxidation temperature at 10-16°C. Add 1.75g of activated carbon for decolorization, the decolorization temperature is 23°C, stir for 1h, and filter with suction to obtain thiamine sulfate;

[0048] S2. Fully mix 75.65 g of thiamine sulfate and 3.45 g of nitric acid with a mass fraction of 65% according to a mass ratio of 22:1; add the nitric acid at one time, and control the temperature below 10°C. The stirring speed is 112r / min;

[0049] S3. Use a peristaltic pump to slowly add ammonia water. The speed of the peristaltic pump is 0.1-0.7 rpm. Add ammonia water with a mass fraction of 21.04% to the mixed solution of thiamine sulfate and nitric acid, and adjust the pH value of the mixed solution to about 7...

Embodiment 3

[0052] Embodiment 3: a kind of preparation method of thiamine nitrate comprises following processing steps:

[0053]S1. Thoroughly mix 25 g of thiothiamine with 26 g of 35% hydrogen peroxide; adjust the pH of the solution to 4 with 0.5 g of 1% sulfuric acid, and control the oxidation temperature at 10-16°C. Add 1.75g of activated carbon for decolorization, the decolorization temperature is 23°C, stir for 1h, and filter with suction to obtain thiamine sulfate;

[0054] S2. Fully mix 75.66 g of thiamine sulfate and 8.22 g of nitric acid with a mass fraction of 65% according to a mass ratio of 9:1; add the nitric acid at one time, and control the temperature below 10°C. The stirring speed is 112r / min;

[0055] S3. Use a peristaltic pump to slowly add ammonia water. The speed of the peristaltic pump is 0.1-0.7 rpm. Add ammonia water with a mass fraction of 21.04% to the mixed solution of thiamine sulfate and nitric acid, and adjust the pH value of the mixed solution to about 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com