Water glass-acrylate compound gel water shut-off agent and preparation method thereof

A technology of acrylate and composite gel, which is applied in the field of water glass-acrylate composite gel and its preparation, can solve the problems of poor durability, weak strength, high price and the like, and achieves a reasonable formula, simple operation and environment-friendly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

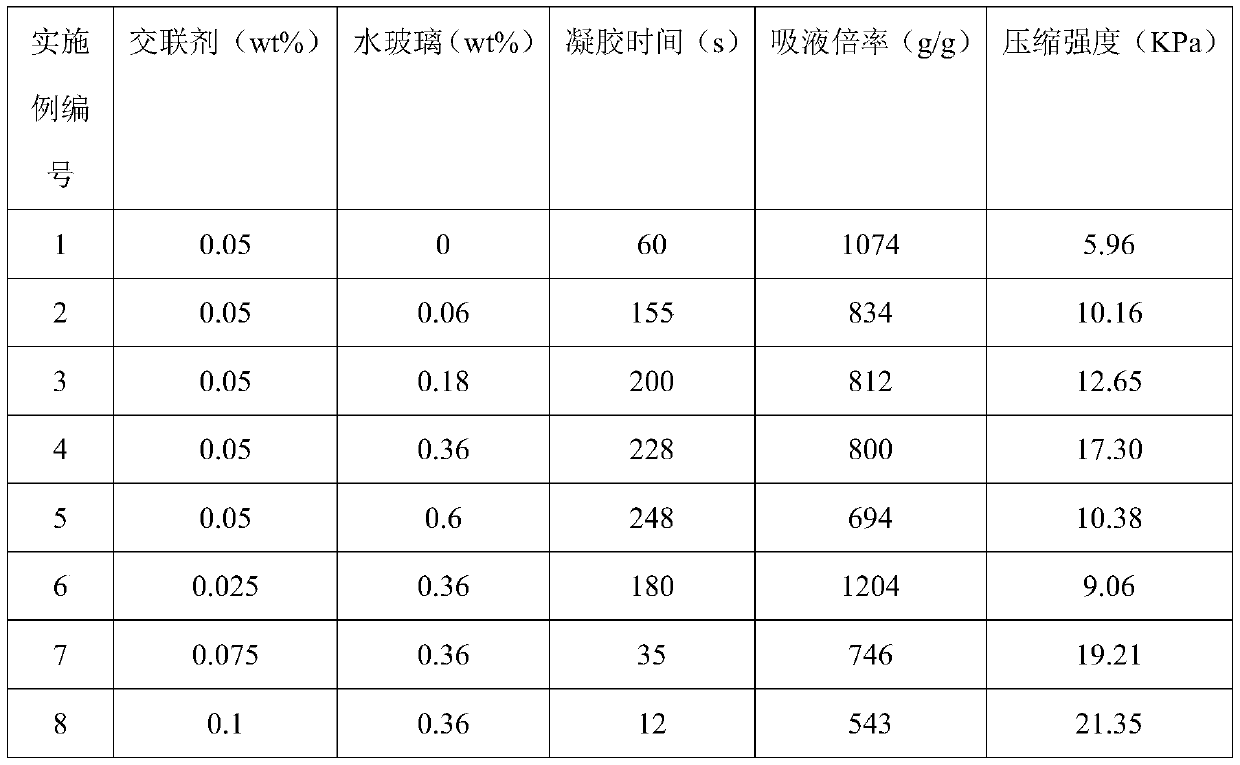

Embodiment 1

[0027] Step a: under stirring in an ice-water bath, metal sodium hydroxide (0.2mol / L) and water glass (40 ° Baume degree) are slowly added dropwise to acrylic acid, and the neutralization degree of acrylic acid is 60 mol%, wherein the water glass and acrylic acid The molar ratio is 0:1);

[0028] Step b: Stir the neutralized solution in step A for 10 hours at room temperature, add 0.05wt% N, N'-methylenebisacrylamide and 2wt% triethanolamine respectively, and stir evenly to prepare acrylate gel water blocking agent A slurry;

[0029] Step c: dissolving 0.2wt% potassium persulfate and 0.5wt% copper sulfate in distilled water to prepare B slurry of acrylate gel water blocking agent;

[0030] Step d: Pour the A slurry prepared in step b and the B slurry prepared in step c into the separating funnel respectively, and open the valve at the same time to quickly mix the A and B slurries, preferably the volume ratio of the A and B liquids is 1:1 . The gel coagulation time was recor...

Embodiment 2-5

[0032] Step a: Under stirring in an ice-water bath, metal hydroxide (0.2mol / L) and water glass (Baume degree 40°) of different mass fractions are slowly added dropwise to the acrylate to neutralize to a degree of 60mol%, wherein In embodiment 2, the mol ratio of water glass and acrylic acid is 0.06:1, embodiment 3 is 0.18:1, embodiment 4 is 0.36:1, embodiment 5 is 0.6:1);

[0033] Step b: Stir the neutralized solution in step A for 10 hours at room temperature, add 0.05wt% N,N'-methylenebisacrylamide and 2-wt% triethanolamine, and stir evenly to obtain a water glass-acrylate composite gel A slurry of glue water blocking agent;

[0034] Step c: dissolving 0.2wt% potassium persulfate and 0.5wt% copper sulfate in distilled water to prepare B slurry of water glass-acrylate composite gel water blocking agent;

[0035] Step d: Pour the A slurry prepared in step b and the B slurry prepared in step c into the separating funnel respectively, and open the valve at the same time to quic...

Embodiment 6-8

[0037] Step a: Under stirring in an ice-water bath, slowly add metal hydroxide (0.1-1mol / L) and water glass (Baume degree 40°) to the acrylate for neutralization until the neutralization degree is 40-80mol%. The molar ratio of glass to acrylic acid is 0.18:1);

[0038] Step b: Stir the neutralized solution in step A for 10 hours at room temperature, add different mass fractions of ethylene glycol diacrylate and 3wt% tetramethylethylenediamine, and stir evenly to obtain a water glass-acrylate composite gel plug A slurry of water agent (wherein the crosslinking agent content is 0.025% in embodiment 6, embodiment 7 is 0.075%, embodiment 8 is 0.1%);

[0039] Step c: dissolving 0.1wt% initiator and 0.2wt% auxiliary agent in distilled water to prepare B slurry of water glass-acrylate composite gel water blocking agent;

[0040] Step d: Pour the A slurry prepared in step b and the B slurry prepared in step c into the separating funnel respectively, and open the valve at the same tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com