Batched preparation method of interlayer in-situ polymerization of graphene/polymer foams

An in-situ polymerization and graphene technology, applied in the field of polymer composite materials, can solve the problems of pollution, cumbersome steps, high energy consumption, etc., and achieve safe and controllable time-consuming and energy-consuming, uniform product structure, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

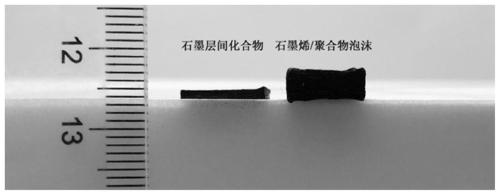

[0029] (1) Preparation of graphite intercalation compound: Mix 2 g of ferric chloride with 100 mL of concentrated sulfuric acid and add 5 g of natural graphite flakes. After standing for 6 h, the solid part is separated by suction filtration and washed with 1 mol / L dilute sulfuric acid.

[0030] (2) Interlayer in-situ polymerization of monomers: add the graphite interlayer compound obtained in step (1) into a 0.1 mol / L pyrrole sulfuric acid solution (100 mL), and react at 0-5° C. for 24 h.

[0031] (3) Cleaning and drying of the product: the solid part was separated by suction filtration, and the product was washed alternately with water and alcohol for 5 times, and then dried in a blast oven at 60° C. to obtain a graphene / polypyrrole porous foam.

[0032] (4) The electrical conductivity of the obtained graphene / polypyrrole porous foam reaches 130 S / cm.

Embodiment 2

[0034] (1) Preparation of graphite intercalation compound: Mix 2 g of potassium persulfate with 100 mL of concentrated sulfuric acid and add a piece of flexible graphite paper with a mass of 3 g. After standing for 24 hours, take out the graphite paper and rinse it with 1 mol / L dilute sulfuric acid.

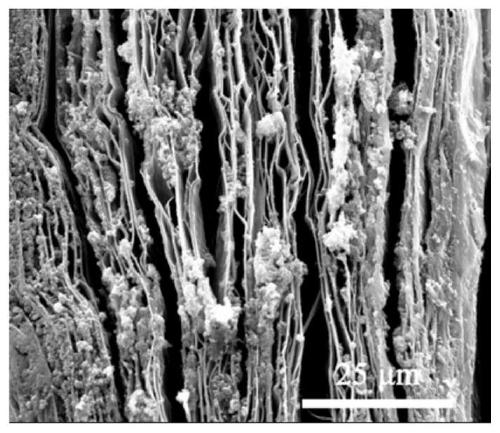

[0035] (2) Interlayer in-situ polymerization of monomers: the graphite paper obtained in step (1) was placed in 0.05 mol / L dopamine aqueous solution (100 mL), and reacted at room temperature for 4 h.

[0036] (3) Cleaning and drying of the product: the graphite paper is taken out from the reaction solution in step (2), washed alternately with water and alcohol, and then dried in a blast oven at 40°C to obtain a graphene / polydopamine foam.

[0037] (4) gained graphene / polydopamine foam is right to Pb 2+ 、Cd 2+ and Cu 2+ The adsorption values of heavy metal ions are 163.0mg / g, 103.5mg / g and 89.6mg / g respectively

Embodiment 3

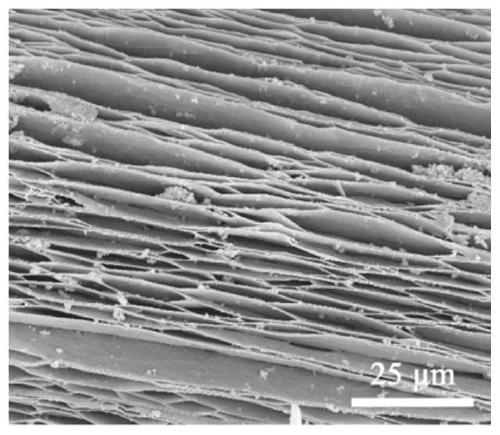

[0039] (1) Preparation of graphite interlayer compound: Slowly mix 15g of potassium ferrate with 100mL of concentrated sulfuric acid in an ice bath and add a piece of 2g of highly oriented pyrolytic graphite. dilute sulfuric acid rinse.

[0040] (2) Interlayer in-situ polymerization of monomers: the highly oriented pyrolytic graphite obtained in step (1) was placed in 0.1 mol / L polyaniline hydrochloric acid solution (100 mL), and reacted at room temperature for 24 h.

[0041] (3) Cleaning and drying of the product: take out the highly oriented pyrolytic graphite from the reaction solution in step (2), wash it alternately with water and alcohol, and dry it in a blast oven at 60°C to obtain a graphene / polyaniline foam .

[0042] (4) The electrical conductivity of the obtained graphene / polyaniline porous foam reaches 1120 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com