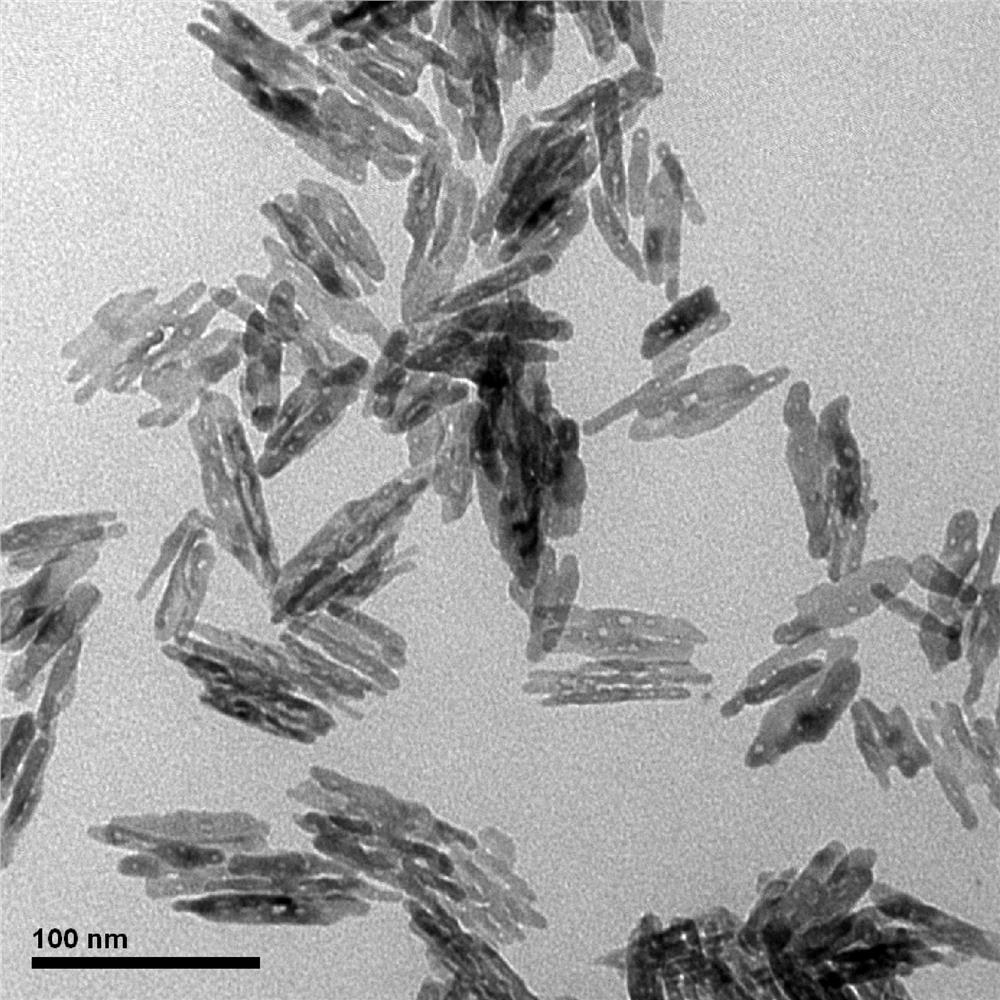

A kind of nano transparent iron oxide ink-jet color paste and preparation method thereof

A technology of transparent iron oxide and iron oxide, applied in the direction of pigment slurry, etc., can solve the problems of unreachable inkjet, air pollution, and inapplicability, and achieve good dispersion effect and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

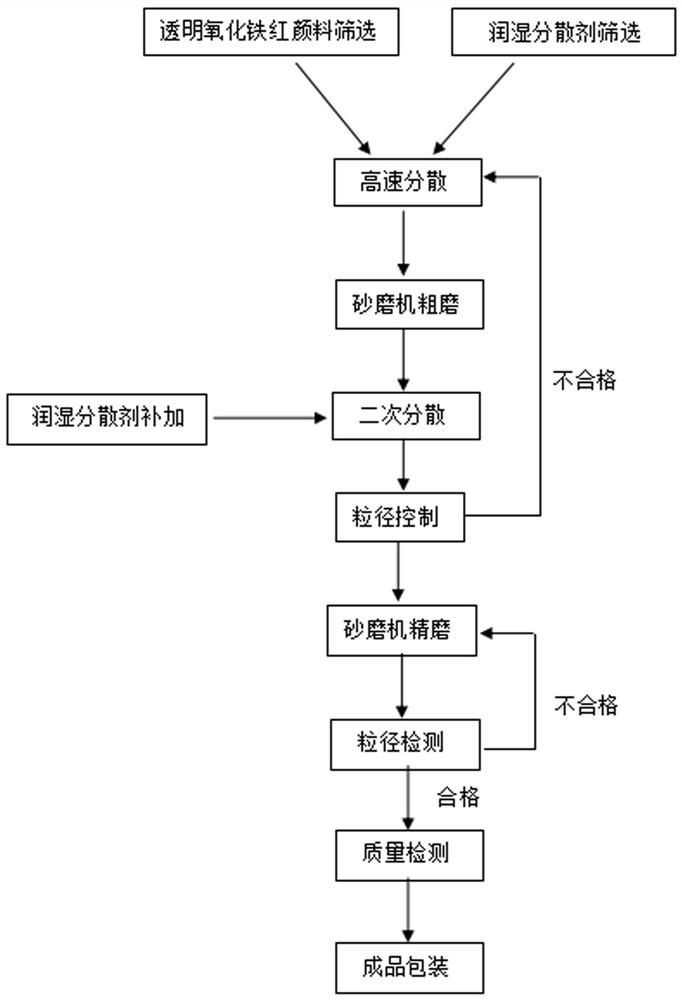

Method used

Image

Examples

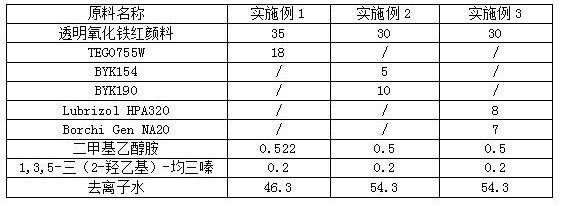

Embodiment 1

[0041] According to the weight ratio in Table 1, add 38.3% deionized water, 0.2% 1,3,5-tris(2-hydroxyethyl)-s-triazine, pH regulator I 0.3% dimethylethanolamine, dispersant I 15% TEGO755W After stirring evenly at a speed of 600r / min in a high-speed disperser, add 35% transparent iron oxide red pigment powder, disperse at a high speed of 800r / min for 60 minutes, and then use a pump to transport the slurry to a horizontal sand mill for further processing. Coarse grinding, using 0.6 zirconium beads as the grinding medium, grinding until the particle size of the color paste measured by the fineness scraper meter is less than 5um, pump the semi-finished color paste to the dispersion tank, add the remaining dispersant II 3% TEGO755W, in the high-speed disperser After re-dispersing for 60 minutes at a speed of 800r / min, use a pump to transport the color paste to a pin-pin horizontal sand mill for fine grinding. At this time, use 0.3um zirconium beads as the grinding medium, and grind ...

Embodiment 2

[0043] According to the weight ratio in Table 1, add 46.3% deionized water, 0.2% 1,3,5-tris(2-hydroxyethyl)-s-triazine, pH regulator I 0.3% dimethylethanolamine, dispersant I 5% BYK154 and 7% BYK190 mixture, after stirring evenly at a speed of 700r / min in a high-speed disperser, add 30% transparent iron oxide red pigment powder, disperse at a high speed of 700r / min for 75min, and use a pump to transport the slurry to a horizontal Coarsely grind in a sand mill, use 0.7 zirconium beads as the grinding medium, grind until the particle size of the color paste measured by the fineness scraper is less than 5um, pump the semi-finished color paste to the dispersion tank, add dispersant II 3% BYK190, After re-dispersing for 75 minutes at a speed of 1000r / min in a high-speed disperser, use a pump to transport the color paste to a pin-pin horizontal sand mill for fine grinding. At this time, use 0.3um zirconium beads as the grinding medium and grind until After the particle size of the c...

Embodiment 3

[0045] According to the weight ratio in Table 1, add 46.3% deionized water, 0.2% 1,3,5-tris(2-hydroxyethyl)-s-triazine, pH regulator I 0.3% dimethylethanolamine, dispersant I 5% Lubrizol The mixture of HPA320 and 7% Borchi Gen NA20 is stirred evenly in a high-speed disperser at a speed of 800r / min, then 30% transparent iron oxide red pigment powder is added, dispersed at a high speed of 800r / min for 90min, and the slurry is transported by a pump Go to a horizontal sand mill for coarse grinding, using 0.8 zirconium beads as the grinding medium, and grind until the particle size of the color paste measured by the fineness scraper is less than 5um, then pump the semi-finished color paste to the dispersion tank, and add dispersant Ⅱ3 %Lubrizol HPA320, after re-dispersing for 90 minutes at a speed of 1100r / min in a high-speed disperser, use a pump to transport the slurry to a pin-type horizontal sand mill for fine grinding, at this time use 0.3um zirconium beads as grinding Medium,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com