BaZrS3 thin film and preparation method and application thereof

A thin-film, S21 technology, applied in the field of materials, can solve the problems of unsuitability for photovoltaic applications, increase the band gap, poor thermodynamic stability, etc., and achieve the effects of excellent visible light absorption capacity and great application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

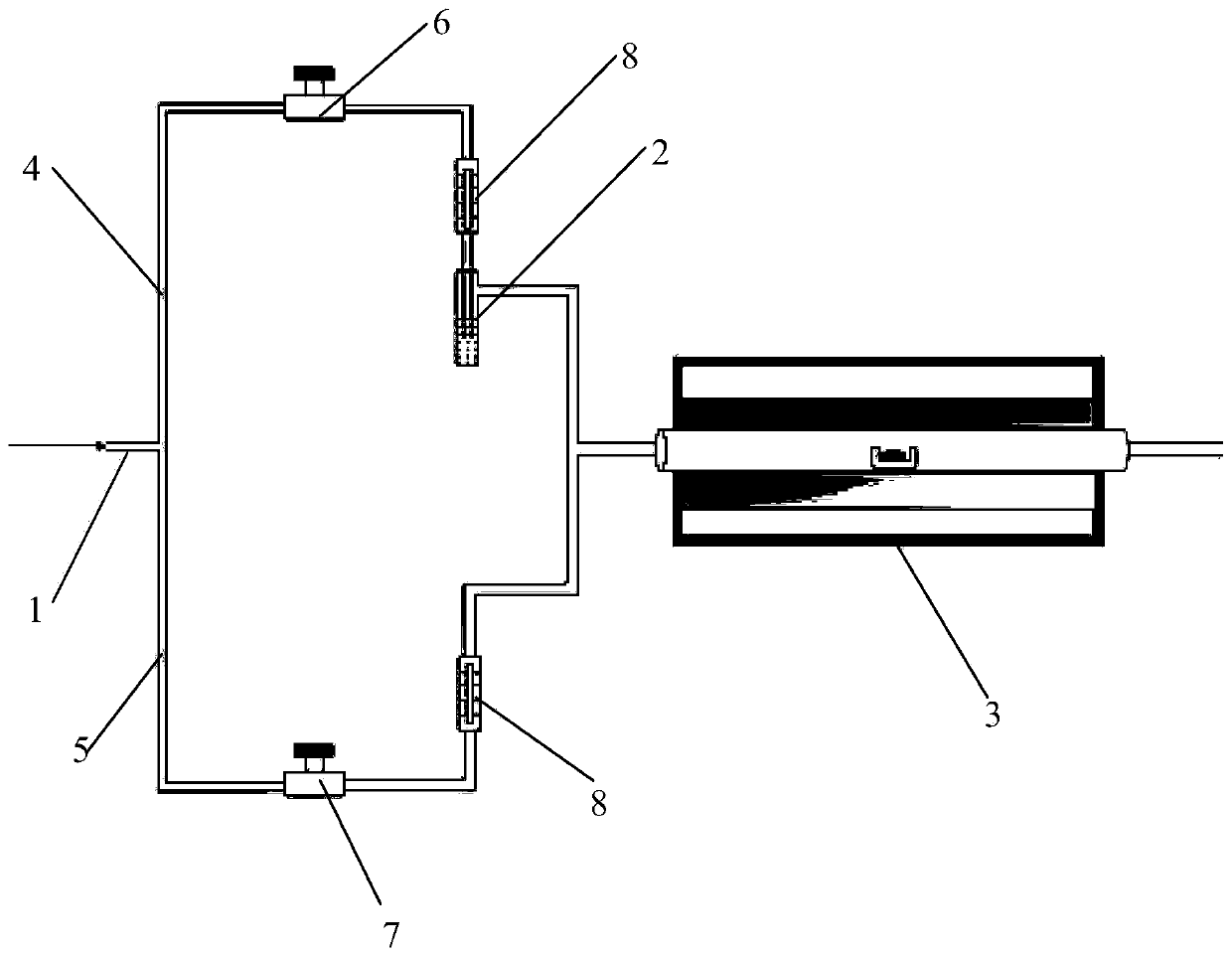

[0057] 1. BaZrO 3 The powder is placed in the chemical vapor deposition furnace, the second gas valve is opened, argon is introduced until the oxygen in the furnace is evacuated, and the chemical vapor deposition furnace is heated to 1100°C;

[0058] 2. Close the second gas valve and open the first gas valve, and pass the argon gas into the 2 In the cold trap of the solution, keep warm;

[0059] 3. When the temperature in the furnace drops to 800°C, close the first gas valve and open the second gas valve, and let the argon flow into the chemical vapor deposition furnace until the temperature in the furnace drops to room temperature.

[0060] 4. Take out the product processed in the previous step, and clean it with acetone and alcohol; ball mill, the ball milling speed is 450r / min, and the ball milling time is 3h; dry, the drying time is 2h; granulate, add an appropriate amount of PVA during granulation; Tablets, the tableting pressure is 30Mpa, and the diameter of the tablet...

Embodiment 2

[0064] 1. BaZrO 3 The powder is placed in the chemical vapor deposition furnace, the second gas valve is opened, argon gas is introduced until the oxygen in the furnace is evacuated, and the chemical vapor deposition furnace is heated to 1000°C;

[0065] 2. Close the second gas valve and open the first gas valve, and pass the argon gas into the 2 In the cold trap of S gas, keep warm;

[0066] 3. When the temperature in the furnace drops to 800°C, close the first gas valve and open the second gas valve, and let the argon flow into the chemical vapor deposition furnace until the temperature in the furnace drops to room temperature.

[0067] 4. Take out the product processed in the previous step, and clean it with acetone and alcohol; ball mill, the ball milling speed is 450r / min, and the ball milling time is 3h; dry, the drying time is 2h; granulate, add an appropriate amount of PVA during granulation; Tablets, the tableting pressure is 30Mpa, and the diameter of the tableting...

Embodiment 3

[0071] 1. BaZrO 3 The powder is placed in the chemical vapor deposition furnace, the second gas valve is opened, argon gas is introduced until the oxygen in the furnace is exhausted, and the chemical vapor deposition furnace is heated to 800°C;

[0072] 2. Close the second gas valve and open the first gas valve, and pass the argon gas into the 2 In the cold trap of the solution, keep warm;

[0073] 3. When the temperature in the furnace drops to 800°C, close the first gas valve and open the second gas valve, and let the argon flow into the chemical vapor deposition furnace until the temperature in the furnace drops to room temperature.

[0074] 4. Take out the product processed in the previous step, and clean it with acetone and alcohol; ball mill, the ball milling speed is 450r / min, and the ball milling time is 3h; dry, the drying time is 2h; granulate, add an appropriate amount of PVA during granulation; Tablets, the tableting pressure is 30Mpa, and the diameter of the tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com