Straw pocket-type in-situ composting method and device

A straw decomposing fungicide and composting technology, which is applied in fertilization devices, microorganism-based methods, biochemical equipment and methods, etc., can solve problems such as harming crops, breeding sources of pests, and increasing the cost of transportation resources, so as to facilitate air circulation. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the method and device of the present invention.

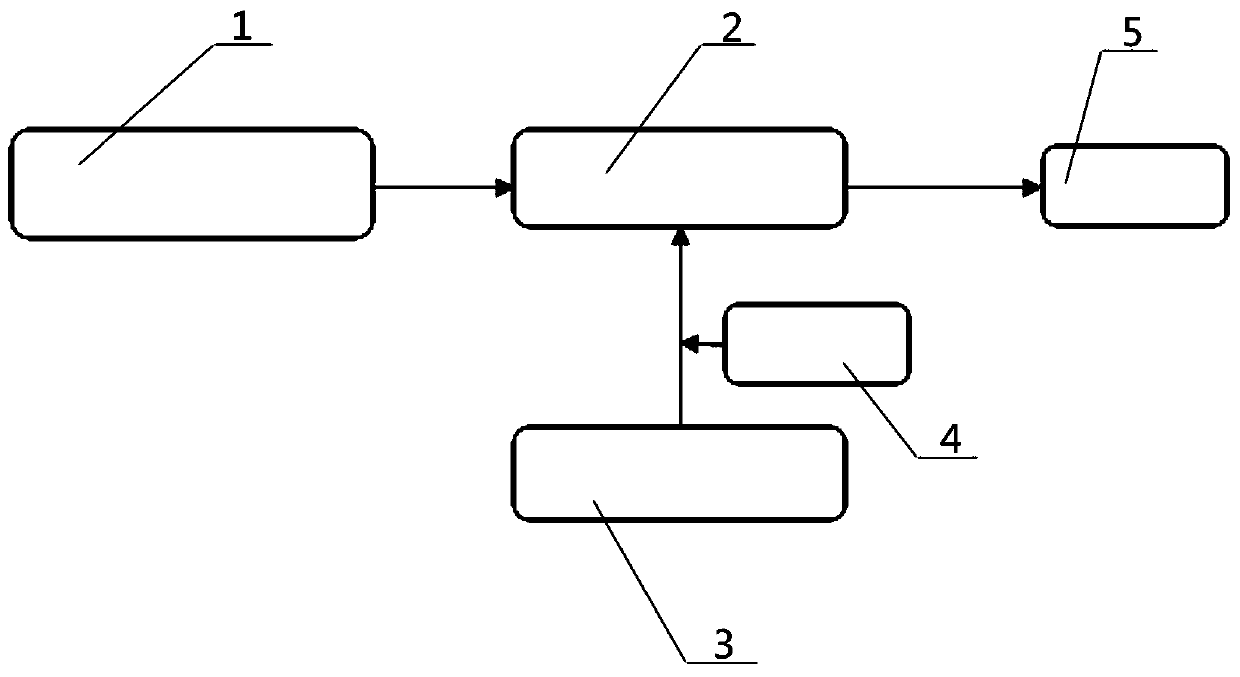

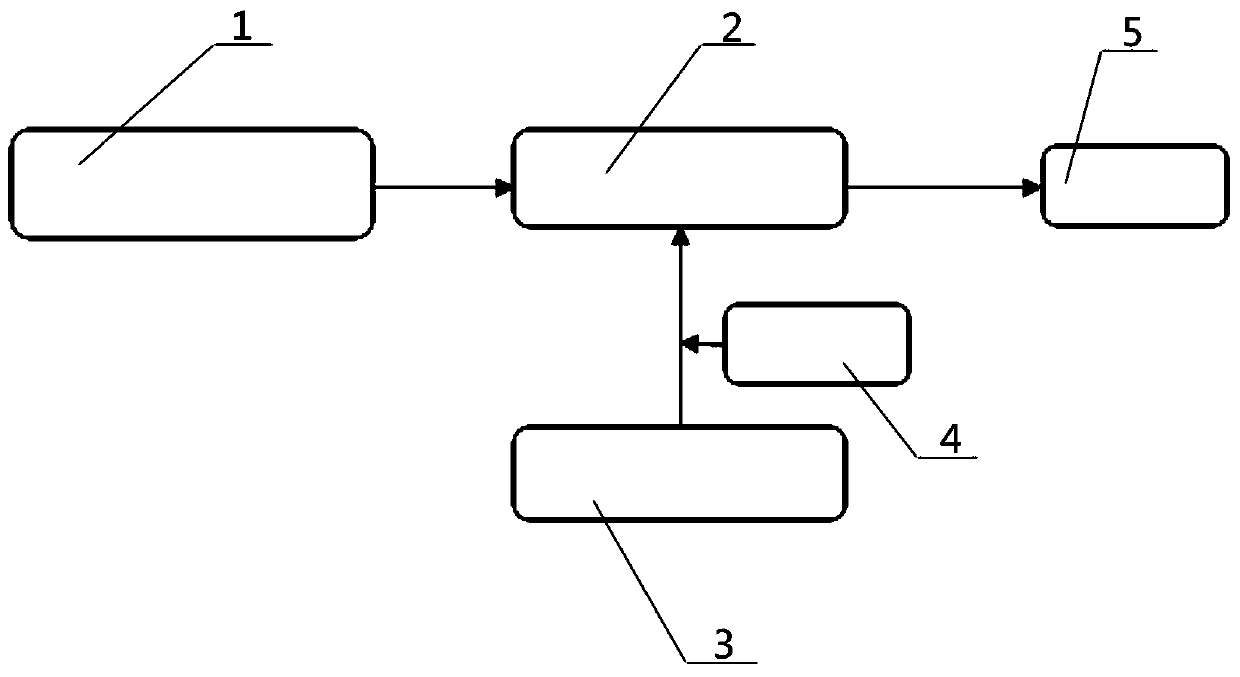

[0027]The straw bag-type in-situ composting and decomposing method of the present invention is as follows: select the crushed straw (using a pulverizer or the straw that has been crushed by a combine harvester in advance), send it to the mixer, and spray the straw decomposing bacteria agent in the mixer. The crushed straw is mixed, and directly sent into the compost bag by the mixer for in-situ composting and fermentation, and piled up to form a larger pile for heat preservation, so that the moisture content of the straw in the pile is maintained at 45%-60%. Under the biological fermentation of the decomposing bacteria agent, the straw powder quickly generates a high temperature of 60-70°C for fermentation and decomposing. When it is sown in spring, it is directly rotated in the farmland as a high-quality organic fertilizer. In the method of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com