Poly-3-aminophenylboronic acid carbon-based microbial fuel cell anode and preparation method thereof

An aminophenylboronic acid and aminophenylboronic acid membrane technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of low extracellular electron transfer speed, low anode bacterial load, and poor biological affinity, etc. Achieve the effect of fast extracellular electron transfer rate, high bacterial load and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Fe 3 o 4 Preparation method reference example 1 of nanosphere

[0057] Dissolve 5.4 g (0.02 mol) ferric chloride hexahydrate, 2 g (0.007 mol) sodium lauryl sulfate and 14.8 g (0.18 mol) sodium acetate in 100 mL ethylene glycol, stir and dissolve for 1 h at room temperature , heat the reaction at 200 °C for 10 h, cool to room temperature, centrifuge at 10000 r / min for 10 min in a desktop high-speed centrifuge, wash the precipitate with water for 3 times, and dry at 60 °C for 1 h to obtain 4 g Fe with an average particle size of 100 nm 3 o 4 nanospheres.

Embodiment 1

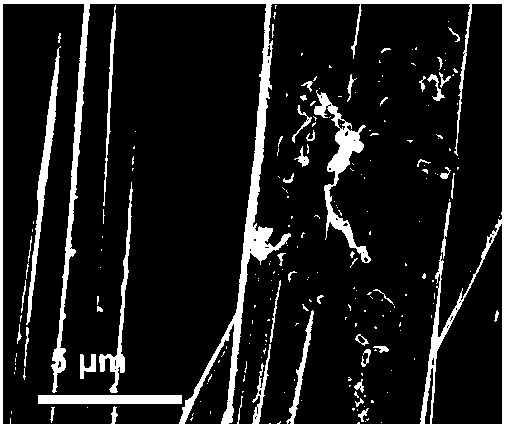

[0059] The carbon cloth microbial fuel cell anode of poly(m-aminophenylboronic acid) is made of porous poly(m-aminophenylboric acid) membrane at 0.1 mg / cm 2 Loaded on carbon cloth; the average pore diameter of the porous poly-m-aminophenylboronic acid membrane is 20 nm; the average thickness of the porous poly-m-aminophenylboronic acid membrane is 30 nm.

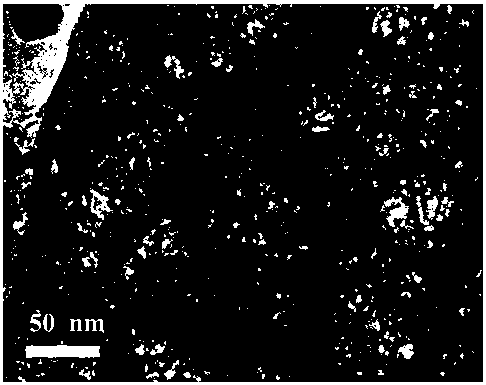

[0060] like figure 1 As shown, the carbon cloth microbial fuel cell anode of the poly(m-aminophenylboronic acid) in the embodiment of the present invention is supported on the carbon cloth by the porous poly(m-aminophenylboric acid) membrane, and the average pore diameter of the porous poly(m-aminophenylboronic acid) membrane is 20 nm.

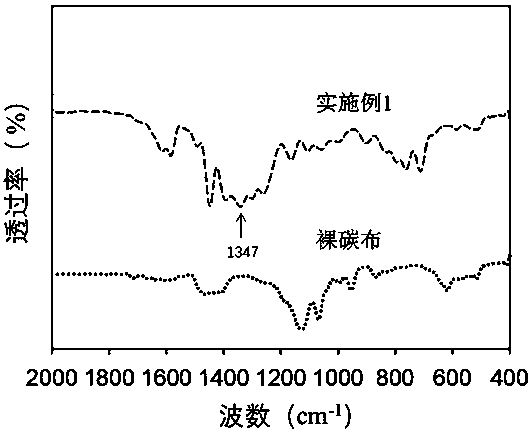

[0061] like figure 2 As shown, the carbon cloth microbial fuel cell anode of the embodiment of the present invention poly-m-aminophenylboronic acid is at 1347cm -1 There are obvious characteristic peaks of boronic acid groups, while the bare carbon cloth has no characteristic peaks here, ...

Embodiment 2

[0074] The carbon felt microbial fuel cell anode of described poly-m-aminophenylboronic acid is made of porous poly-m-aminophenylboronic acid film at 0.15mg / cm 2 Loaded on carbon felt; the average pore diameter of the porous poly-m-aminophenylboronic acid membrane is 100 nm; the average thickness of the porous poly-m-aminophenylboronic acid membrane is 25 nm.

[0075] After testing, the anode of the carbon felt microbial fuel cell of poly(m-aminophenylboronic acid) in the embodiment of the present invention is supported on the carbon felt by a porous poly(m-aminophenylboronic acid) membrane, and the average pore diameter of the porous poly(m-aminophenylboronic acid) membrane is 100 nm.

[0076] After testing, the carbon felt microbial fuel cell anode of the embodiment of the present invention poly-m-aminophenylboronic acid is at 1347 cm -1 There are obvious characteristic peaks of boronic acid groups, while the bare carbon felt has no characteristic peaks here, which proves th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com