Method and device for deep desulfurization and alkali control of sulfur incineration tail gas by sodium process

A deep desulfurization and tail gas technology, applied in the field of sulfuric acid gas, tail gas sodium method deep desulfurization and alkali control after sulfur incineration, desulfurization separation device, can solve the problem of difficult desulfurization efficiency of the system, incomplete removal of mist eliminators, increased investment costs, etc. problems, to achieve the effect of avoiding white smoke, reducing mist content, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

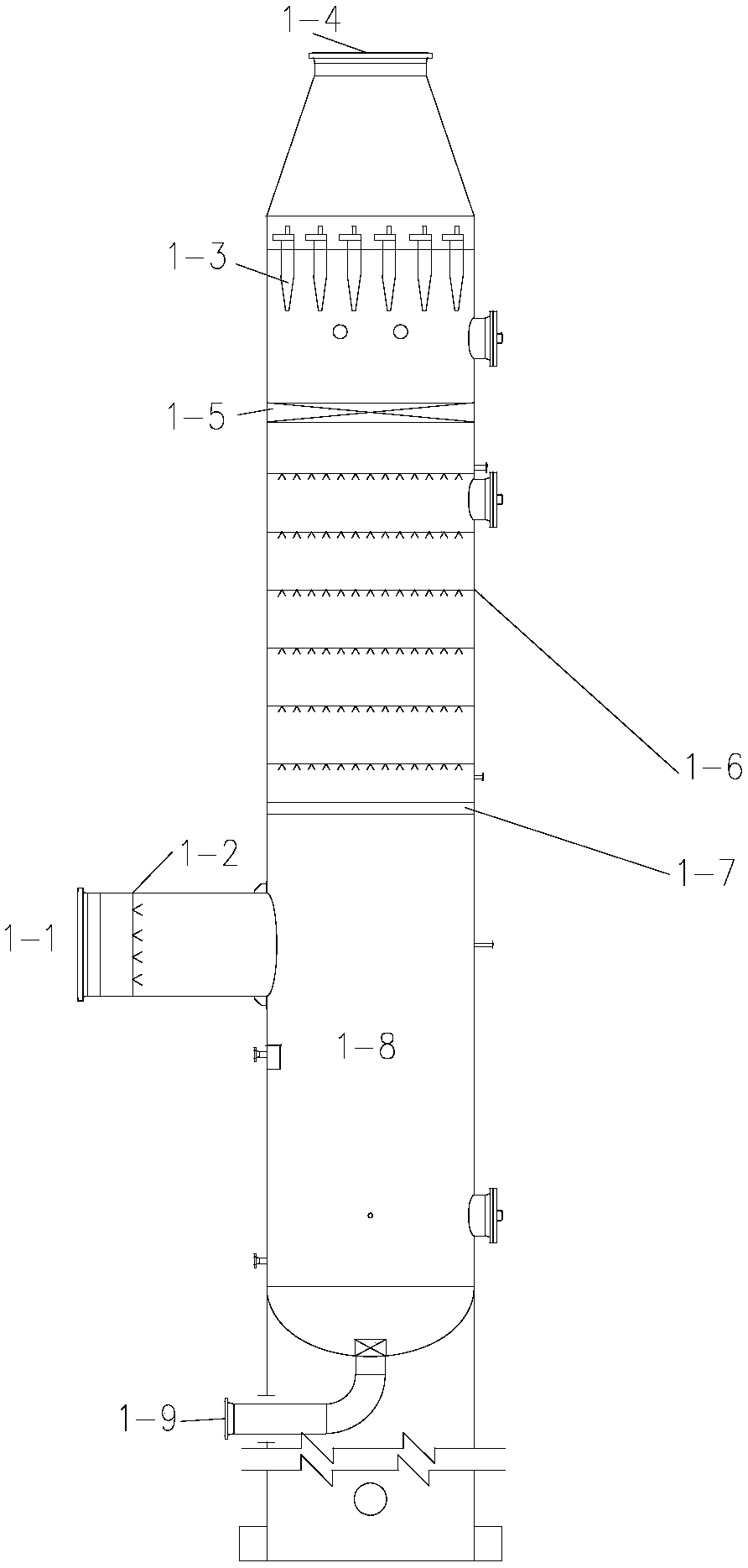

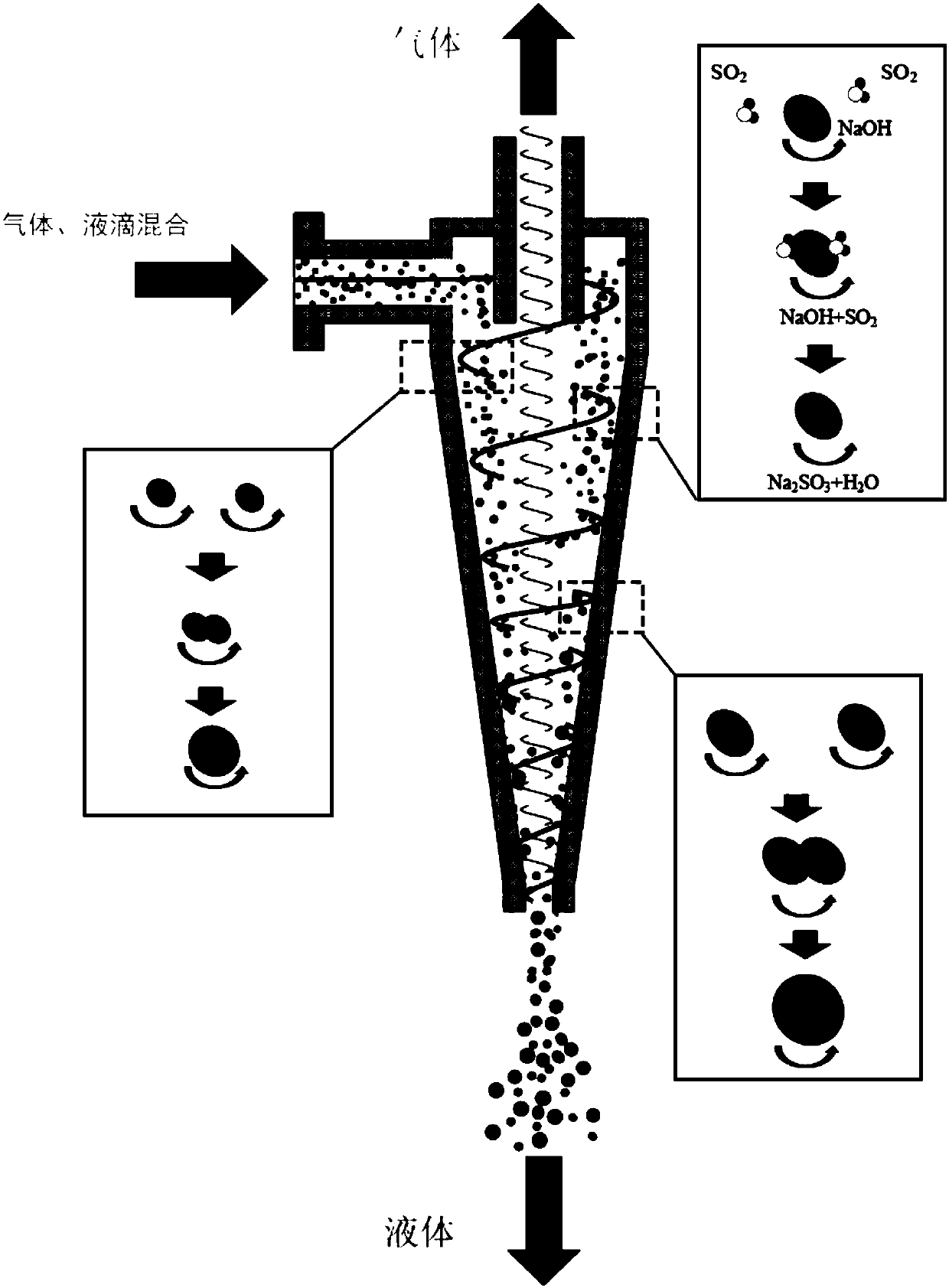

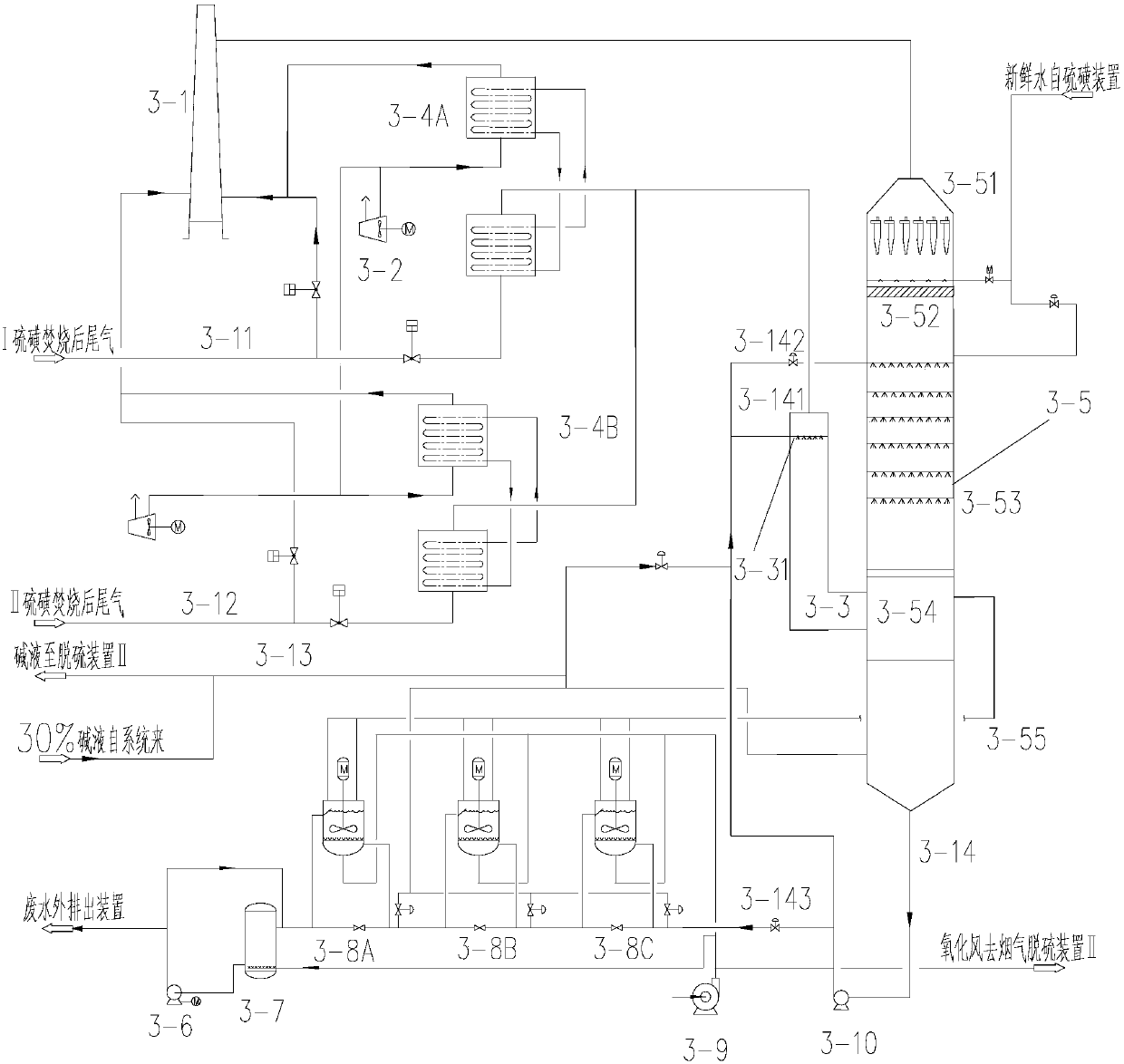

[0107]In the flue gas desulfurization device in the sulfur recovery unit of a 40 million tons / year refining and chemical integration project phase I project of Zhejiang Petrochemical Co., Ltd., according to the method of the present invention, the sodium method wet desulfurization and alkali control method is adopted, Filter and purify the flue gas containing solid particles and sulfur dioxide, and remove the particles and sulfur components. The specific operation process and effect are described as follows:

[0108] 1. Material properties and related parameters

[0109] The temperature of the tail gas after incineration in the sulfur plant is 260°C, and the density is 0.6523kg / m 3 , the flue gas volume is 16091-122700Nm 3 / h, the sulfur dioxide content is 560mg / Nm 3 (approximately 200ppm), the feed water is fresh water from the sulfur plant, the temperature is 40°C, and the pressure is 0.4MPa. The lye is sodium hydroxide solution, the concentration of lye is 30%wt, the nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com