Method for preparing metal single-atom catalyst

A catalyst and atomic technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as unknown heterogeneous phases, difficult artificial control, complicated MOFs crystal growth process, etc., to achieve high porosity rate, high specific surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of Fe single-atom catalyst is as follows:

[0030] (1) Preparation of Zr-based metal-organic framework materials containing bipyridyl groups

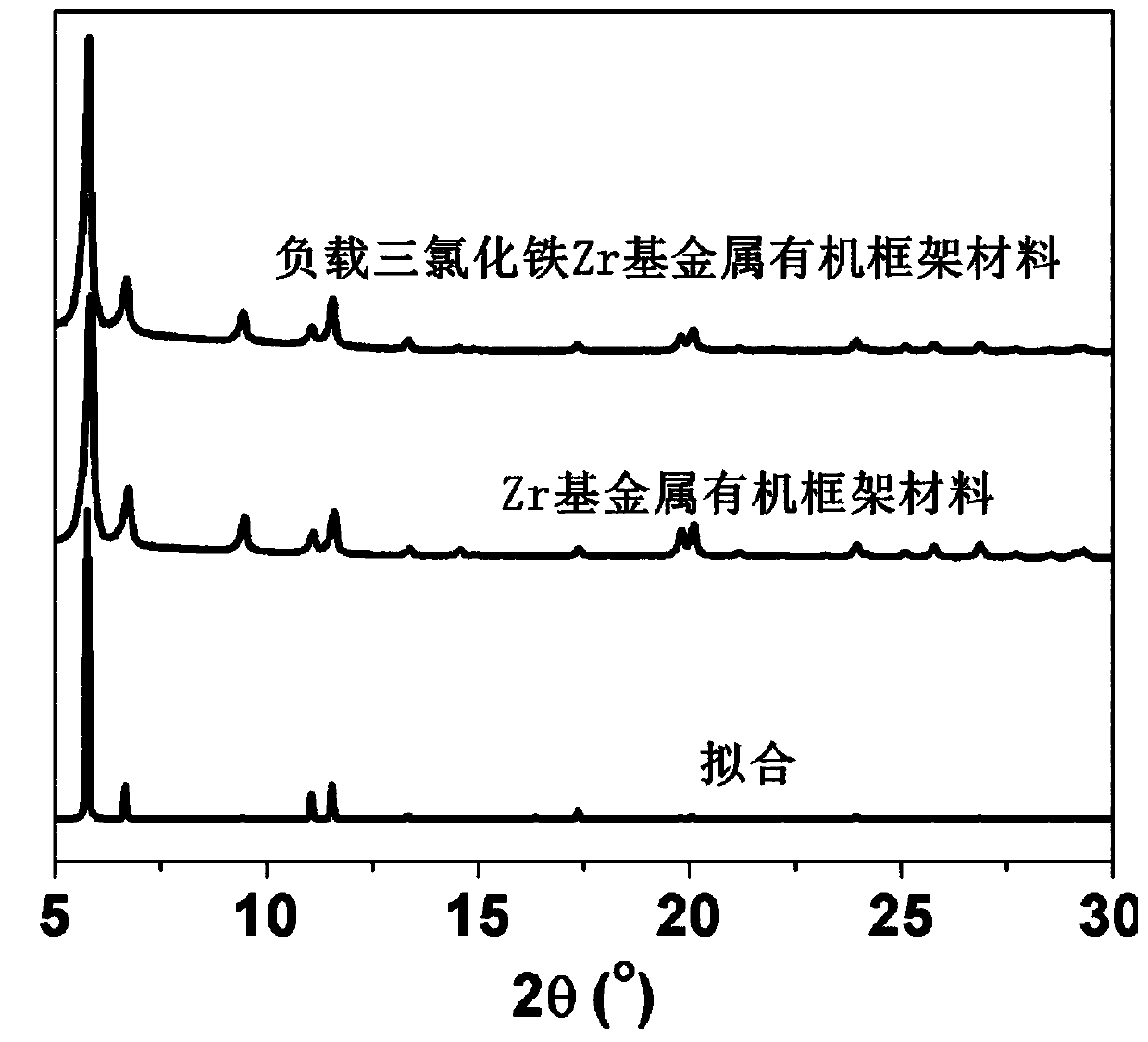

[0031] 0.246g ZrCl 4 , 0.260g of 2,2′-bipyridyl-5,5′-dicarboxylic acid and 7mL of formic acid were added to 100mL of N,N′-dimethylformamide solvent, fully dissolved and then transferred to a liner containing polytetrafluoroethylene In a stainless steel reactor, react at 120°C for 24h. The reacted product was centrifuged and washed with acetone for 2-3 times, dried at 80°C for 2h, and then transferred to a vacuum drying oven at 160°C for 12h in vacuum. The white product obtained was Zr-based metal organic framework material, whose structure is a metal-organic framework material with UiO type, such as figure 1 As shown, its PXRD is consistent with the fitted PXRD.

[0032] (2) Preparation of Zr-based metal-organic framework materials loaded with ferric chloride

Embodiment 2

[0043] In this example, the preparation method of the Co single-atom catalyst is basically the same as that in Example 1, except that the iron chloride hexahydrate in step (2) is replaced by cobalt chloride hexahydrate.

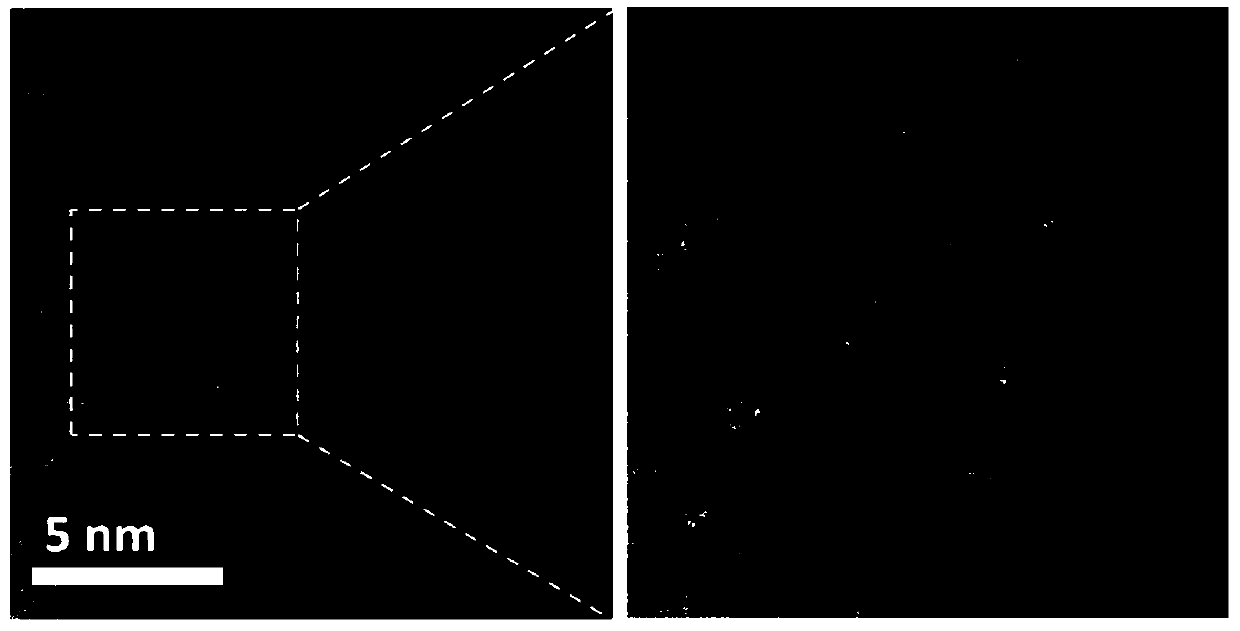

[0044] The spherical aberration electron microscope picture of the Co single-atom catalyst prepared above is as follows: Figure 5 As shown, it can be seen that Co single atoms are uniformly dispersed on the C substrate.

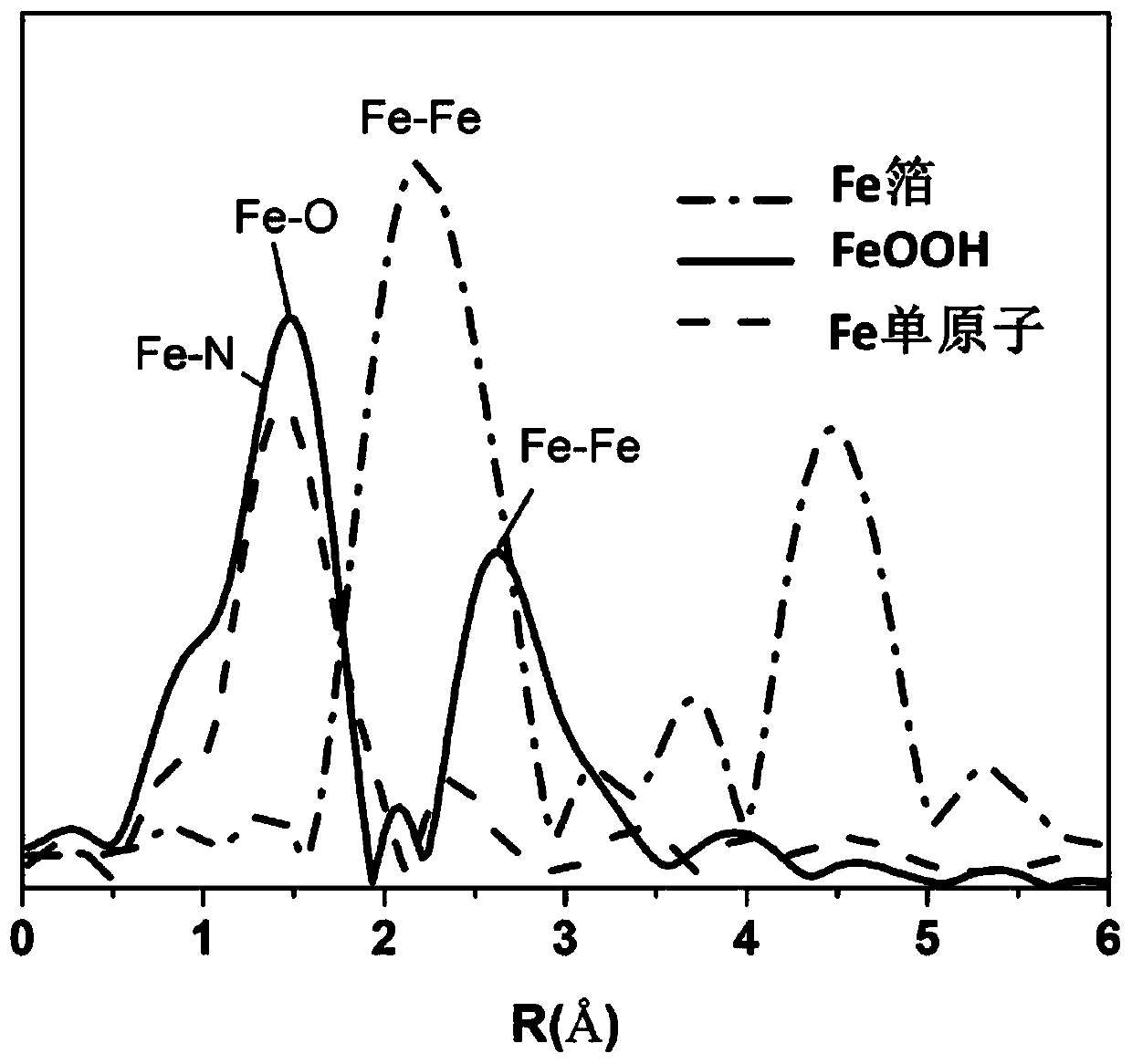

[0045] The synchrotron radiation EXAFS results of the Co single-atom catalyst prepared above are similar to Example 1, showing that there is no Co-Co bond in the Co single-atom catalyst, that is, there are no Co nanoparticles.

Embodiment 3

[0047] In the present embodiment, the preparation method of Ni single-atom catalyst is basically the same as the preparation method in Example 1 as follows, the difference is: replace the ferric chloride hexahydrate in step (2) with nickel chloride hexahydrate, solvent modification to acetonitrile.

[0048] The spherical aberration electron microscope picture of the Ni single-atom catalyst made above is as follows Figure 6 As shown, it can be seen that Ni single atoms are uniformly dispersed on the C substrate.

[0049] The synchrotron radiation EXAFS results of the Ni single-atom catalyst prepared above are similar to Example 1, showing that there is no Ni-Ni bond in the Co single-atom catalyst, that is, there are no Ni nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com