A preparation method of advanced metal matrix composite material for brake disc

A composite material and metal-based technology, applied in the field of preparation of advanced metal-based composite materials for brake discs, can solve the problems of cumbersome process steps, heat preservation and low production efficiency, and achieve simple process, low production efficiency and mechanical performance indicators excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

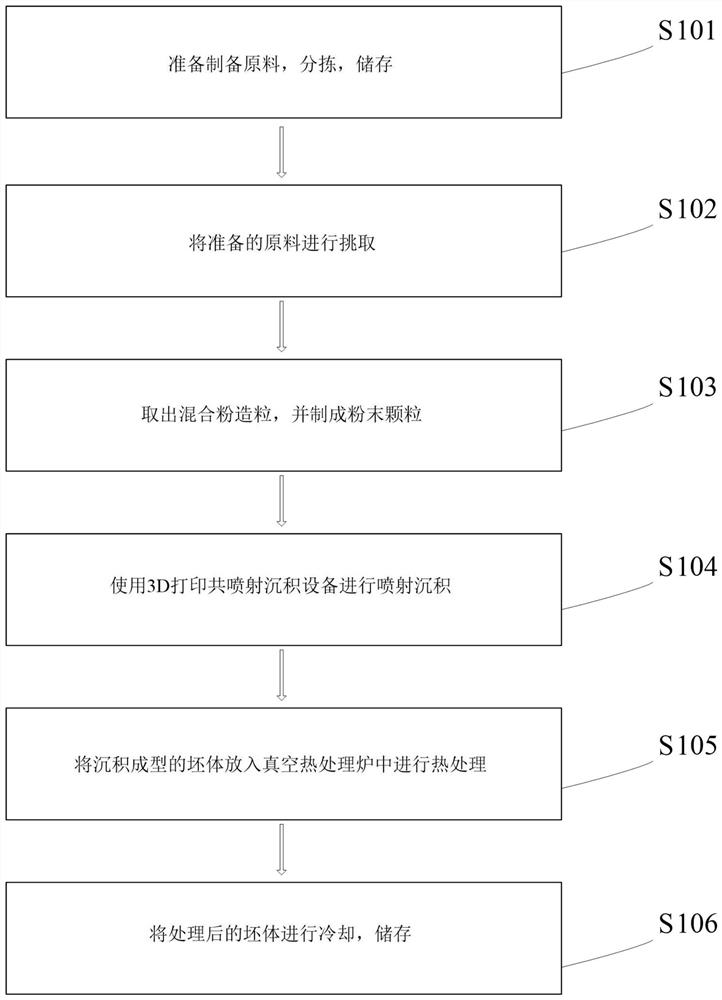

[0040] A method for preparing an advanced metal matrix composite material for a brake disc specifically includes the following steps:

[0041] S101: preparing raw materials, TiC powder, graphite powder, Ti powder, Al powder and Si powder are used as raw materials, sorted and stored;

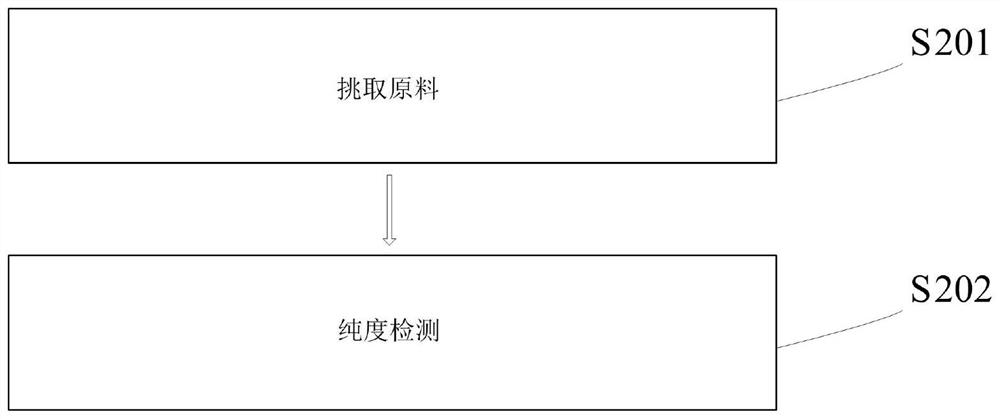

[0042] S102: Pick the prepared raw materials, the specific operation steps are as follows:

[0043] S201: pick raw materials, select TiC powder, graphite powder, Ti powder, Al powder and Si powder, and observe and select through a magnifying glass;

[0044] S202: Purity detection, by performing purity detection on TiC powder, graphite powder, Ti powder, Al powder and Si powder;

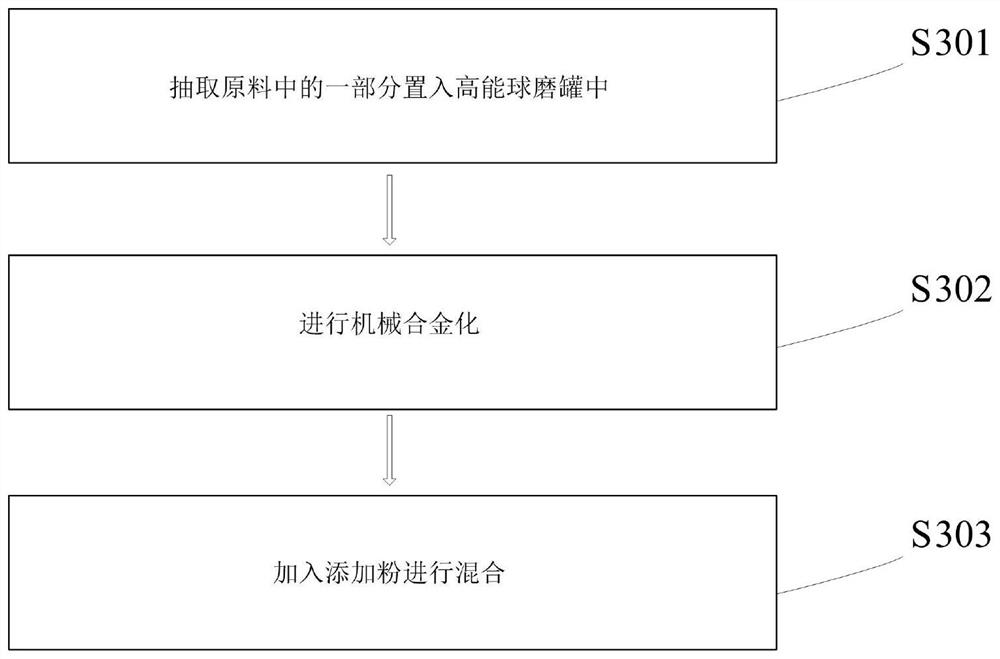

[0045] S103: Take out the mixed powder and granulate, and make powder granules, the specific operation steps are as follows:

[0046] S301: Extract a part of the raw materials and put them into the high-energy ball mill tank according to the ratio within a reasonable range;

[0047] S302: filling argon into the high-e...

specific Embodiment 1

[0066] 1. Use TiC powder, graphite powder, Ti powder, Al powder, and Si powder with a purity of not less than 99.9% as raw materials, and the particle size of TiC powder, graphite powder, Ti powder, Al powder, and Si powder is required to be ≤10 μm.

[0067] 2. Put Ti powder, Si powder and graphite powder into a high-energy ball mill tank according to Ti-0.2Si-1.2C, fill it with argon gas and carry out mechanical alloying for 48 hours, then add 0.2TiC-0.1Al powder and mix for 5-10 hours.

[0068] 3. Take out the mixed powder and granulate to make spherical particles with a diameter of 0.1mm, and put the prepared powder particles into powder feeder A; granulate the Al powder to make spherical particles with a diameter of 0.1mm, and put the prepared powder Powder particles are loaded into powder feeder B.

[0069] 4. Use 3D printing co-spray deposition equipment, spray deposition under nitrogen protection environment, control nozzle aperture 0.5mm, nozzle moving speed 1mm / s, air...

specific Embodiment 2

[0073] 1. Use TiC powder, graphite powder, Ti powder, Al powder, and Si powder with a purity of not less than 99.9% as raw materials, and the particle size of TiC powder, graphite powder, Ti powder, Al powder, and Si powder is required to be ≤10 μm.

[0074] 2. Put Ti powder, Si powder and graphite powder into a high-energy ball mill tank according to Ti-0.3Si-1.5C, fill it with argon gas and carry out mechanical alloying for 48 hours, then add 0.1TiC-0.1Al powder and mix for 5-10 hours.

[0075] 3. Take out the mixed powder and granulate to make spherical particles with a diameter of 0.1mm, and put the prepared powder particles into powder feeder A; granulate the Al powder to make spherical particles with a diameter of 0.1mm, and put the prepared powder Powder particles are loaded into powder feeder B.

[0076] 4. Use 3D printing co-spray deposition equipment, spray deposition in a nitrogen protection environment, control the nozzle aperture to 1.0mm, the nozzle moving speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com