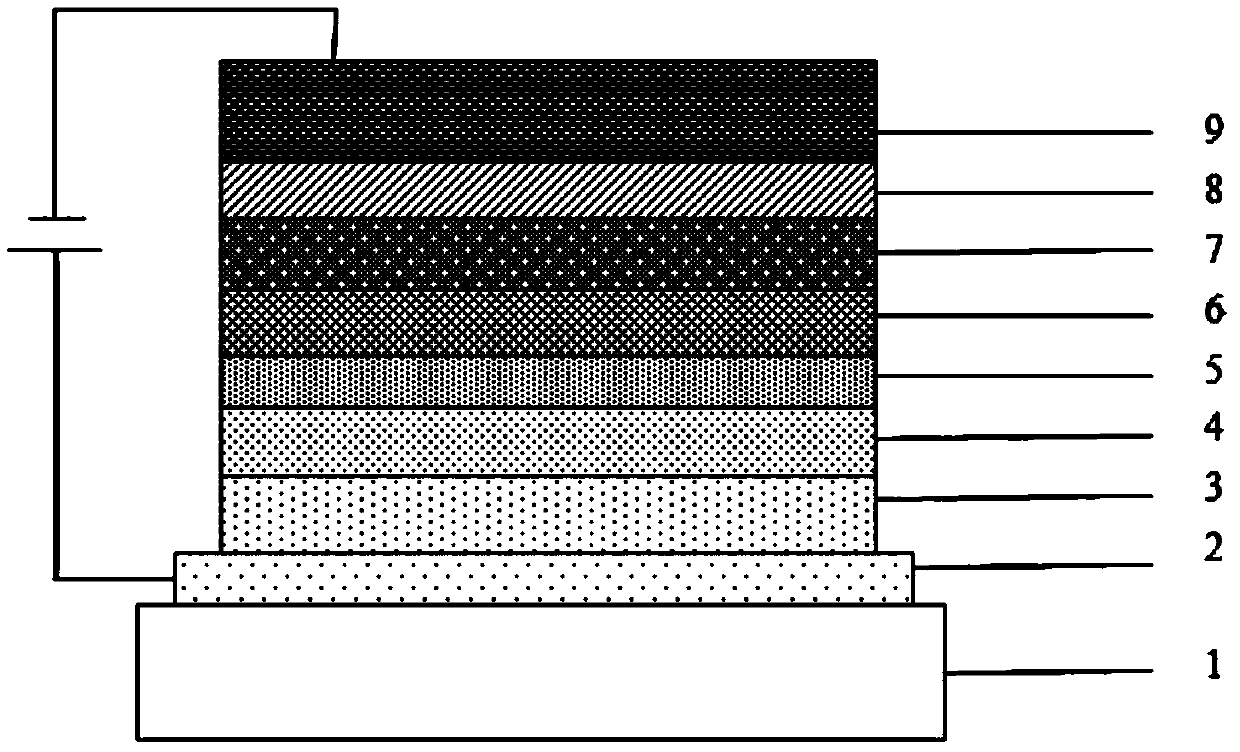

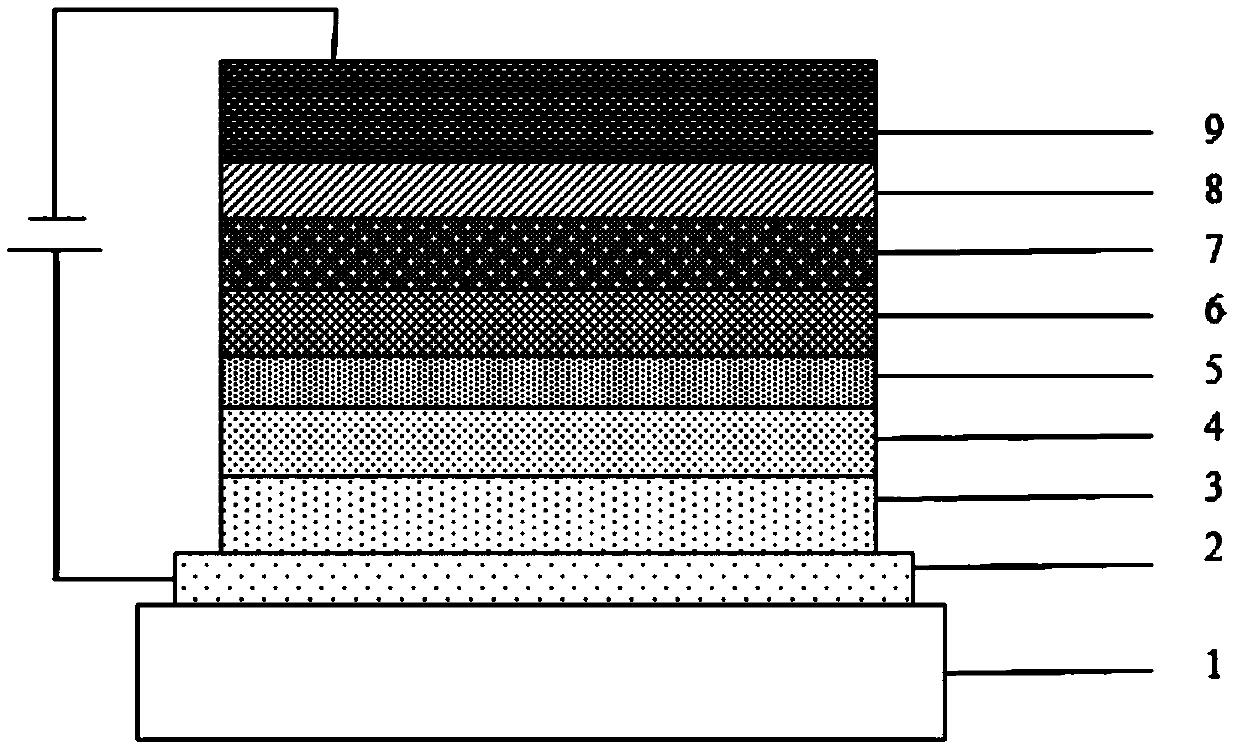

Organic metal iridium complex, preparation method and application thereof in OLED

An iridium complex and organometallic technology, applied in the field of organometallic iridium complexes, can solve problems such as poor carrier transport capability, impact on product quality and commercial competitiveness, high cost, etc., and achieve improved device life and good industrialization Prospect, the effect of lowering the driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

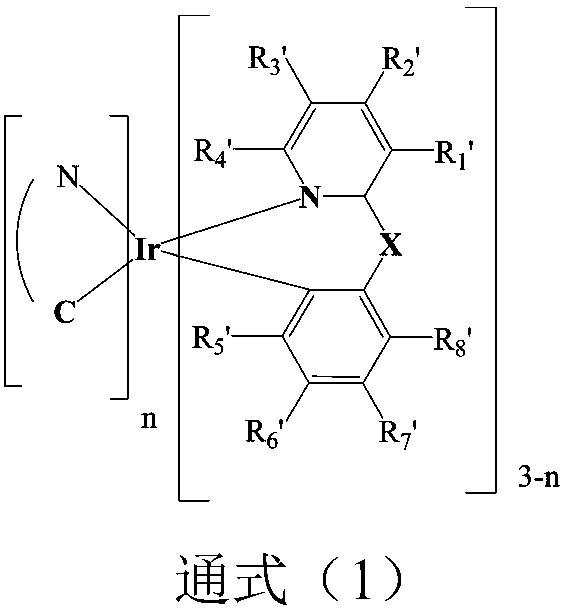

Method used

Image

Examples

Embodiment 1

[0051] The preparation of embodiment 1 organometallic iridium complex

Embodiment 1-1

[0052] The preparation of embodiment 1-1 complex 1

[0053] Step (1): Preparation of intermediate D1

[0054]

[0055] In a 150mL three-necked flask, feed nitrogen gas, add 3.53g (10mmol) iridium trichloride trihydrate, 3.41g (22mmol) 2-phenylpyridine, 60mL ethylene glycol methyl ether and 20mL distilled water, stir, and heat up to 120°C , reflux reaction for 17h, the solution was yellow and turbid, then stopped heating, filtered after natural cooling, the filter cake was washed with 50mL ethanol, 50mL water, 50mL ethanol in turn, drained and dried to obtain yellow powder intermediate D1;

[0056] Step (2): Preparation of Intermediate S1

[0057]

[0058] Add 2.14g (2mmol) of intermediate D1 and 100mL of dichloromethane into a 250mL three-necked flask, stir and dissolve at room temperature, and slowly add 50mL of silver trifluoromethanesulfonate methanol solution (0.084M) dropwise at room temperature in the dark. 0.5h, stirred at room temperature for 18h, the solution ...

Embodiment 1-2

[0063] The preparation of embodiment 1-2 complex 5

[0064] Step (1): Preparation of Intermediate D2

[0065]

[0066] In a 150mL three-necked flask, nitrogen gas was introduced, and 3.53g (10mmol) iridium trichloride trihydrate, 4.03g (22mmol) 3,5-dimethyl-2-phenylpyridine, 60mL ethylene glycol methyl ether and 20mL Distilled water, stirred, heated up to 120°C, refluxed for 17 hours, the solution turned yellow and turbid, then stopped heating, cooled naturally and filtered, the filter cake was washed with 50mL ethanol, 50mL water, 50mL ethanol in turn, drained and dried to obtain yellow Powder intermediate D2;

[0067] Step (2): Preparation of Intermediate S2

[0068]

[0069] Add 2.38g (2mmol) of intermediate D2 and 100mL of dichloromethane into a 250mL three-necked flask, stir and dissolve at room temperature, slowly drop into 50mL of silver trifluoromethanesulfonate methanol solution (0.084M) at room temperature in the dark, and add the time 0.5h, stirred at room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com