A marine micromonospora strain fermenting high-yielding rakicidin G and its application

A strain and marine technology, applied in the field of marine micromonospora strains fermented to produce RakicidinB1, can solve problems such as low fermentation yield, and achieve the effects of increasing fermentation yield, meeting industrialization needs, and reducing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

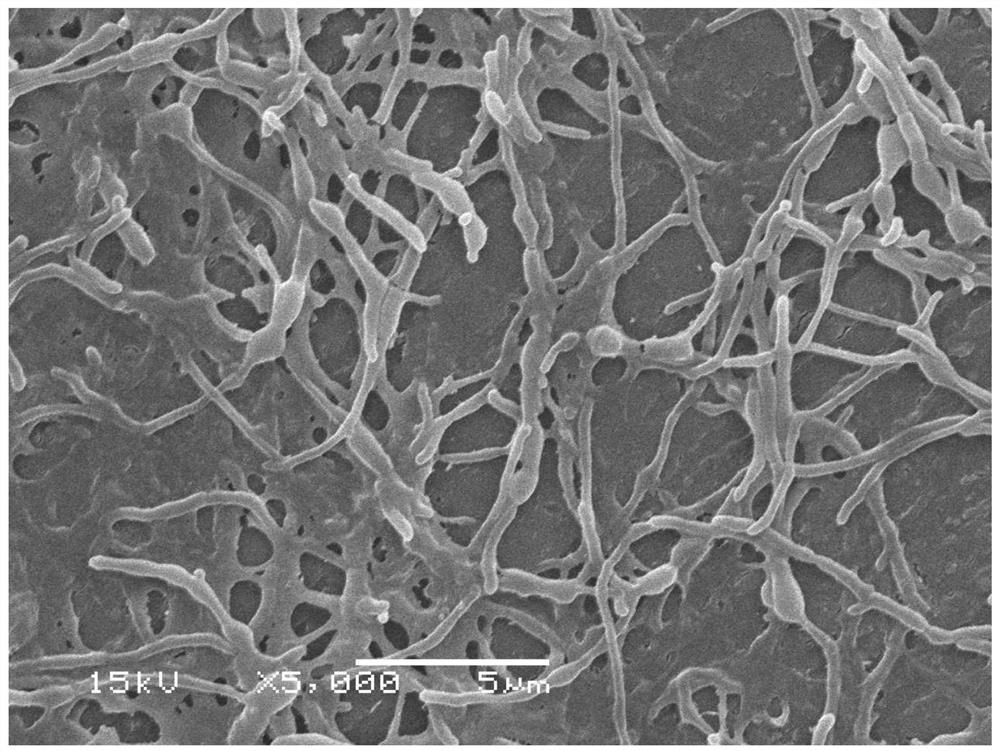

[0037] The mutation breeding of embodiment 1 bacterial strain

[0038] This embodiment illustrates that the mutagenesis breeding method of marine Micromonospora FIM-R181009 comprises the following steps:

[0039] (1) Preparation of spore suspension: add an appropriate amount of sterile saline to the fresh slant of the mature cultured starting strain FIM-R150103 (preservation number CGMCCNO.14822), gently scrape it with an inoculation spatula, and pour it into a sterile container with glass beads. Shake the flask to vibrate to disperse, then filter the mycelium, and leave the spore suspension for subsequent use;

[0040] (2) Nitrosoguanidine (NTG) mutagenesis: take 200mg NGT in a 100ml Erlenmeyer flask, add 2ml acetone, then add 18ml Tris-aminomethane maleic acid buffer, make it dissolve completely and mix uniformly to obtain a concentration of 20ml of 10mg / ml NTG solution; take the NTG mother solution and mix the prepared bacterial suspension so that the final NTG concentrati...

Embodiment 2

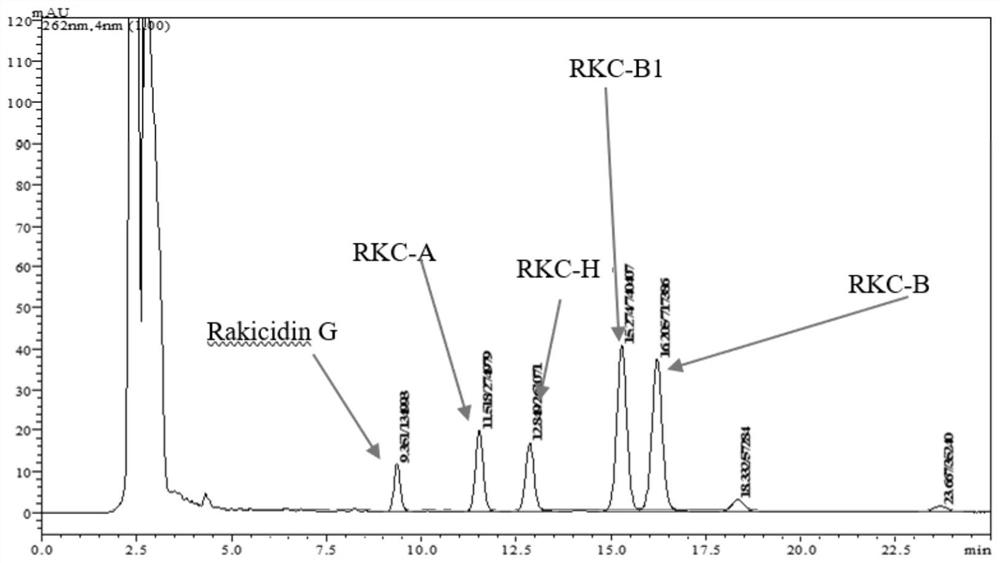

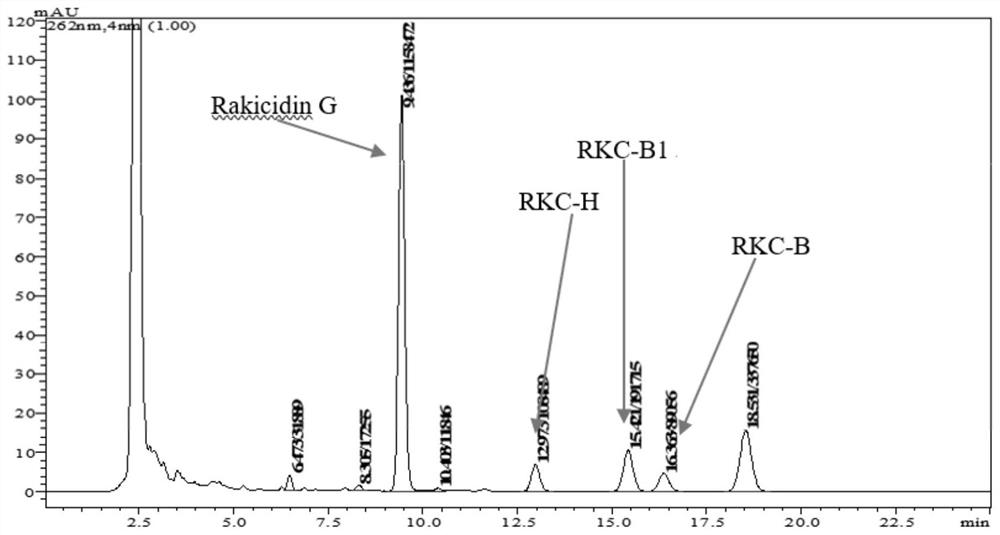

[0044] Embodiment 2 departure bacterial strain and mutant strain shake flask fermentation contrast

[0045] Scrape the slant spores of freshly cultured Micromonospora marina FIM150103 and the mutant strain FIM-R181009 and inoculate the suspension into the shake flask seed culture, cultivate at 32°C and 250rpm for 48 hours, and then inoculate at 8.0% Inoculate into the shake flask fermentation medium, culture at 30°C and 250rpm for 120 hours, release the bottle, and measure the fermentation product by HPLC (for HPLC detection, refer to Chinese patent CN108530379A).

[0046] Preparation of seed medium formula (mass fraction): 2.0% corn starch, 1.0% glucose, 1.1% corn protein, 2.2% Angel yeast extract powder, MgSO 4 ·7H 2 O 0.05%, KH 2 PO 4 0.05%, CaCO 3 0.3%, prepared with tap water, adjust the pH value to 7.2, and carry out seed liquid cultivation at 30°C after sterilization.

[0047] Preparation of fermentation medium formula (mass fraction): 5.0% corn starch, 1.0% gluc...

Embodiment 3

[0052] Embodiment 3 mutant strain FIM-R181009 is fermented on 20L fermenter

[0053] Prepare seed medium and fermentation medium according to the recipe in Example 2.

[0054] Seeds are shake flask seeds, 500ml shake flasks have a liquid volume of 100ml per bottle, cultivated at 32°C and 240rpm for 48 hours; then inoculate 8.0% inoculum in a 20L fermenter (actual liquid amount 13L) for fermentation, and cultivate at 30°C. Control the tank pressure to 0.03-0.05Mpa, start the rotation speed at 200rpm, gradually adjust to 360rpm after 48 hours according to the change of fermentation parameter DO, and the ventilation rate is 1:1vvm, and it will be about 96-120 hours until the end of fermentation.

[0055] During the fermentation process, the content of Rakicidins compounds in the fermentation broth of the mutant strain was detected by HPLC. The fermentation results are shown in Table 2 below. The final fermentation titer was: the Rakicidin G content was 317.29 mg / L.

[0056] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com