Grain fumigation process

A process and food technology, applied in food preservation, food science, edible seed preservation, etc., can solve the problems of poisonous, strong irritating gas, damage to the central nervous system, etc., and achieve the effect of low pollution, simple operation and wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of fumigant

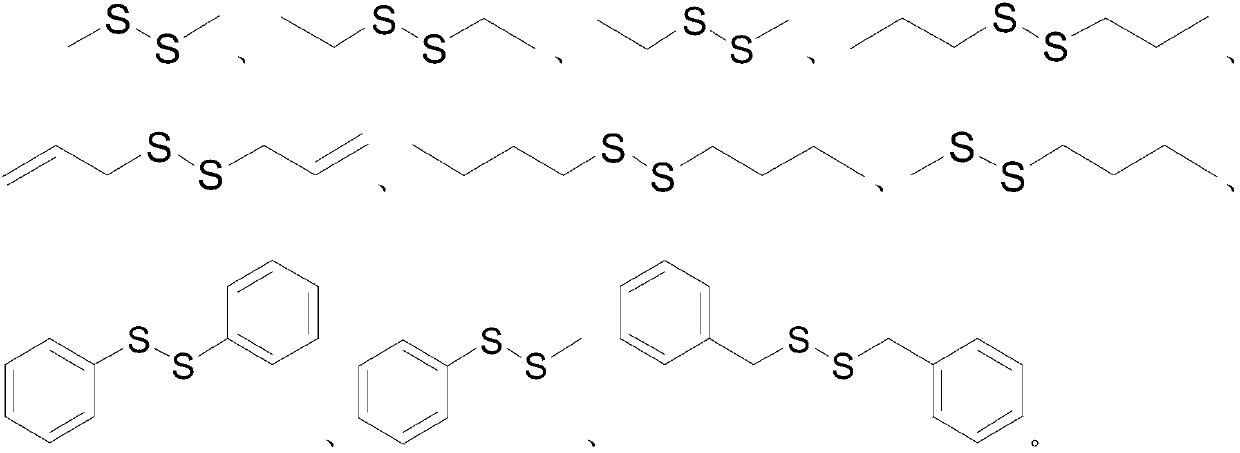

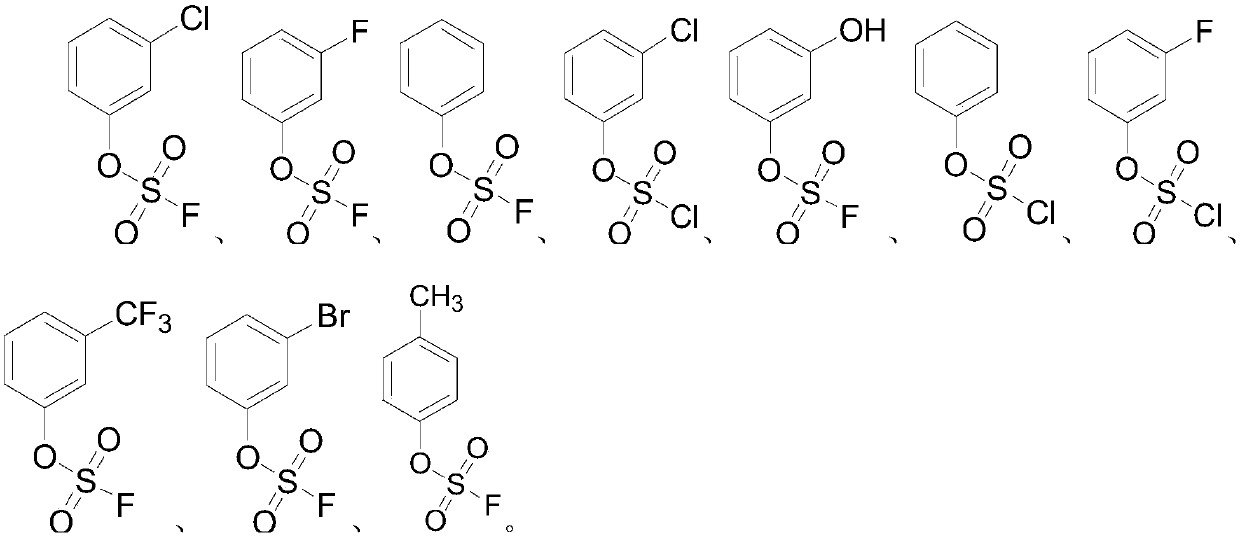

[0027] 1. Compounds of 1,2-dimethyl sulfide and phenyl fluorosulfonate:

[0028] Stir and mix 1,2-dimethyl sulfide and phenyl fluorosulfonate at room temperature according to the volume ratio of 2:3; it is abbreviated as fumigant A; the oral LD50 of mice is determined to be >500mg / Kg, which belongs to low poison.

[0029] 2. Compounds of 1,2-diethyl sulfide and vinyl sulfonyl fluoride:

[0030] Stir and mix 1,2-diethyl sulfide and vinyl sulfonyl fluoride evenly at room temperature according to the volume ratio of 2:1; abbreviated as fumigant B; the oral LD50 of mice is determined to be >500mg / Kg, which belongs to low toxicity .

[0031] 3. Compounds of 1-methyl-2-ethyl sulfide and m-chlorophenyl fluorosulfonate:

[0032] Stir and mix 1-methyl-2-ethyl sulfide and m-chlorophenyl fluorosulfonate at room temperature according to the volume ratio of 2:1; abbreviated as fumigant C; determine the oral LD50 of mice>500mg / Kg, bel...

Embodiment 2

[0045] Embodiment 2: grain fumigation experiment

[0046] Grain varieties: corn, rice, wheat, soybeans, soybeans, broad beans, potatoes, sweet potatoes, etc.

[0047] Diseases: Aspergillus, Penicillium, Trichoderma, Cladoderma cereus, Rhizopus, Trichoderma, Staphylococcus aureus, Escherichia coli, Bacillus megaterium, Bacillus subtilis and Pseudomonas fluorescens, black beetle, grain robber, etc.

[0048] Fumigant: Fumigant A

[0049] Fumigation method:

[0050] Put the fumigant and grain samples in the fumigation bin, close the fumigation box, control the temperature inside the fumigation box to 20°C, and after 36 hours of fumigation, depressurize the air for 1 hour, ventilate and replace the gas for 12 hours, and end the fumigation;

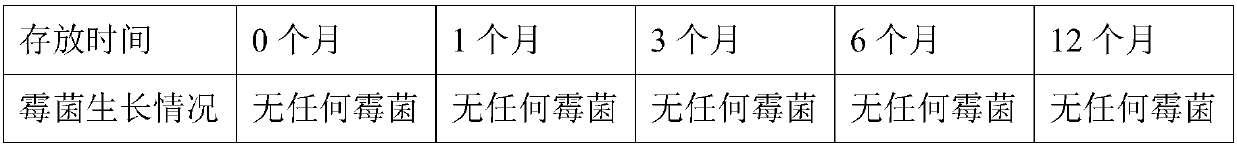

[0051] It is known by microscope inspection that no mold has grown on the grain samples after the above-mentioned fumigation treatment;

[0052] And it was detected and analyzed by gas chromatography and mass spectrometry (GC-Ms) that there ...

Embodiment 3

[0056] Embodiment 3: grain fumigation experiment

[0057] Grain varieties: corn, rice, wheat, soybeans, soybeans, broad beans, potatoes, sweet potatoes, etc.

[0058] Diseases: Aspergillus, Penicillium, Trichoderma, Cladoderma cereus, Rhizopus, Trichoderma, Staphylococcus aureus, Escherichia coli, Bacillus megaterium, Bacillus subtilis and Pseudomonas fluorescens, black beetle, grain beetle and Clothes fish etc.

[0059] Fumigant: Fumigant C

[0060] Put the fumigant and grain samples in the fumigation bin, close the fumigation box, control the temperature in the fumigation box to 25°C, and after 24 hours of fumigation, depressurize and pump for 48 hours, ventilate for 1 hour, and end the fumigation;

[0061] It is known by microscope inspection that no mold has grown on the grain samples after the above-mentioned fumigation treatment;

[0062]And by the detection and analysis of gas chromatography and mass spectrometry (GC-Ms), it is known that there is no fumigant residue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com