Three-phase catalyst Pd@COF-QA as well as preparation method and application thereof

A technology of catalysts and synthesis methods, applied in catalytic reactions, organic chemistry methods, chemical instruments and methods, etc., can solve the problem of unclear connection position and degree of connection between catalytic functional groups and carriers, uncertain polymer carrier structure, difficult Accurately analyze catalysts and other issues to achieve the effects of easy recovery, reduced energy consumption, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

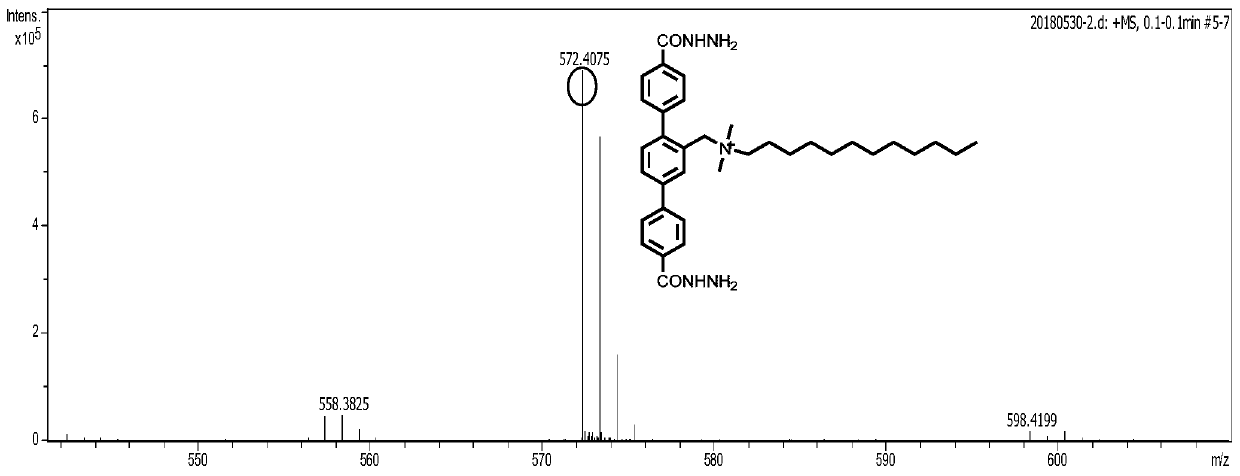

[0040] In yet another specific embodiment of the present invention, a synthesis method of the organic ligand L is provided, comprising the following steps:

[0041] (1) With 2,5-dibromotoluene and 4-methoxycarbonylphenylboronic acid as raw materials, cesium fluoride as base, tetrakis(triphenylphosphine palladium) as catalyst, in 1,4-dioxane solution, heated to 85-95° C. (preferably 90° C.) for reaction, silica gel column chromatography to separate the product, and decompression to remove the solvent to obtain intermediate product A. The structure of intermediate A is as follows:

[0042]

[0043] (2) intermediate A is reacted with N-bromosuccinimide (NBS) and azobisisobutyronitrile (AIBN), carbon tetrachloride is used as a solvent, and the product is separated by silica gel column chromatography to obtain intermediate B; The structural formula of the intermediate B is as follows:

[0044]

[0045] (3) Intermediate B is reacted with N,N-dimethyldodecylamine, acetonitrile...

Embodiment 1

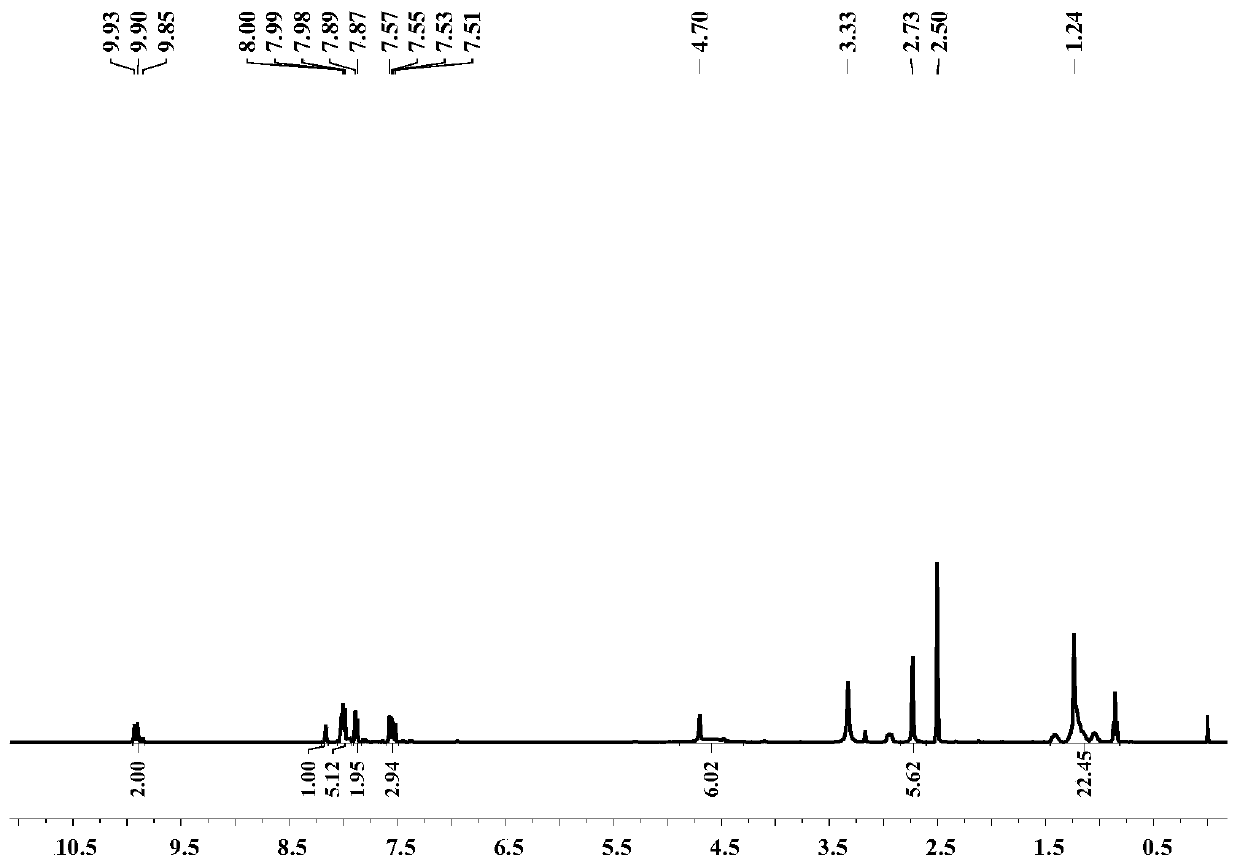

[0070] Embodiment 1: the preparation of organic ligand L

[0071] Concrete preparation steps are as follows:

[0072] (1) Under nitrogen protection, 4.33g (24mmol) 4-methoxycarbonylphenylboronic acid, 6g (40mmol) cesium fluoride were placed in a 250ml three-necked flask, and 150ml 1,4-dioxane and 2.754ml (10mmol) were added ) mixed solution of 2,5-dibromotoluene, and then add 1.6g of tetrakis(triphenylphosphine)palladium catalyst, and reflux at 90°C for 48h. After the reaction, an orange solution with black precipitate was obtained. The system was evaporated to dryness under reduced pressure, and after drying in the air, silica gel column chromatography (petroleum ether and dichloromethane) gave 3.0 g of a white product with a yield of 82%.

[0073]

[0074] (2) Under the protection of nitrogen, 2.5g (6.937mmol) of intermediate A, 0.114g (0.693mmol) of azobisisobutyronitrile, and 1.48g (8.324mmol) of N-bromosuccinimide were placed in a 100ml three-necked flask , Add 45ml...

Embodiment 2

[0081] Example 2: Synthesis of Pd@COF-QA

[0082]

[0083] (1) 29.40mg (0.045mmoL) of ligand L and 4.86mg (0.03mmoL) of trimesin tricarbaldehyde are placed in a pressure-resistant tube, add mesitylene: dioxane: acetic acid (6M) = 16:4 : 3 (volume ratio) mixed solvent 2mL in total, degassed under liquid nitrogen bath, then warmed up to room temperature, kept at 120 ℃ for 3 days (72h). Cool to room temperature, centrifuge, take out the precipitate, and vacuum-dry to obtain 0.039g. Yield: 47.3%.

[0084] (2) In a 25ml round-bottomed flask, first add palladium acetate (6mg), dissolve it in 5mL of dichloromethane, then add 20mg of COF-QA and stir at room temperature for 24 hours, after the reaction is completed, centrifuge, wash 3 times with dichloromethane, and then Washed with acetone three times, dried at 80°C for 3 h to obtain Pd@COF-QA.

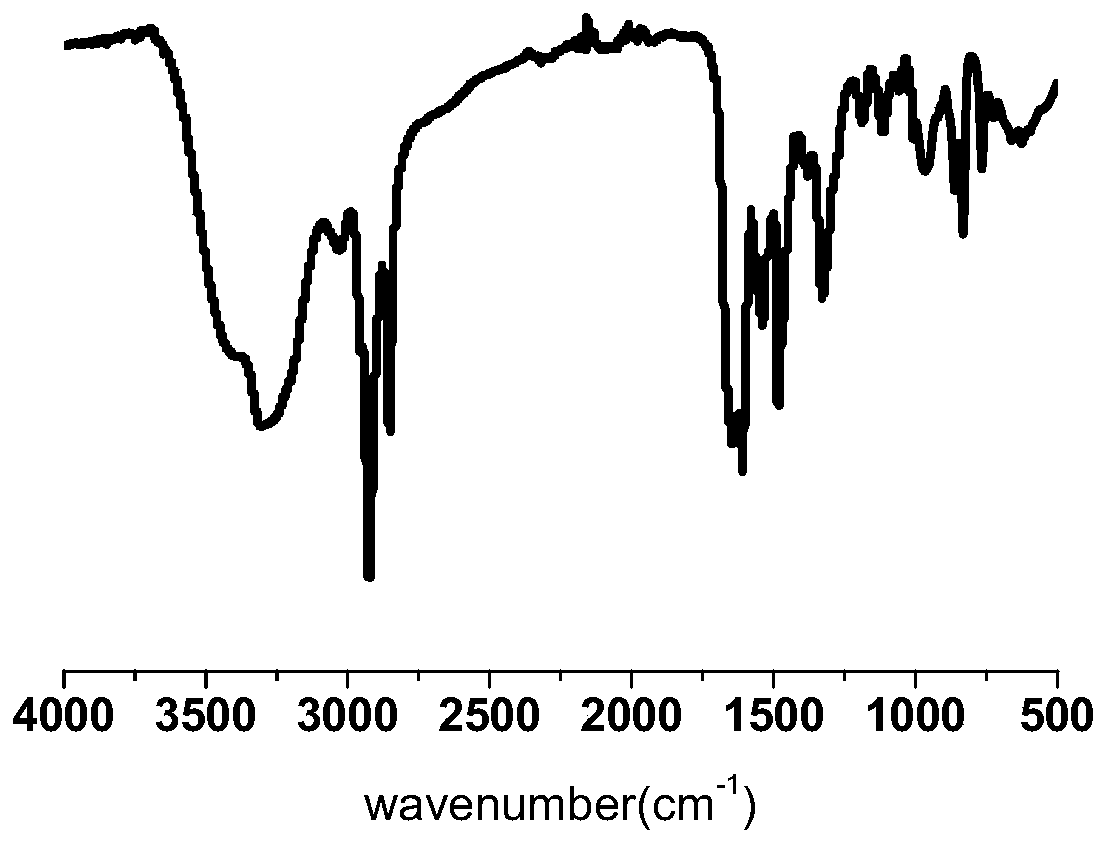

[0085] The polymer was characterized by IR and PXRD, the results are shown in Image 6 , 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com