Low-carbon sulfur-containing round steel for air-conditioning pipes and production technology of round steel

A production process and round steel technology, applied in the field of low-carbon sulfur-containing round steel for air-conditioning pipes and its production technology, can solve the problems of few technical solutions for low-carbon sulfur-containing round steel, and achieve significant economic and social benefits. High finish and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

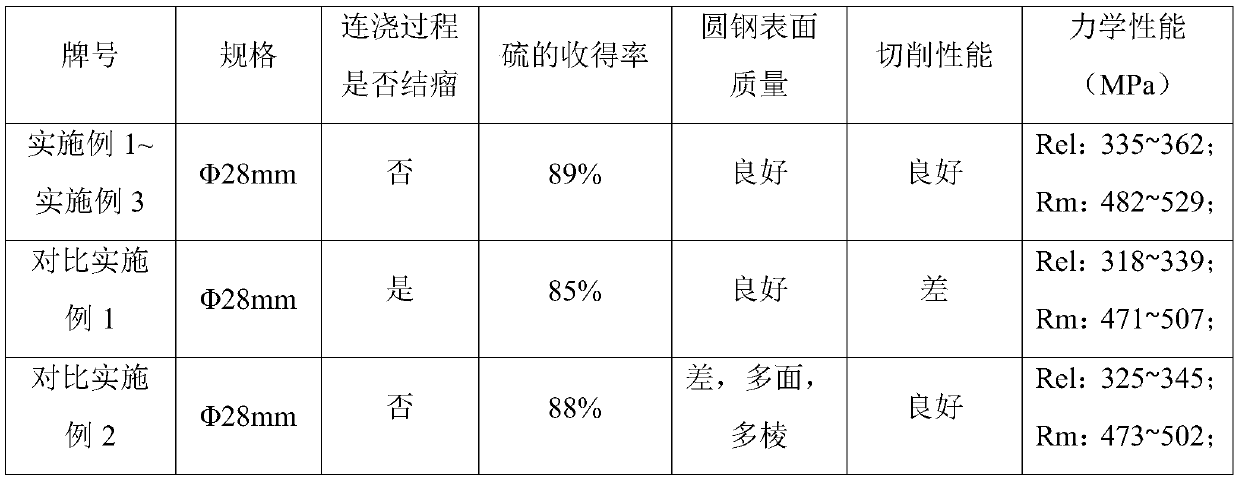

Examples

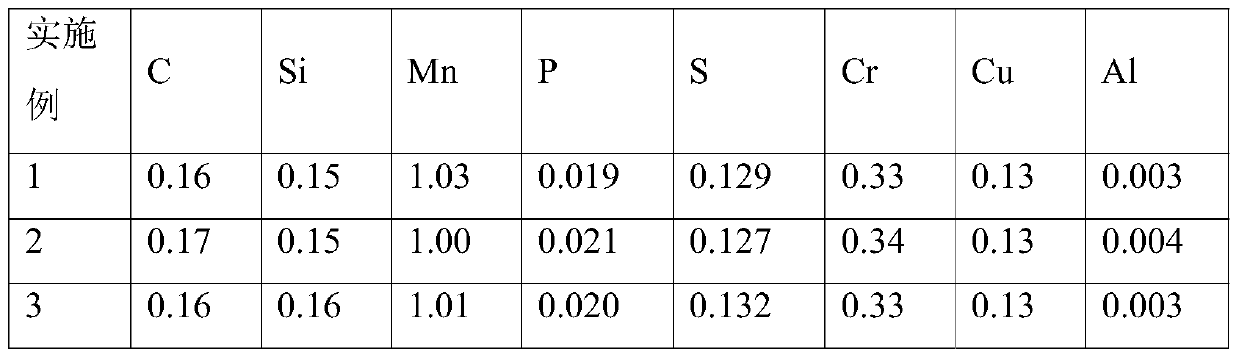

Embodiment 1

[0047] (1) The steel-making raw material that converter adopts is scrap steel and molten iron, and scrap steel accounts for 14% of described steel-making raw material gross weight, and molten iron accounts for 86% of described steel-making raw material gross weight, and total charging capacity is 142t / furnace;

[0048] (2) During the converter smelting process, the whole process of bottom blowing argon stirring is adopted, smelting for 15 minutes, tapping [C] 0.08%, tapping [P] 0.018%, tapping temperature 1635°C, tapping 1 / 4 of the time according to the order of steel flow Add aluminum block 0.5kg / t, silicon carbide 0.8kg / t, silicon manganese 6.9kg / t, ferrosilicon 0.6kg / t, low carbon ferromanganese 7.0kg / t, low carbon ferrochrome 5.8kg / t, copper 1.3 kg / t, iron sulfur 3.2kg / t; lime 400kg, slag blocking operation is adopted during the tapping process, slag dropping is strictly prohibited, and the tapping time is 4.1min;

[0049] (3) LF uses silicon carbide 0.5kg / t calcium carbid...

Embodiment 2

[0053] Compared with embodiment 1, wherein

[0054] Tapping [C] of step (2): 0.09%, tapping [P] 0.020%,

[0055] Step (3) The temperature of the ladle after soft blowing is 1580°C for continuous pouring.

[0056] Step (4) superheat degree 30 ℃,

[0057] All the other operations are the same as in Example 1.

Embodiment 3

[0059] Compared with embodiment 1, wherein

[0060] Step (5) The rolling start temperature is 1148° C., the KOCKS rolling mill temperature is 903° C., the upper cooling bed temperature is 707° C., and other operations are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com