A kind of non-deliquescent high-purity sulfur halide glass and its purification preparation method

A technology of sulfur-halide glass and high-purity sulfur, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of reducing the transmittance of sulfur-halide glass, increasing the light background scattering loss, etc., to achieve uniform optical quality, Good infrared transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The molar composition of the non-deliquescent high-purity sulfur halide glass of embodiment 1 is expressed as (Ge 10 As 22 Se 68 ) 90 I 10 , including the following steps:

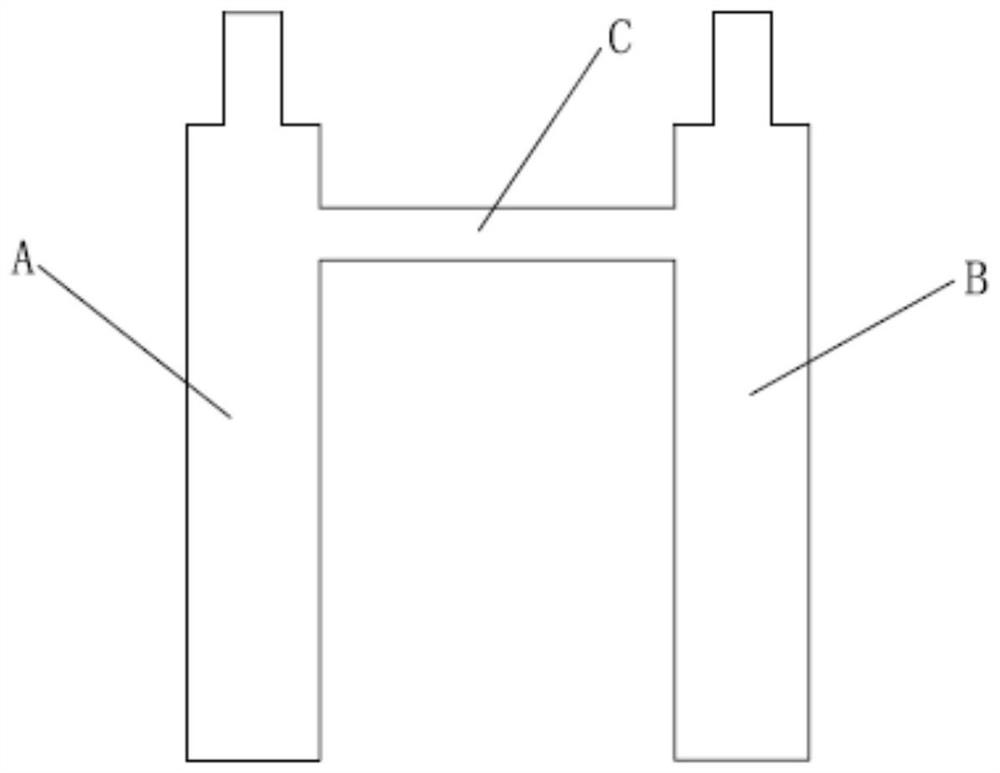

[0029] 1) Weigh elemental germanium, elemental arsenic, and elemental selenium with a purity of not less than 99.9% according to the chemical formula, and mix them evenly to obtain a mixture; weigh magnesium strips as an oxygen scavenger, and the amount of the oxygen scavenger to be weighed is For 0.035wt% of the total amount of the mixture; 2) prepare a H-type double-tube quartz ampoule through dehydroxylation pretreatment, such as figure 1 As shown, the H-type double-tube quartz ampoule includes a glass raw material tube A and a purified glass tube B, the glass raw material tube A and the purified glass tube B communicate through a connecting tube C, and the upper ends of the glass raw material tube A and the purified glass tube B are opened respectively; The mixture obtained in step 1) and t...

Embodiment 2

[0031] The molar composition of the non-deliquescent high-purity sulfur halide glass of embodiment 2 is expressed as (Ge 10 As 22 Se 68 ) 88 I 12 , including the following steps:

[0032] 1) Weigh elemental germanium, elemental arsenic, and elemental selenium with a purity of not less than 99.9% according to the chemical formula, and mix them evenly to obtain a mixture; weigh magnesium strips as an oxygen scavenger, and the amount of the oxygen scavenger to be weighed is For 0.035wt% of the total amount of the mixture; 2) prepare a H-type double-tube quartz ampoule through dehydroxylation pretreatment, such as figure 1 As shown, the H-type double-tube quartz ampoule includes a glass raw material tube A and a purified glass tube B, the glass raw material tube A and the purified glass tube B communicate through a connecting tube C, and the upper ends of the glass raw material tube A and the purified glass tube B are opened respectively; The mixture obtained in step 1) and t...

Embodiment 3

[0034] The molar composition of the non-deliquescent high-purity sulfur halide glass of embodiment 3 is expressed as (Ge 33 As 12 Se 55 ) 85 I 15 , including the following steps:

[0035] 1) Weigh elemental germanium, elemental arsenic, and elemental selenium with a purity of not less than 99.9% according to the chemical formula, and mix them evenly to obtain a mixture; weigh magnesium strips as an oxygen scavenger, and the amount of the oxygen scavenger to be weighed is 0.065wt% for the total amount of the mixture; 2) prepare a H-type double-tube quartz ampoule through dehydroxylation pretreatment, such as figure 1 As shown, the H-type double-tube quartz ampoule includes a glass raw material tube A and a purified glass tube B, the glass raw material tube A and the purified glass tube B communicate through a connecting tube C, and the upper ends of the glass raw material tube A and the purified glass tube B are opened respectively; The mixture obtained in step 1) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com