Europium ion activated silicon phosphate green fluorescent powder and its preparation method

A green phosphor, silicophosphate technology, applied in the field of ultraviolet-near ultraviolet type white light LED, can solve the problems of poor stability that cannot meet the requirements of white light LED applications, poor luminescence stability of phosphors, easy deliquescence, etc., and is suitable for continuous Chemical production, good luminous intensity, not easy to deliquescence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

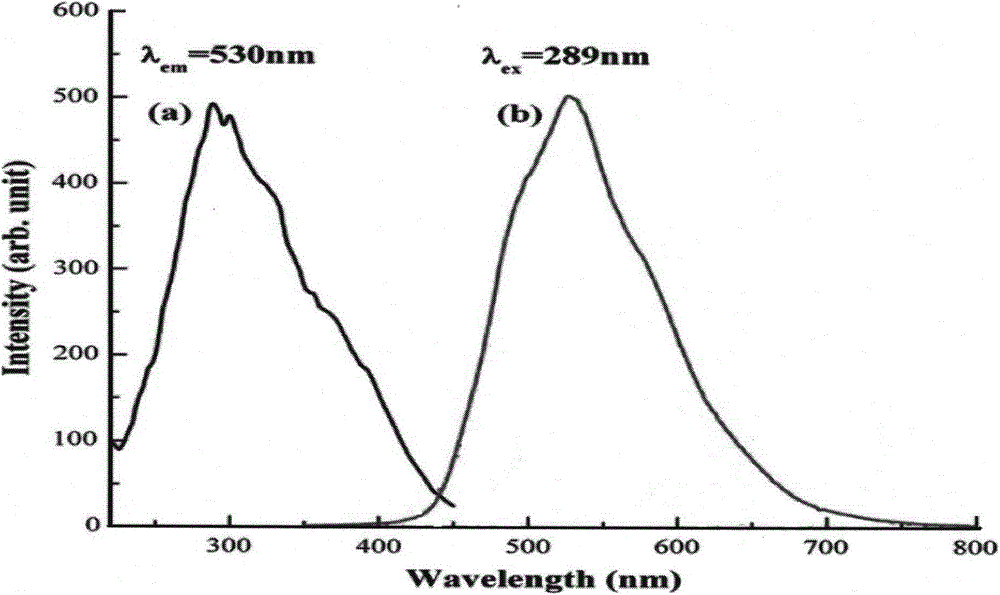

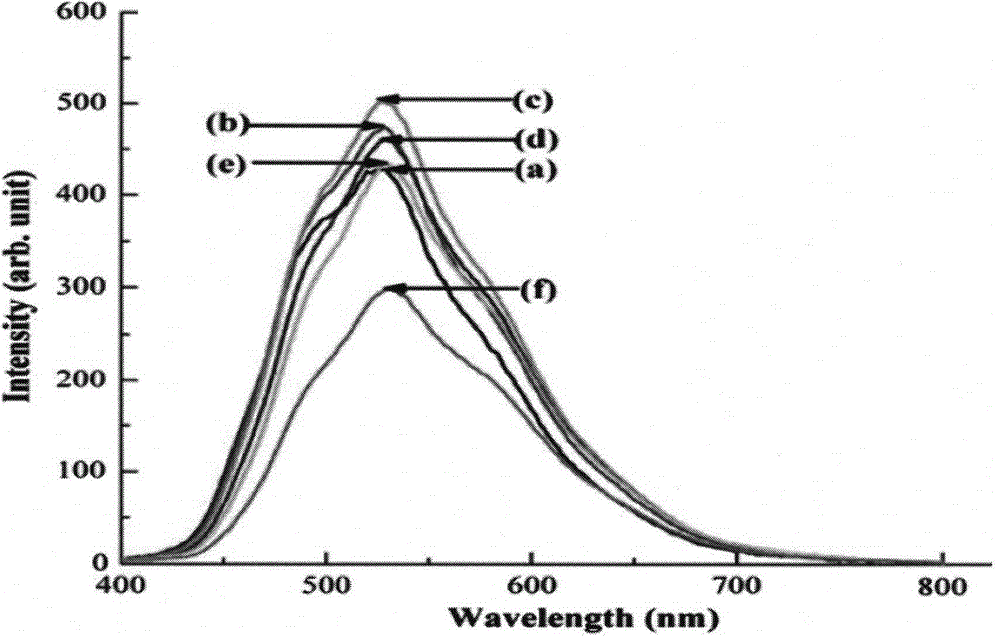

[0025] Implementation Example 1: Ca 4.9875 (PO 4 ) 2 SiO 4 : 0.0125Eu 2+ preparation of

[0026] First, according to the chemical formula Ca 4.9875 (PO 4 ) 2 SiO 4 : 0.0125Eu 2+ The stoichiometric ratio of the reaction raw material Eu 2 o 3 , CaO, SiO 2 , NH 4 h 2 (PO 4 ) in a molar ratio of 0.00625: 4.9875: 1: 2, after ball milling for 24 hours and mixing uniformly, the mixture was put into a crucible for the first calcination, the calcination temperature was 600°C, and the calcination time was 6 hours; naturally cooled to room temperature After that, remove the sample. After the raw materials calcined for the first time are ball-milled and mixed evenly again, the mixture is put into a crucible and calcined for the second time under a nitrogen-hydrogen mixed reducing atmosphere. The calcining temperature is 1300°C, and the calcining time is 8 hours. The sample was post-processed to obtain silicon phosphate green phosphor.

Embodiment 2

[0027] Implementation Example 2: Ca 4.975 (PO 4 ) 2 SiO 4 : 0.025Eu 2+ preparation of

[0028] First, according to the chemical formula Ca 4.975 (PO 4 ) 2 SiO 4 : 0.025Eu 2+ The stoichiometric ratio of the reaction raw material Eu(NO 3 ) 3 , CaCO 3 , SiO 2 , (NH 4 ) 3 (PO 4 ) in a molar ratio of 0.025: 4.975: 1: 2, after ball milling for 24 hours and mixing uniformly, the mixture was put into a crucible for the first calcination, the calcination temperature was 650°C, and the calcination time was 5 hours; naturally cooled to room temperature After that, remove the sample. After the raw materials calcined for the first time are ball milled and mixed evenly again, the mixture is put into a crucible and calcined for the second time under a mixed reducing atmosphere of nitrogen and hydrogen. The calcining temperature is 1350°C, and the calcining time is 7 hours. The sample was post-processed to obtain silicon phosphate green phosphor.

Embodiment 3

[0029] Implementation Example 3: Ca 4.95 (PO 4 )2 SiO 4 : 0.05Eu 2+ preparation of

[0030] First, according to the chemical formula Ca 4.95 (PO 4 ) 2 SiO 4 : 0.05Eu 2+ The stoichiometric ratio of the reaction raw material Eu 2 o 3 , CaCO 3 , SiO 2 , NH 4 h 2 (PO 4 ) in a molar ratio of 0.025: 4.95: 1: 2, after ball milling for 24 hours and mixing uniformly, the mixture was put into a crucible for the first calcination, the calcination temperature was 700°C, and the calcination time was 4 hours; naturally cooled to room temperature After that, remove the sample. After the raw materials calcined for the first time are ball-milled and mixed evenly again, the mixture is put into a crucible and calcined for the second time under a nitrogen-hydrogen mixed reducing atmosphere. The calcining temperature is 1400°C, and the calcining time is 7 hours. The sample was post-processed to obtain silicon phosphate green phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com