Zinc-aluminum alloy surface treatment process

A surface treatment, zinc-aluminum alloy technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve problems such as high cost and complex process, and achieve easy control, environmental friendliness, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

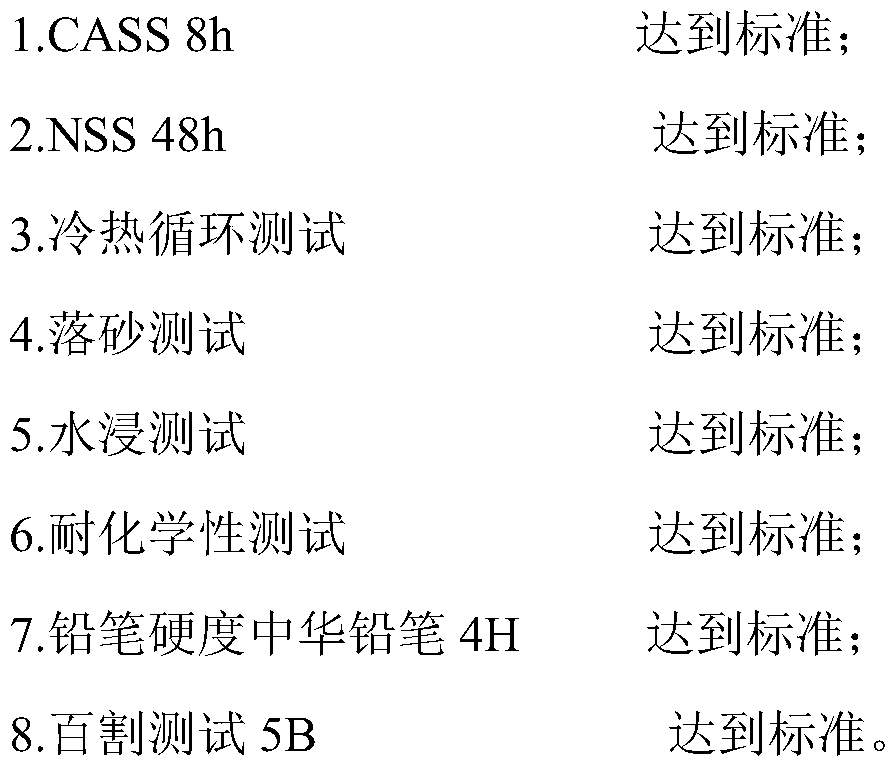

Examples

Embodiment 1

[0037] This embodiment provides a zinc aluminum alloy surface treatment process, which includes the following steps:

[0038] Step 1: Polish the alloy matrix;

[0039] Step 2: Dewax, degrease, and rust the alloy matrix;

[0040] Step 3: Multi-step vacuum coating on the alloy substrate, as follows:

[0041] (1) Transfer the cleaned workpiece into a vacuum furnace, and evacuate the vacuum furnace to the body vacuum, the vacuum degree is 7.0×10-3Pa, then argon gas is introduced, and the bias is turned on when the vacuum degree reaches 1.0Pa~2.0Pa The piezoelectric power supply performs glow cleaning on the surface of the workpiece. The process parameters adopted are: the bias voltage is 1000V, the duty cycle is 60%, and the current is 3.0A;

[0042] (2) Use magnetron sputtering to deposit the transition layer: evacuate the vacuum furnace to the body vacuum, and then pass in argon to make the vacuum reach 0.4Pa, and then use intermediate frequency magnetron sputtering to deposit the first ...

Embodiment 2

[0048] This embodiment provides a zinc aluminum alloy surface treatment process, which includes the following steps:

[0049] Step 1: Polish the alloy matrix;

[0050] Step 2: Dewax, degrease, and rust the alloy matrix;

[0051] Step 3: Multi-step vacuum coating on the alloy substrate, as follows:

[0052] (1) Transfer the cleaned workpiece into a vacuum furnace, evacuate the vacuum furnace to the body vacuum, the vacuum degree is 8.0×10-3Pa, and then pass in argon gas, turn on the bias power supply when the vacuum degree reaches 1.0Pa Glow cleaning on the surface of the workpiece, the process parameters adopted are: the bias voltage is 500V, the duty cycle is 60%, and the current is 2.0A;

[0053] (2) Use magnetron sputtering to deposit the transition layer: evacuate the vacuum furnace to the body vacuum, and then pass in argon to make the vacuum reach 0.35Pa, and then use intermediate frequency magnetron sputtering to deposit the first metal chromium layer, deposition time For 5min,...

Embodiment 3

[0059] This embodiment provides a zinc aluminum alloy surface treatment process, which includes the following steps:

[0060] Step 1: Polish the alloy matrix;

[0061] Step 2: Dewax, degrease, and rust the alloy matrix;

[0062] Step 3: Multi-step vacuum coating on the alloy substrate, as follows:

[0063] (1) Transfer the cleaned workpiece into a vacuum furnace, evacuate the vacuum furnace to the body vacuum, the vacuum degree is 8.0×10-3Pa, then pass in argon gas, turn on the bias power supply when the vacuum degree reaches 1.5Pa Glow cleaning on the surface of the workpiece, the process parameters adopted are: the bias voltage is 500V, the duty cycle is 60%, and the current is 3.0A;

[0064] (2) The transition layer is deposited by magnetron sputtering: the vacuum furnace is evacuated to the main vacuum, and then argon gas is introduced to make the vacuum degree reach 0.45Pa, and then the first metal chromium layer is deposited by medium frequency magnetron sputtering, the depositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com