A kind of nylon composite material containing secondary surface modified filler and its preparation method

A nylon composite material and a composite material technology are applied in the field of nylon composite materials containing secondary surface modified fillers and their preparation, which can solve the problems of poor mechanical properties of composite materials, poor compatibility of substrates, etc., and increase the interface bonding force. , The effect of improving mechanical properties and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

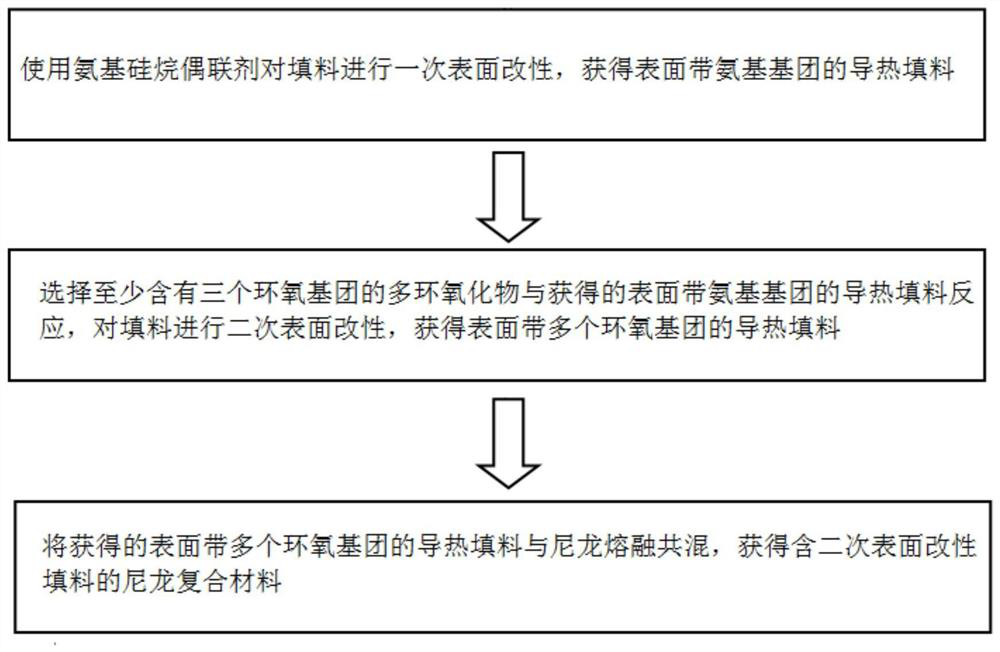

[0040] Please also refer to Figure 1-3 Shown, the present invention also provides a kind of preparation method of the nylon composite material containing secondary surface modification filler, it comprises the following steps at least:

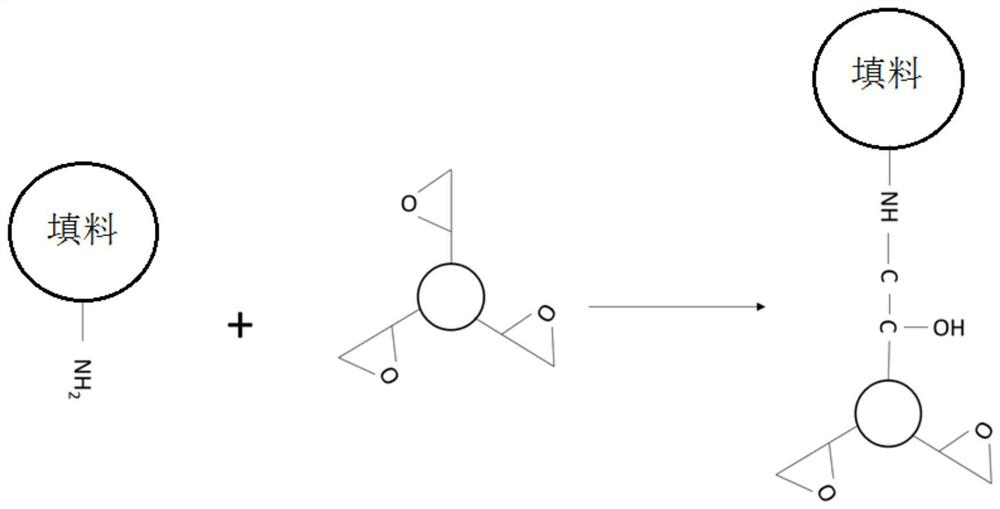

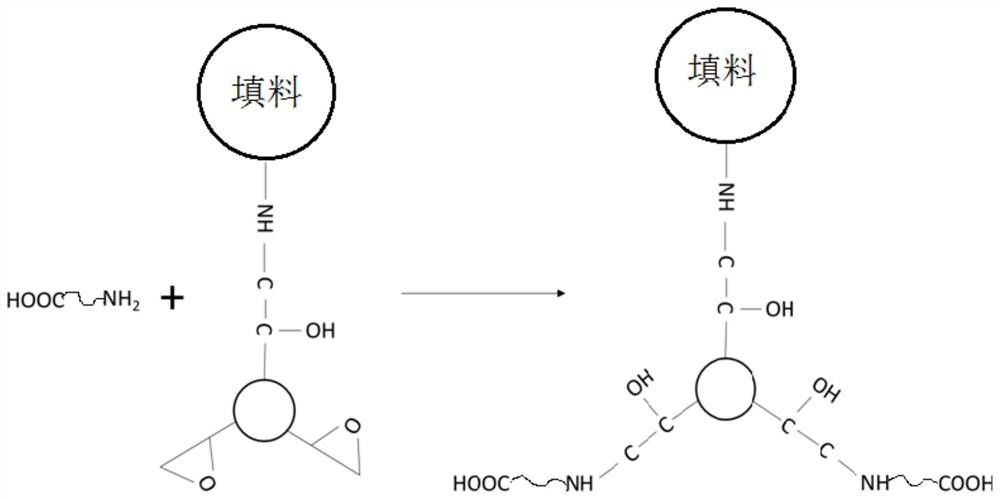

[0041] S1 uses an aminosilane coupling agent to modify the filler surface once. In order to make the aminosilane coupling agent have a larger grafting rate, the aminosilane coupling agent is weighed according to 1%-1.5% of the mass of the thermally conductive filler. The aminosilane coupling agent can be one of 3-aminopropyltrimethoxysilane, 3-aminopropyltriethoxysilane, N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane species or several. Mix the aminosilane coupling agent with ethanol and water, and the molar amount of ethanol is 4-5 times that of the aminosilane coupling agent. In this range, the aminosilane coupling agent can be fully diluted to effectively expand the aminosilane coupling agent. The distance between the linker molecules. ...

Embodiment 1

[0047] Mix 20 g (0.09 mol) of 3-aminopropyltriethoxysilane with 0.45 mol of ethanol and 0.27 mol of water, and hydrolyze at 30°C for 40 minutes to obtain an aminosilane coupling agent hydrolyzate. Weigh 1000g of silicon micropowder and 1000g of boron nitride dried in an oven for 8 hours, add them to a high-speed mixer, and when the materials reach 110°C, add aminosilane coupling agent hydrolyzate evenly, and continue stirring for 50 minutes; then raise the temperature to 125°C and add 100g of iso Triglycidyl cyanurate was mixed at high speed for 60 minutes, and then dried in an oven at 105°C for 8 hours to prepare a thermally conductive filler with multiple epoxy groups on the surface.

[0048] Dry nylon 6 at 105°C in a vacuum oven for 8 hours, take 34 parts of dried nylon 6, 6 parts of nylon 1212, 60 parts of the above-mentioned thermally conductive filler with multiple epoxy groups on the surface, 0.1 part of antioxidant (antioxidant Agent 1010 and antioxidant 168 are used i...

Embodiment 2

[0050] Mix 30 g (0.14 mol) of 3-aminopropyltrimethoxysilane with 0.7 mol of ethanol and 0.42 mol of water, and hydrolyze at 30° C. for 30 min to obtain an aminosilane coupling agent hydrolyzate. Weigh 1,000g of silicon carbide and 1,000g of boron nitride dried in an oven for 8 hours, add them to a high-speed mixer, and when the materials reach 110°C, add aminosilane coupling agent hydrolyzate evenly, continue stirring for 50 minutes, then raise the temperature to 135°C, and add 80g of isocyanide Triglycidyl urate was mixed at high speed for 50 minutes, and then dried in an oven at 105°C for 8 hours to prepare a thermally conductive filler with multiple epoxy groups on the surface.

[0051] Dry nylon 6 at 105°C in a vacuum oven for 7 hours, take 44 parts of dried nylon 6, 6 parts of nylon 1012, 50 parts of the above-mentioned thermally conductive filler with multiple epoxy groups on the surface, 0.2 parts of antioxidant, 0.2 parts of bismuth Methylimidazole was added to a high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com