High-performance polymer modified asphalt waterproof coating and preparation method thereof

A high-performance polymer, modified asphalt technology, applied in asphalt coatings, chloroprene homopolymer coatings, fire-retardant coatings, etc., can solve the problems of low strength, complex production process, poor aging resistance, etc. Good aging resistance, high solid content and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

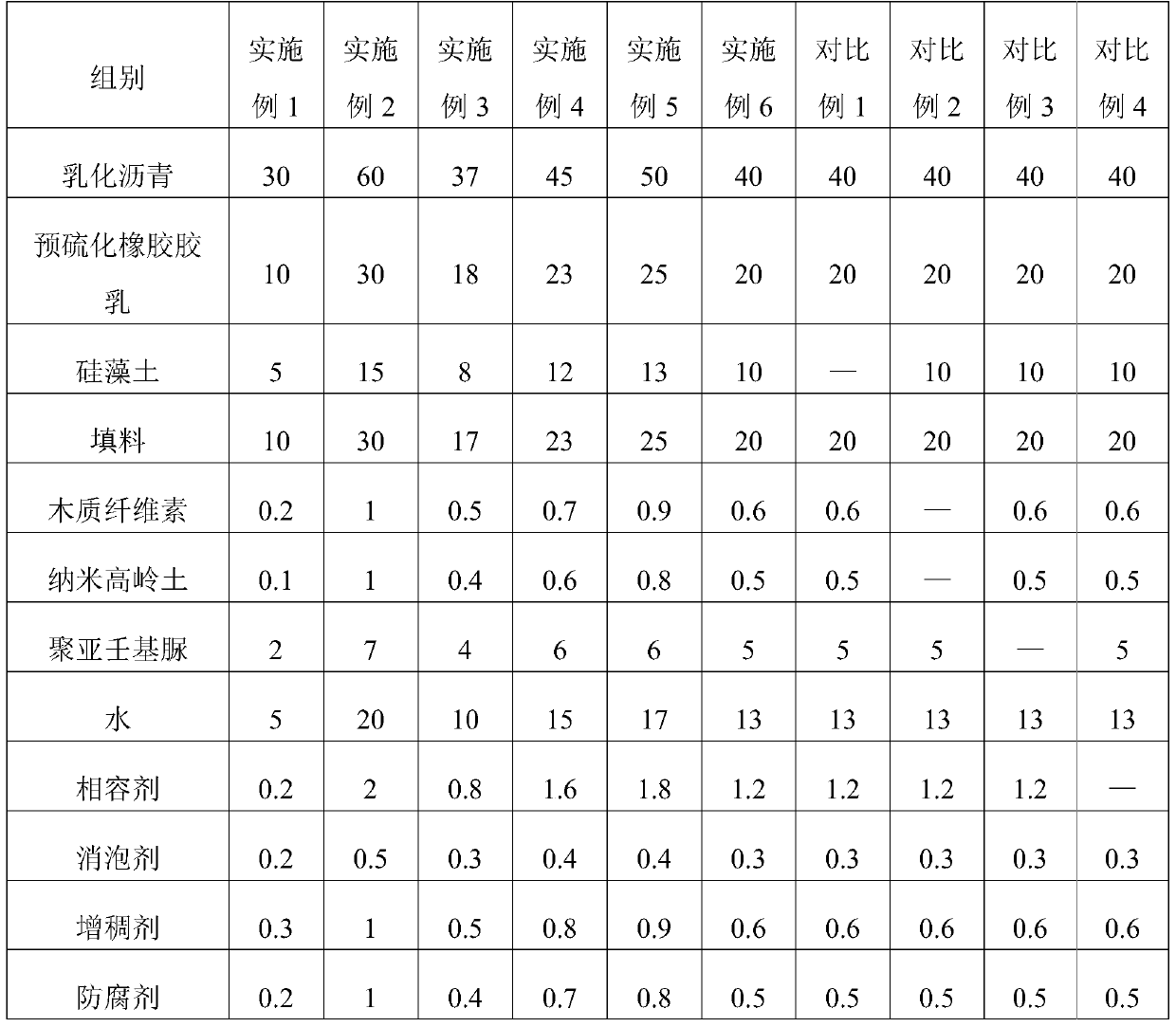

Embodiment 1

[0031] A high-performance polymer modified bitumen waterproof coating composed of the following components by weight:

[0032] 30 parts of zwitterionic emulsified asphalt, 10 parts of pre-vulcanized non-ionic neoprene latex, 5 parts of diatomaceous earth, 10 parts of heavy calcium powder, 0.2 parts of lignocellulose, 0.1 part of nanokaolin, 2 parts of polynonylurea, 5 parts of water Parts, 0.2 part of compatibilizer, 0.2 part of polysiloxane defoamer, 0.3 part of polyurethane associative thickener, 0.2 part of sodium tetraborate,

[0033] Among them, the solid content of zwitterionic emulsified asphalt is 60-70%, the solid content of pre-vulcanized non-ionic neoprene latex is 50%-60%, the fineness of diatomaceous earth is 800 mesh, and the fineness of lignocellulose is 400 mesh. The fineness of heavy calcium powder is 400 mesh to 2000 mesh, and the compatibilizer is a mixture of poloxamer, polyvinylpyrrolidone and sorbitol in a mass ratio of 1:2:1.

[0034] A preparation method of h...

Embodiment 2

[0039] A high-performance polymer modified bitumen waterproof coating composed of the following components by weight:

[0040] 60 parts of zwitterionic emulsified asphalt, 30 parts of pre-vulcanized non-ionic styrene butadiene latex, 15 parts of diatomaceous earth, 30 parts of talc, 1 part of lignocellulose, 1 part of nano kaolin, 7 parts of polynonyl urea, 20 parts of water , 2 parts of compatibilizer, 0.5 part of polysiloxane defoamer, 1 part of polyurethane associative thickener, 1 part of sodium tetraborate,

[0041] Among them, the solid content of zwitterionic emulsified asphalt is 60-70%, the solid content of pre-vulcanized non-ionic neoprene latex is 50%-60%, the fineness of diatomaceous earth is 800 mesh, and the fineness of lignocellulose is 400 mesh. The fineness of talc is 400 mesh to 2000 mesh, and the compatibilizer is a mixture of poloxamer, polyvinylpyrrolidone and sorbitol in a mass ratio of 1:2:1.

[0042] The preparation method is the same as in Example 1.

Embodiment 3

[0044] A high-performance polymer modified bitumen waterproof coating composed of the following components by weight:

[0045] 37 parts of zwitterionic emulsified asphalt, 18 parts of pre-sulfurized hydrogenated nitrile nitrile latex, 8 parts of diatomaceous earth, 17 parts of quartz powder, 0.5 part of lignocellulose, 0.4 part of nanokaolin, 4 parts of polynonylurea, 10 parts of water, 0.8 part of compatibilizer, 0.3 part of polysiloxane defoamer, 0.5 part of polyurethane associative thickener, 0.4 part of sodium tetraborate,

[0046] Among them, the solid content of zwitterionic emulsified asphalt is 60 to 70%, the solid content of pre-sulfurized hydrogenated nitrile nitrile latex is 50% to 60%, the fineness of diatomaceous earth is 800 mesh, the fineness of lignocellulose is 400 mesh, quartz The powder has a fineness of 400 mesh to 2000 mesh, and the compatibilizer is a mixture of poloxamer, polyvinylpyrrolidone and sorbitol in a mass ratio of 1:2:1.

[0047] The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com