High-strength and high-corrosion-resistance biomedical Mg-Ga alloy and preparation method thereof

A high corrosion resistance, biomedical technology, applied in the field of medical alloys, can solve the problem that the mechanical properties of materials have not been significantly improved, and achieve the effect of expanding the scope of clinical application, high strength and high corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

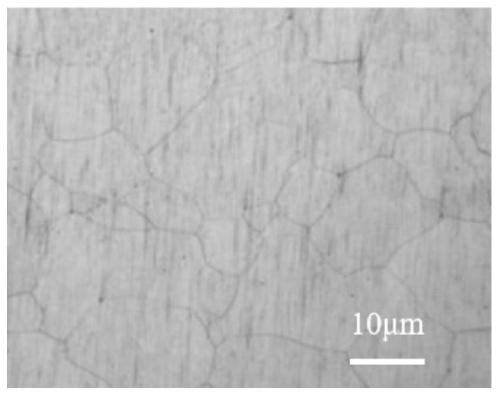

[0032] In this embodiment, the composition and weight percentage of the binary Mg-Ga alloy material are: Ga 5.0%, and the rest is Mg. The alloy contains a small amount of Mn, Si, Fe, Ni impurity elements.

[0033] The preparation method of magnesium alloy is specifically as follows:

[0034] (1) Take the raw materials pure magnesium, pure gallium and pure zinc according to the stated ratio, and the purity is not higher than 99.99wt%; (2) Cut a certain amount of pure magnesium with a thickness of 0.5-1mm and a diameter of 50-100mm from the raw materials The gallium is placed in the center of the magnesium sheet, and the gallium is wrapped into the magnesium by mechanical means;

[0035] (3) Put pure magnesium and pure magnesium wrapped with gallium in a high-strength graphite crucible, heat it in a resistance furnace, heat it up to 750-770°C and keep it warm for 3 hours, and use an ultrasonic stirrer every 15 minutes to heat the melt Perform ultrasonic stirring, stirring 8-10...

Embodiment 2

[0045] In this embodiment, the composition and weight percentage of the Mg-Ga alloy material are: Ga 7.0%, and the rest is Mg. The alloy contains a small amount of Mn, Si, Fe, Ni impurity elements.

[0046] The difference between the preparation method and Example 1 is:

[0047] The solution temperature of magnesium alloy is 430°C, the solution time is 15 hours, and then aging treatment is performed, and the aging time is 25 hours at 200°C

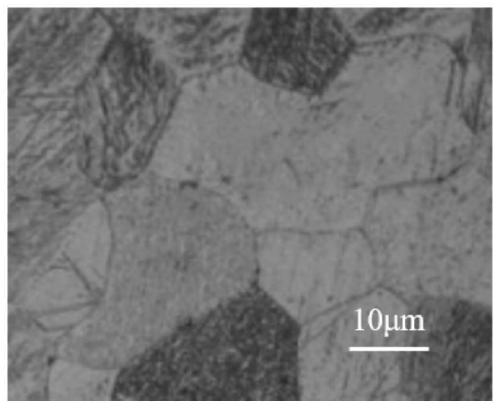

[0048] After testing, the material has good biocompatibility, the cytotoxicity rating is 0, and the average grain size is 13 μm ( image 3 ), the degradation rate of the alloy was measured to be 0.3mm / y by weight loss test. The alloy can be degraded and absorbed in biological fluid or blood environment, and its tensile strength is 305MPa, yield strength is 98MPa, and elongation at break is 19%.

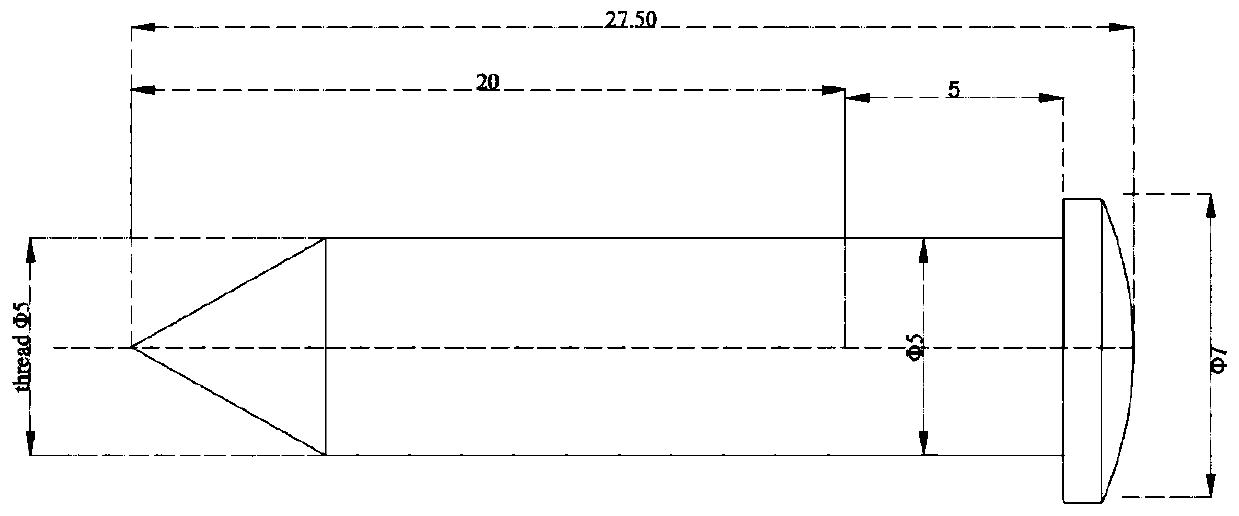

[0049] Processed from the above extruded alloys figure 2 For the screws shown, the tested screws can withstand a maximum torque of 2.73N.m. ...

Embodiment 3

[0051] In this embodiment, the composition and weight percentage of the Mg-Zn-Ga alloy material are: Ga 5.0%, Zn 1.0%, and the rest is Mg. The alloy contains a small amount of Mn, Si, Fe, Ni impurity elements.

[0052] (1) Weigh raw material pure magnesium and pure gallium according to the ratio, and the purity is not higher than 99.99wt%;

[0053] (2) Cut a certain amount of pure magnesium sheets with a thickness of 0.5-1mm and a diameter of 50-100mm from the raw material, place gallium at the center of the magnesium sheet, and mechanically wrap the gallium into the magnesium;

[0054] (3) Put pure magnesium and pure magnesium wrapped with gallium in a high-strength graphite crucible, put it into a resistance furnace and heat it to 700-720°C, after the raw materials are melted, add Zn, keep it warm for 1 hour, and then heat up to 750-770°C , keep warm for another 3 hours, and use an ultrasonic stirrer to ultrasonically stir the melt every 15 minutes at the beginning of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com